This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3426490 Flexible Hose is a component designed for use in commercial trucks. It serves a specific function within the truck’s systems, facilitating the transfer of fluids and contributing to the overall operation and efficiency of the vehicle.

Basic Concepts of Flexible Hoses

Flexible hoses are components used in various automotive systems to transport fluids such as coolant, fuel, and hydraulic fluid. They are designed to accommodate movement and vibration, which are common in vehicle operations. Flexible hoses allow for more dynamic connections between components compared to rigid pipes, reducing the risk of damage from mechanical stress 1.

Purpose of the Cummins 3426490 Flexible Hose

This Cummins part is utilized in commercial trucks to connect specific systems and transport fluids. It plays a role in ensuring that fluids are efficiently moved between components, which is vital for the proper functioning of the truck. This hose is engineered to withstand the pressures and temperatures associated with its intended applications, ensuring reliable performance.

Key Features

This part is characterized by several key features that enhance its performance. These include its material composition, which is selected for durability and resistance to the fluids it transports. The hose’s flexibility allows it to accommodate the movement and vibration inherent in truck operations, while its design elements ensure a secure connection to other system components.

Benefits

Using this part offers several benefits. It contributes to improved system reliability by providing a flexible connection that can withstand the dynamic conditions of truck operation. The hose’s design reduces the risk of leaks, which can occur with rigid connections. Additionally, its durability ensures long-term performance, offering a more robust solution compared to less durable hose options 2.

Installation Considerations

Proper installation of this part is important for ensuring its effectiveness and longevity. It is designed to be compatible with specific system components, and following manufacturer guidelines for installation is recommended. Best practices include ensuring a secure connection to prevent leaks and verifying that the hose is routed to avoid abrasion or damage from moving parts.

Troubleshooting Common Issues

Common issues with flexible hoses may include leaks or signs of wear. Troubleshooting these problems involves inspecting the hose for damage, ensuring connections are secure, and checking for signs of fluid leakage. Addressing these issues promptly can help maintain the efficiency and safety of the truck’s systems.

Maintenance Tips

Regular maintenance of this part is important for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, checking connections for leaks, and following manufacturer guidelines for replacement intervals. Proper maintenance helps prevent unexpected failures and ensures the hose continues to perform its intended function effectively.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins plays a significant role in the manufacturing of automotive components, including the Cummins 3426490 Flexible Hose. The company’s focus on quality and performance is evident in its product offerings, which are designed to meet the demanding requirements of commercial vehicle applications.

Cummins Part 3426490: Flexible Hose Compatibility with Cummins Engines

This part is designed to integrate seamlessly with various Cummins engines, ensuring optimal performance and reliability. It is engineered to meet the stringent demands of the engines it supports, providing a durable and flexible solution for fluid transfer and management.

QSV91G and QSW/QSV82 Engines

For the QSV91G and QSW/QSV82 engines, the Flexible Hose part 3426490 is a critical component in the engine’s fluid management system. Its design allows for flexibility and movement, accommodating the dynamic nature of engine operation while maintaining a secure connection. This flexibility is particularly important in environments where the engine is subject to vibration and movement, ensuring that the hose does not fail under stress.

The hose is crafted from high-quality materials that resist wear and degradation, extending its lifespan and maintaining its performance over time. Its compatibility with these engines ensures that it can handle the specific pressures and temperatures encountered in these applications, providing a reliable connection that does not leak or degrade.

Integration and Installation

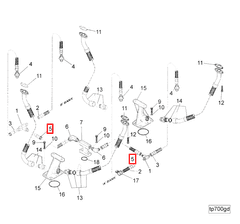

When integrating the Flexible Hose part 3426490 with the QSV91G and QSW/QSV82 engines, it is essential to follow proper installation procedures. This includes ensuring that the hose is correctly aligned with the engine’s fluid lines and that all connections are secure and leak-free. Proper installation is crucial to maintaining the engine’s performance and preventing potential issues that could arise from a faulty hose.

The design of the hose allows for easy installation and removal, facilitating maintenance and repairs. This ease of use is a significant advantage, as it reduces downtime and ensures that the engine can be serviced quickly and efficiently.

Performance and Reliability

This part is engineered to provide consistent performance and reliability across a range of operating conditions. Its ability to flex and move without compromising the integrity of the connection ensures that the engine’s fluid systems operate smoothly, without interruptions or failures. This reliability is critical for maintaining the overall health and efficiency of the engine.

Role of Part 3426490 Flexible Hose in Engine Systems

This part is an essential component in various engine systems, facilitating the smooth operation and efficiency of several key assemblies.

Assembly Lubricating Oil

In the assembly lubricating oil system, the flexible hose plays a significant role in transporting lubricating oil to different parts of the engine. This ensures that moving components receive consistent lubrication, reducing friction and wear. The flexibility of the hose allows it to accommodate the dynamic movements and vibrations inherent in engine operation, maintaining a reliable oil flow even under varying conditions.

Oil Assembly Lubricating

Similarly, within the oil assembly lubricating system, the flexible hose is integral to the distribution of oil to critical engine components. It connects various parts of the oil circuit, including the oil pump, filter, and galleries, ensuring that oil is efficiently circulated throughout the engine. This consistent oil flow is vital for maintaining optimal engine performance and longevity.

Plumbing

In the broader context of engine plumbing, the flexible hose is used to connect different subsystems and components. Its flexibility and durability make it ideal for applications where rigid pipes might fail due to engine vibrations or thermal expansion. The hose ensures that fluids, whether lubricants, coolants, or fuels, are reliably transported within the engine system.

Turbocharger

For turbocharged engines, the flexible hose is often employed in the turbocharger oil feed and return lines. Turbochargers require precise lubrication to operate efficiently and withstand high temperatures and pressures. The flexible hose allows for the necessary movement and flexibility in these lines, ensuring that the turbocharger receives a consistent supply of oil, which is essential for its performance and durability.

Conclusion

Overall, the part 3426490 Flexible Hose is a versatile and reliable component that enhances the functionality and efficiency of various engine systems. Its ability to adapt to the dynamic environment within an engine makes it an invaluable part of modern engine design.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.