This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

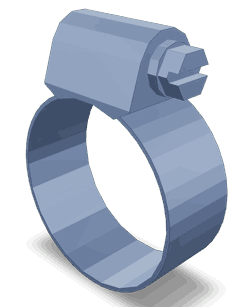

The Cummins Hose Clamp 3922850 is a specialized component designed for use in commercial truck maintenance. It plays a role in ensuring the integrity of hose connections within various truck systems, contributing to the overall efficiency and reliability of the vehicle.

Basic Concepts of Hose Clamps

Hose clamps are mechanical devices used to secure hoses to fittings, ensuring a tight and leak-free connection. They are integral in systems where fluid transfer is necessary, such as fuel, coolant, and hydraulic systems. Hose clamps are typically constructed from materials like metal, plastic, or rubber, chosen for their durability and resistance to environmental factors 1.

Purpose of the Cummins Hose Clamp 3922850

The Cummins Hose Clamp 3922850 is specifically engineered to maintain secure connections in commercial truck applications. It is utilized in various systems including fuel lines, coolant systems, and hydraulic circuits. By providing a reliable seal, it helps prevent leaks and ensures the consistent flow of fluids, which is important for the proper operation of the truck.

Key Features

The Cummins Hose Clamp 3922850 boasts several key features that enhance its performance. Its design incorporates a robust construction that can withstand the rigors of commercial truck use. The clamp is made from high-quality materials, ensuring durability and resistance to corrosion. Additionally, it features a unique band design that provides even pressure distribution across the hose, enhancing the seal quality.

Benefits of Using Cummins Hose Clamp 3922850

Employing the Cummins Hose Clamp 3922850 offers several advantages. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The design allows for easy installation, minimizing downtime during maintenance procedures. Furthermore, its reliable sealing capability helps maintain system integrity, contributing to the overall performance and safety of the truck.

Installation Process

Installing the Cummins Hose Clamp 3922850 involves several steps to ensure a proper seal. Begin by cleaning the hose and fitting to remove any debris. Slide the clamp onto the hose, ensuring it is positioned correctly. Use a clamp tool to tighten the band evenly around the hose and fitting. It is important to achieve the correct tension to ensure a secure seal without damaging the hose.

Troubleshooting Common Issues

Common issues with hose clamps include leaks and improper sealing. These problems can often be traced to incorrect installation or wear and tear on the clamp. To address leaks, inspect the clamp for proper tension and ensure there is no damage to the hose or fitting. If necessary, replace the clamp to restore a secure connection.

Maintenance Tips

Regular maintenance of the Cummins Hose Clamp 3922850 is important for ensuring its longevity and performance. Inspect the clamp during routine maintenance checks for signs of wear or corrosion. Replace the clamp if any damage is detected to prevent potential leaks. Additionally, ensure that the clamp is tightened to the manufacturer’s specifications to maintain an effective seal.

Compatibility and Applications

The Cummins Hose Clamp 3922850 is designed for use in various commercial truck systems. It is compatible with a range of hose sizes and materials, making it versatile for different applications. When integrating the clamp into a system, consider the specific requirements of the application to ensure optimal performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its commitment to quality and innovation. The company’s extensive product range includes components like the Hose Clamp 3922850, which are engineered to meet the demanding requirements of commercial vehicles 2.

Cummins Hose Clamp 3922850 Compatibility

The Cummins Hose Clamp 3922850 is a versatile component designed to fit seamlessly with various Cummins engines, ensuring a secure and leak-proof connection for hoses and other related parts. This part is engineered to meet the rigorous demands of the engines it supports, providing reliable performance and durability.

Engine Compatibility

6B5.9 Engine

The 6B5.9 engine is one of the models that benefit from the 3922850 Hose Clamp. This clamp is specifically designed to fit the hoses and connections on the 6B5.9, ensuring that all fluid lines and air passages maintain their integrity. Its robust construction and precise fitment make it an important component for maintaining the operational efficiency of the 6B5.9 engine.

6C8.3 Engine

Similarly, the 6C8.3 engine is another model that utilizes the 3922850 Hose Clamp. This clamp is engineered to fit the specific hose connections on the 6C8.3, providing a secure seal that prevents leaks and ensures the engine operates smoothly. The compatibility of this part with the 6C8.3 engine highlights its versatility and importance in maintaining the engine’s performance.

Grouped Compatibility

When considering the 6B5.9 and 6C8.3 engines together, it is clear that the 3922850 Hose Clamp is designed to fit both models effectively. This compatibility underscores the clamp’s versatility and its ability to meet the needs of multiple engine types within the Cummins lineup. The precise engineering of this part ensures that it can be used interchangeably across these engines, providing a reliable solution for securing hoses and connections.

Role of Part 3922850 Hose Clamp in Engine Systems

The part 3922850 Hose Clamp is an important component in the secure and efficient operation of various engine systems. Its primary function is to ensure a tight and reliable connection between hoses and fittings, which is vital for maintaining the integrity of fluid transfer within the engine.

Turbocharger Systems

In turbocharger arrangements, the Hose Clamp is used to secure connections between the turbocharger and the intercooler or charge air cooler. This ensures that the pressurized air from the turbocharger is efficiently transferred to the engine, enhancing performance and reliability.

Cooling Systems

Within the engine’s cooling system, the Hose Clamp plays a significant role in securing connections at the water inlet and outlet of the radiator. It ensures that coolant flows smoothly through the system, maintaining optimal engine temperature and preventing leaks that could lead to overheating.

Heat Exchanger Applications

In heat exchanger setups, the Hose Clamp is employed to secure connections between the exchanger and the plumbing system. This is particularly important in marine engines where seawater is used as a coolant. The clamp ensures that the seawater flows efficiently through the heat exchanger, facilitating effective heat dissipation.

General Plumbing and Connections

Across various plumbing connections within the engine, the Hose Clamp provides a consistent and secure fit. Whether connecting hoses to the shield around high-temperature components or ensuring the integrity of connections in the turbocharger location, the clamp contributes to the overall reliability and performance of the engine system.

Conclusion

The Cummins Hose Clamp 3922850 is a critical component for maintaining the integrity and efficiency of commercial truck systems. Its robust design, compatibility with various engine models, and ease of installation make it a valuable asset in ensuring the reliable operation of truck systems. Regular maintenance and proper installation are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.