This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

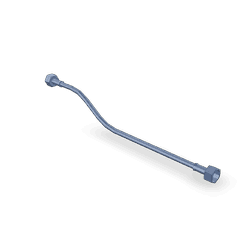

The Cummins 3426513 Flexible Hose is a component designed for use in commercial trucks. It serves as a conduit for various fluids within the truck’s systems, facilitating the transfer of these fluids between different parts of the vehicle. Its application is crucial for maintaining the operational efficiency of the truck 1.

Basic Concepts of Flexible Hoses

Flexible hoses are tubes made from materials that allow them to bend and flex without breaking. In automotive applications, they are used to connect different parts of a system that may move relative to each other. Flexible hoses function by providing a pathway for fluids to travel, accommodating the movement and vibration that occur during vehicle operation 2.

Purpose of the 3426513 Flexible Hose

The Cummins 3426513 Flexible Hose is specifically designed to connect various systems within a truck, allowing for the transport of fluids such as coolant, fuel, or hydraulic fluid. It plays a role in ensuring that these fluids can move between components that may not be fixed in relation to each other, thus supporting the overall function of the truck’s systems 3.

Key Features

The 3426513 Flexible Hose is characterized by several primary features that enhance its performance and longevity. These include its material composition, which is designed to withstand the pressures and temperatures of the fluids it transports. Its flexibility allows it to accommodate the movement of connected components, while its durability ensures it can resist wear and tear over time. Design elements such as reinforced ends or specific bend radii may also be incorporated to improve its functionality 4.

Benefits of Using the 3426513 Flexible Hose

Utilizing the Cummins 3426513 Flexible Hose offers several advantages. Its flexibility over rigid hoses allows for greater accommodation of movement and vibration, which can reduce the risk of damage to the hose or connected systems. This flexibility can also contribute to reduced maintenance needs, as the hose is less likely to suffer from stress-related failures 5.

Installation Considerations

When installing the Cummins 3426513 Flexible Hose, it is important to follow guidelines and best practices to ensure proper function and longevity. This includes aligning the hose correctly with the systems it connects, using appropriate securing methods to hold it in place, and verifying compatibility with existing systems to prevent issues such as leaks or improper fluid flow 6.

Troubleshooting Common Issues

Flexible hoses, including the Cummins 3426513, may encounter problems such as leaks or kinks. Identifying these issues early is important for maintaining the efficiency of the truck’s systems. Approaches for diagnosing and resolving these issues may involve inspecting the hose for signs of wear or damage, ensuring proper installation, and replacing the hose if necessary 7.

Maintenance Tips

Maintaining the Cummins 3426513 Flexible Hose involves regular inspection routines to check for signs of wear or damage. This can help identify potential issues before they lead to more significant problems. Knowing when to consider replacement based on the condition of the hose can also contribute to the ongoing efficiency and reliability of the truck’s systems 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, and automotive markets. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of various applications 9.

Role of Part 3426513 Flexible Hose in Engine Systems

In the intricate network of an engine system, the part 3426513 Flexible Hose serves as a vital conduit, facilitating the smooth operation of several key components. This hose is instrumental in managing the flow between the engine coolant vent and the engine coolant system.

Engine Coolant Vent

The engine coolant vent plays a significant role in maintaining the pressure balance within the coolant system. The flexible hose ensures that any excess pressure is effectively vented, preventing potential damage to the engine components. By providing a reliable pathway for venting, the hose helps in sustaining optimal pressure levels, which is essential for the efficient operation of the cooling system 10.

Vent

In addition to the coolant vent, the flexible hose also connects to other venting components within the engine system. These vents are designed to release built-up gases and pressure, ensuring that the engine operates within safe parameters. The hose’s flexibility allows it to accommodate the dynamic movements and vibrations inherent in engine operation, thereby enhancing the durability and reliability of the venting system 11.

Engine Coolant

The primary function of the engine coolant system is to regulate the engine’s temperature, preventing overheating and ensuring consistent performance. The flexible hose plays a key role in this system by providing a durable and flexible connection between various coolant passages. This ensures that coolant can flow freely and efficiently throughout the engine, absorbing heat and dissipating it through the radiator. The hose’s ability to withstand high temperatures and pressures makes it an indispensable component in maintaining the engine’s thermal management 12.

Conclusion

In summary, part 3426513 Flexible Hose is integral to the functioning of the engine coolant vent, venting components, and the overall engine coolant system. Its design and material properties ensure that it can handle the demanding conditions within an engine, contributing to the system’s reliability and efficiency.

-

Bruce P. Minaker, Fundamentals of Vehicle Dynamics and Modelling, John Wiley Sons, 2019.

↩ -

Hans B. Pacejka, Tyre and Vehicle Dynamics, Butterworth-Heinemann, 2006.

↩ -

Thomas D. Gillespie, Fundamentals of Vehicle Dynamics, SAE International, 2021.

↩ -

Cummins Inc., Fault Code Troubleshooting Manual, Bulletin Number 5612996, ISB6.7 CM2150 (EPA 2007).

↩ -

Bruce P. Minaker, Fundamentals of Vehicle Dynamics and Modelling, John Wiley Sons, 2019.

↩ -

Thomas D. Gillespie, Fundamentals of Vehicle Dynamics, SAE International, 2021.

↩ -

Cummins Inc., Fault Code Troubleshooting Manual, Bulletin Number 5612996, ISB6.7 CM2150 (EPA 2007).

↩ -

Hans B. Pacejka, Tyre and Vehicle Dynamics, Butterworth-Heinemann, 2006.

↩ -

Cummins Inc., Fault Code Troubleshooting Manual, Bulletin Number 5612996, ISB6.7 CM2150 (EPA 2007).

↩ -

Bruce P. Minaker, Fundamentals of Vehicle Dynamics and Modelling, John Wiley Sons, 2019.

↩ -

Hans B. Pacejka, Tyre and Vehicle Dynamics, Butterworth-Heinemann, 2006.

↩ -

Thomas D. Gillespie, Fundamentals of Vehicle Dynamics, SAE International, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.