This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3408224 Flexible Hose is a component designed for use in commercial trucks. It serves as a conduit for various fluids within the truck’s systems, facilitating the transfer of these fluids between different parts of the vehicle. Its application is essential for maintaining the operational integrity of the truck’s systems, ensuring efficient and reliable performance.

Basic Concepts of Flexible Hoses

Flexible hoses are utilized in automotive applications to connect different parts of a system that may move or vibrate relative to each other. They are designed to accommodate movement and provide a secure, leak-free connection. Within a system, flexible hoses allow for the transfer of fluids such as coolant, fuel, or hydraulic fluid, contributing to the overall functionality and efficiency of the vehicle 1.

Purpose of the 3408224 Flexible Hose

This Cummins part plays a specific role in the operation of a truck by connecting various systems and transporting fluids. It is typically used in applications where flexibility and durability are required, such as in the fuel system, where it may connect the fuel tank to the engine or other components. The hose is designed to withstand the pressures and temperatures associated with these fluids, ensuring a reliable connection 2.

Key Features

The 3408224 Flexible Hose is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that provide resistance to wear, tear, and environmental factors. The design includes reinforced layers to withstand pressure and maintain shape, as well as smooth inner and outer surfaces to facilitate fluid flow and reduce the risk of kinking. Additionally, the hose may feature specialized fittings or connectors to ensure a secure attachment to the systems it serves 3.

Benefits

Utilizing this Cummins part offers several advantages. Its flexibility allows for greater movement and vibration absorption compared to rigid hoses, reducing the risk of damage or disconnection. The hose’s resistance to wear and tear contributes to its longevity, potentially reducing the need for frequent replacements. Furthermore, its design may lead to reduced maintenance requirements, as it is less prone to issues such as leaks or kinks.

Installation Considerations

Proper installation of the 3408224 Flexible Hose is vital to ensure a secure and effective fit. It is recommended to follow manufacturer guidelines for installation, which may include specific tools or procedures. Ensuring the hose is correctly aligned and tightened can prevent leaks and maintain the integrity of the system it serves. Additionally, inspecting the hose for any signs of damage before installation can help avoid future issues.

Troubleshooting Common Issues

Common problems with flexible hoses, such as leaks or kinks, can often be traced back to installation errors or wear and tear. Diagnosing these issues involves a thorough inspection of the hose and its connections. Addressing leaks may require tightening connections or replacing damaged sections, while kinks can sometimes be resolved by repositioning the hose or replacing it if the damage is severe.

Maintenance Tips

Regular maintenance of the 3408224 Flexible Hose can prolong its life and ensure continued reliable performance. This includes periodic inspections for signs of wear, such as cracks or softening of the material, and checking connections for tightness. Cleaning the hose and its surroundings can also prevent the accumulation of debris that may contribute to wear or obstruction of fluid flow.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins has established itself as a trusted name in the commercial truck industry. The company’s focus on developing reliable and efficient components, such as the 3408224 Flexible Hose, underscores its dedication to enhancing the performance and durability of commercial vehicles.

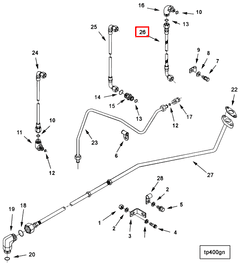

Role of Part 3408224 Flexible Hose in Plumbing and Turbocharger Systems

Plumbing Systems

In plumbing systems, the 3408224 Flexible Hose serves as a vital connector between various components, facilitating the transfer of fluids such as water, gas, or oil. Its flexibility allows it to accommodate the movements and vibrations inherent in plumbing setups, reducing the risk of leaks and ensuring a secure connection. This hose is often used to link pipes to appliances, valves, and meters, providing a durable and reliable solution for fluid transport. Its ability to withstand pressure fluctuations and environmental conditions makes it an essential component in maintaining the integrity and efficiency of plumbing networks 4.

Turbocharger Systems

Within turbocharger systems, the 3408224 Flexible Hose plays a significant role in managing the flow of exhaust gases and coolant. It connects the turbocharger to the engine and other components, allowing for the efficient transfer of high-temperature exhaust gases that drive the turbine. Additionally, it is used in coolant systems to maintain optimal operating temperatures by circulating coolant between the turbocharger and the engine. The hose’s flexibility is particularly beneficial in this application, as it can absorb the vibrations and movements generated by the turbocharger, ensuring a stable and leak-free connection. This contributes to the overall performance and longevity of the turbocharger system.

Conclusion

The Cummins 3408224 Flexible Hose is a critical component in the operation of commercial trucks, offering flexibility, durability, and reliable fluid transfer across various systems. Proper installation, regular maintenance, and understanding its role in different applications can enhance the performance and longevity of the vehicle’s systems.

-

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.