This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

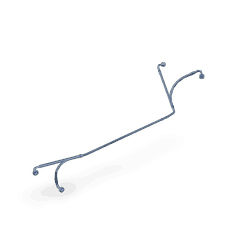

The Cummins 3649890 Flexible Hose is a component designed for use in commercial trucks. It serves as a vital link in various systems within these vehicles, facilitating the transfer of fluids and contributing to the overall efficiency and reliability of truck operations.

Basic Concepts of Flexible Hoses

Flexible hoses are utilized in automotive applications to connect different parts of a system that may move or vibrate relative to each other. They are engineered to withstand the dynamic conditions within an engine compartment, providing a durable yet flexible conduit for fluids such as coolant, fuel, or hydraulic fluid 1. The flexibility of these hoses allows for movement and reduces the transmission of vibrations, which can otherwise lead to wear and failure of rigid connections.

Purpose of the Cummins 3649890 Flexible Hose

The Cummins 3649890 Flexible Hose is specifically designed to connect components within a truck’s system, enabling the transport of fluids under varying pressures and temperatures. It plays a role in maintaining the integrity of fluid pathways, ensuring that systems operate efficiently without leaks or disruptions 2.

Key Features

This Cummins part is characterized by its material composition, which typically includes synthetic rubber and reinforcement materials to enhance durability and flexibility. Its design specifications are tailored to meet the demanding conditions of commercial truck environments, providing a balance between flexibility and strength. The hose’s construction allows it to accommodate movement and vibration, reducing stress on connected components 3.

Benefits of Using the 3649890 Flexible Hose

Utilizing the Cummins 3649890 Flexible Hose offers several advantages. It effectively reduces the transmission of vibrations from the engine to other parts of the truck, which can help in minimizing wear on connected components. Its durable construction contributes to longevity, while its flexibility simplifies the installation process. Additionally, the hose’s design facilitates easier maintenance and replacement when necessary 4.

Installation Considerations

When installing the Cummins 3649890 Flexible Hose, it is important to ensure proper alignment with the components it connects. Securement methods should be employed to prevent disconnection under operational conditions. Compatibility with existing systems must be verified to ensure seamless integration and optimal performance 5.

Maintenance and Troubleshooting

Regular maintenance of the 3649890 Flexible Hose involves inspecting for signs of wear, checking for leaks, and ensuring that connections remain secure. Troubleshooting common issues such as leaks or connectivity problems may involve replacing worn sections of the hose or adjusting connections to ensure a proper fit.

Performance in Various Conditions

The Cummins 3649890 Flexible Hose is engineered to perform under a range of operating conditions, including extreme temperatures, high pressure, and exposure to corrosive environments. Its material composition and design specifications are selected to withstand these challenges, ensuring reliable operation in diverse truck applications 6.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and aftermarket parts. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality and innovation. The company’s extensive product range and focus on customer satisfaction underscore its position as a trusted provider of truck components.

Role of Part 3649890 Flexible Hose in Plumbing and Turbocharger Coolant Systems

Plumbing Systems

In plumbing systems, the 3649890 Flexible Hose is employed to connect various components that facilitate the flow of fluids, such as water, oil, or coolant. This hose allows for the necessary flexibility to accommodate the movement and vibrations that occur within the system. Its application ensures that connections remain secure and leak-free, even under dynamic conditions. The hose is often used to link pumps to heat exchangers, radiators to engines, and various other fluid transfer points where rigid piping would be impractical.

Turbocharger Coolant Systems

Within turbocharger coolant systems, the 3649890 Flexible Hose plays a significant role in maintaining the integrity and efficiency of the cooling process. Turbochargers operate under extreme temperatures, and effective cooling is essential to prevent damage and ensure optimal performance. The flexible hose is utilized to connect the turbocharger to the engine’s coolant system, allowing for the circulation of coolant that absorbs heat from the turbocharger. This setup helps in dissipating heat away from the turbocharger, thus protecting its components from thermal stress. The flexibility of the hose is particularly beneficial in this application, as it can withstand the high pressures and temperatures associated with turbocharger operations while accommodating the mechanical movements of the engine.

Conclusion

The Cummins 3649890 Flexible Hose is a critical component in the operation of commercial trucks, offering durability, flexibility, and efficient fluid transfer across various systems. Its design and material composition are tailored to withstand the demanding conditions of truck environments, ensuring reliable performance and longevity. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall efficiency and reliability of truck operations.

-

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩ -

Jazar, R. N. (2017). Vehicle Dynamics: Theory and Application. Springer.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISF2.8 CM2220 F117. Bulletin Number 4388579.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.