This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3643998 Molded Hose is a specialized component designed for use in commercial trucks. It serves a vital function in the vehicle’s fluid transport systems, ensuring the efficient operation of various truck systems. Understanding its purpose and significance is key to maintaining the overall performance and reliability of commercial trucks.

Basic Concepts of Molded Hoses

Molded hoses are integral components in automotive systems, constructed through a process that involves molding synthetic rubber or other materials around a textile or wire reinforcement. This construction method provides molded hoses with flexibility, durability, and resistance to various environmental factors. They are commonly used in automotive applications to transport fluids such as coolant, fuel, and hydraulic fluid, playing a role in the operation of engines and other systems 1.

Purpose of the 3643998 Molded Hose

The Cummins 3643998 Molded Hose is specifically designed to connect various systems within a truck, facilitating the transport of fluids essential for the truck’s operation. It is engineered to withstand the pressures and temperatures associated with these fluids, ensuring reliable performance under demanding conditions.

Key Features

This Cummins part boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that offer resistance to wear, tear, and environmental factors. Its design includes reinforced ends for secure connections and flexibility in the hose body to accommodate movement and vibration within the truck’s engine compartment.

Benefits of Using the 3643998 Molded Hose

Utilizing the 3643998 Molded Hose offers several advantages. Its robust construction and design contribute to improved reliability and longevity, reducing the likelihood of leaks and failures. This can lead to potential cost savings over time by minimizing the need for frequent replacements and repairs.

Installation Considerations

Proper installation of this part is crucial for ensuring its optimal performance and longevity. It is recommended to follow manufacturer guidelines for installation, which may include using specific tools and procedures to ensure secure and leak-free connections. Attention to detail during installation can prevent common issues such as leaks or premature degradation.

Maintenance and Troubleshooting

Routine maintenance of the 3643998 Molded Hose is important for its continued reliable operation. This may include regular inspections for signs of wear, damage, or leaks. Troubleshooting common issues such as leaks or degradation can often be addressed through proper maintenance practices, including timely replacement of worn or damaged hoses.

Compatibility and Usage

The 3643998 Molded Hose is designed for use in various truck models and configurations, offering compatibility with a range of systems within commercial trucks. Its versatile design and construction make it suitable for a wide array of applications, ensuring it can meet the demands of different truck operations.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles 2.

Role of Part 3643998 Molded Hose in Engine Systems

The molded hose, identified by part number 3643998, is a component in the efficient operation of various engine systems. Its primary function is to facilitate the smooth transfer of fluids and gases between different parts of the engine, ensuring optimal performance and reliability.

Breather System Integration

In the breather system, the molded hose plays a role by connecting the crankcase to the air intake system. This connection allows for the release of pressure build-up within the crankcase, which is vital for maintaining a stable environment for the engine’s moving parts. The hose ensures that any excess gases or vapors are vented effectively, preventing contamination of the engine oil and reducing the risk of oil foaming. This, in turn, helps in preserving the lubrication quality and extending the lifespan of the engine components.

Crankcase Ventilation

Within the crankcase ventilation system, the molded hose is responsible for directing blow-by gases—a mixture of unburned fuel, combustion byproducts, and moisture—away from the crankcase. These gases are routed back into the intake manifold, where they are re-burned in the combustion chamber. This process not only enhances fuel efficiency but also reduces emissions, contributing to a cleaner and more environmentally friendly operation of the engine.

System Reliability and Maintenance

The use of a high-quality molded hose like part 3643998 ensures that the connections within these systems are secure and durable. This reliability is paramount in preventing leaks, which can lead to performance issues and potential damage to the engine. Regular inspection and maintenance of the hose are recommended to ensure it remains in optimal condition, thereby supporting the overall efficiency and longevity of the engine systems it serves 3.

Conclusion

The Cummins 3643998 Molded Hose is a critical component in the maintenance and operation of commercial trucks. Its design and features contribute to the efficient transport of fluids within the truck’s systems, ensuring reliable performance and longevity. Proper installation, maintenance, and understanding of its role in engine systems are essential for maximizing the benefits of this part.

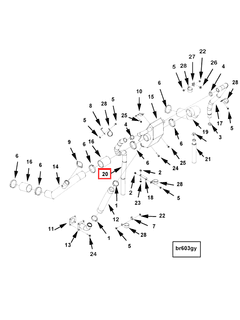

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.