This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

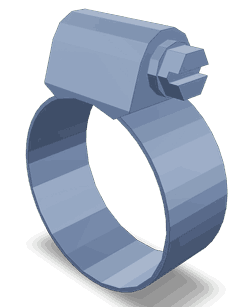

The Hose Clamp 3424940, manufactured by Cummins, is a critical component in the commercial truck industry. This part ensures the integrity of various hose systems within commercial trucks, contributing to efficient and safe operation.

Basic Concepts of Hose Clamps

Hose clamps are essential devices used to secure hoses to fittings, preventing leaks and ensuring a tight seal. They are available in various types, including worm-drive, spring, and screw-type clamps, each designed for specific applications and environments. Hose clamps are vital for maintaining the functionality and safety of fluid transfer systems in vehicles 1.

Purpose of Hose Clamp 3424940

The Hose Clamp 3424940 is designed to secure hoses in various truck systems, including fuel, coolant, and hydraulic lines. Its role is to maintain a secure connection, preventing leaks and ensuring the efficient transfer of fluids under varying conditions. This clamp is particularly useful in environments where vibrations and temperature fluctuations are common 2.

Key Features

The Hose Clamp 3424940 is constructed from high-quality materials, ensuring durability and resistance to corrosion. Its design includes a robust band and a tightening mechanism that allows for precise adjustment, accommodating a range of hose diameters. The clamp’s unique characteristics enhance its performance in demanding applications 3.

Benefits

Using the Hose Clamp 3424940 offers several advantages. Its durable construction ensures long-term reliability, while its design allows for easy installation and adjustment. The clamp’s ability to provide a secure seal contributes to the overall efficiency and safety of the truck’s fluid transfer systems.

Installation Process

Proper installation of the Hose Clamp 3424940 involves several steps. First, ensure the hose and fitting are clean and free of debris. Place the clamp around the hose and fitting, ensuring it is aligned correctly. Use the tightening mechanism to secure the clamp, adjusting until the desired tension is achieved. It is important to avoid over-tightening, which can damage the hose.

Troubleshooting Common Issues

Common issues with hose clamps include leaks and improper sealing. These problems can often be traced back to incorrect installation or wear and tear on the clamp. Solutions may involve re-tightening the clamp, replacing worn components, or ensuring the clamp is the correct size for the hose and fitting.

Maintenance Tips

Regular maintenance of hose clamps is crucial for ensuring longevity and optimal performance. This includes periodic inspections for signs of wear or corrosion, and replacement of clamps that show signs of damage. Adhering to manufacturer-recommended inspection schedules can help prevent unexpected failures.

Safety Considerations

When working with hose clamps, it is important to follow safety practices to prevent injuries and equipment damage. This includes ensuring proper installation to avoid leaks, conducting regular checks for wear or damage, and using the correct tools and techniques during installation and maintenance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry, offering a wide range of products designed to meet the demands of modern transportation.

Cummins Hose Clamp 3424940 Compatibility with QSV Engines

The Cummins Hose Clamp part number 3424940 is designed to fit seamlessly with a variety of QSV engines, including the QSV81G and QSV91G models. This part is integral for maintaining the integrity of hose connections, ensuring that there are no leaks or disconnections that could compromise engine performance.

For the QSV81G and QSV91G engines, the hose clamp 3424940 is engineered to provide a secure fit around hoses that connect to critical engine components. This ensures that the hoses remain firmly in place under varying operational conditions, including high temperatures and pressures.

The compatibility of this hose clamp with these engines is a testament to Cummins’ commitment to providing reliable and durable parts that meet the stringent demands of heavy-duty engine applications. By using the 3424940 hose clamp, engine operators can have confidence in the reliability and longevity of their engine’s hose connections.

Role of Part 3424940 Hose Clamp in Engine Systems

The part 3424940 Hose Clamp is an essential component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain a tight seal around hoses that connect different parts of the engine, preventing leaks and ensuring that fluids and gases are properly channeled.

In the Air Fuel Assembly Mixer and Assembly Mixer Air Fuel, the Hose Clamp ensures that the air and fuel mixture is delivered consistently without any interruptions. This is vital for the combustion process, as any leak could result in an imbalanced mixture, affecting engine performance.

For the Filter Assembly Shell and Filter Shell and Gas Mixers, the Hose Clamp plays a role in keeping the filtration process efficient. By securing the hoses that connect these components, it ensures that contaminants are effectively filtered out before the mixture reaches the combustion chamber.

In systems like the Gas Module P=1, 25bar and Gas Module P=1, 8bar, the Hose Clamp is responsible for maintaining the integrity of the gas delivery system. These modules operate under specific pressure conditions, and any leak could lead to a drop in pressure, affecting the module’s performance.

The Low BTU Fuel Module V16 and Low BTU Fuel Module V18 also benefit from the secure connections provided by the Hose Clamp. These modules require precise fuel delivery to function correctly, and any leakage could result in inefficient fuel usage and reduced engine efficiency.

Additionally, in the Module Fuel Control and Module Gas, the Hose Clamp ensures that the control signals and gas flows are accurately transmitted. This is important for the overall regulation and management of the engine’s fuel and gas systems.

Finally, in the Module P=3bar Gas system, the Hose Clamp helps maintain the high-pressure gas delivery required for optimal engine operation. Secure connections are paramount in this system to prevent any pressure loss that could compromise engine performance.

Conclusion

The Hose Clamp 3424940 by Cummins is a vital component in maintaining the integrity and efficiency of various hose systems in commercial trucks. Its durable construction, precise adjustment capabilities, and compatibility with QSV engines make it an indispensable part for ensuring secure and leak-free connections in demanding environments.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.