This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

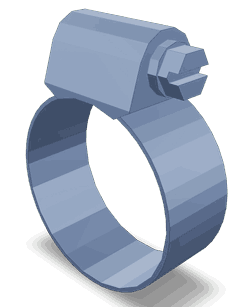

The Hose Clamp 3425609, manufactured by Cummins, is a critical component in the fluid systems of commercial trucks. This part ensures secure connections of hoses to various components, contributing to the efficiency and safety of truck operations. Cummins, a reputable name in the commercial truck industry, designs this clamp for robust performance and reliability.

Basic Concepts of Hose Clamps

Hose clamps are essential in securing hoses to fittings, preventing leaks and maintaining the integrity of fluid systems. They are widely used in automotive, industrial, and commercial applications. Types of hose clamps include worm gear clamps, spring clamps, and screw-type clamps, each designed for specific applications 1.

Purpose of Hose Clamp 3425609

This Cummins part is designed for commercial trucks, securing hoses in fluid systems such as coolant, fuel, and hydraulic systems. It ensures a reliable seal, preventing leaks that could cause system failures or safety hazards 2.

Key Features

Constructed from high-quality materials, the Hose Clamp 3425609 offers durability and long-term performance. Its worm gear mechanism allows for precise adjustment, fitting various hose sizes securely. The clamp is also corrosion-resistant, suitable for harsh environments 3.

Benefits

The durable construction of this part ensures long-term reliability, reducing the need for frequent replacements. Its worm gear design facilitates easy and secure installation. Additionally, its resistance to corrosion and wear contributes to its longevity.

Installation Process

To install the Hose Clamp 3425609, align the hose with the fitting, place the clamp around them, and use the worm gear mechanism to tighten it securely. Avoid over-tightening to prevent hose damage. A wrench is required for adjusting the worm gear.

Troubleshooting Common Issues

Common issues with hose clamps include leaks and improper sealing. Ensure the clamp is correctly installed and tightened. Inspect the hose and fitting for damage if leaks persist. Regular inspections for wear or corrosion can prevent issues.

Maintenance Tips

Regular maintenance of the Hose Clamp 3425609 is crucial for its longevity. Inspect it periodically for wear, corrosion, or damage. Clean the clamp and surrounding areas to prevent debris buildup. Replace the clamp if any signs of wear or failure are detected during routine checks.

Cummins: A Brief Overview

Cummins Inc. is a global leader in designing, manufacturing, and distributing engines, filtration, and power generation products. With over a century of history, Cummins is renowned for producing high-quality, reliable components for commercial vehicles.

Compatibility with Engine Models

The Hose Clamp 3425609 is compatible with several Cummins engine models, including QSV81G, QSV91G, QSW/QSV82, and QSW73. It ensures secure and reliable connections for various fluid and gas lines, maintaining the integrity of the engine’s systems.

Role in Engine Systems

This part is integral to the secure and efficient operation of various engine components. It is used in the Air-Oil Assembly Separator, Crankcase Breather Arrangement, Crankcase Breather, Crankcase Breather Mounting, and Separator Air-Oil Module. The clamp ensures secure connections, preventing leaks and maintaining system integrity.

Conclusion

The Hose Clamp 3425609 by Cummins is a vital component in commercial truck fluid systems. Its robust design, reliable performance, and compatibility with various engine models make it an essential part for maintaining the efficiency and safety of truck operations. Regular maintenance and proper installation are key to ensuring its longevity and effectiveness.

-

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair (2nd ed.). Cengage Learning.

↩ -

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.