This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

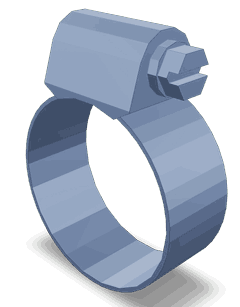

The Cummins 3396092 Hose Clamp Fastener is a critical component in commercial trucks, designed to secure hoses within various vehicle systems. This ensures tight and sealed connections, preventing leaks and maintaining proper fluid flow, which is essential for the efficiency and reliability of the truck’s operations 3.

Basic Concepts of Hose Clamp Fasteners

Hose clamp fasteners are essential in automotive applications for creating secure connections between hoses and fittings. They apply even pressure around the hose to compress it against the fitting, forming a seal. This is vital for maintaining the integrity of fluid systems, including fuel, coolant, and hydraulic lines, ensuring hoses remain firmly attached under various operating conditions 1.

Purpose of the 3396092 Hose Clamp Fastener

The 3396092 Hose Clamp Fastener is specifically engineered for commercial truck applications. It is used in various hose systems, including engine cooling, fuel delivery, and hydraulic operations. By providing a reliable seal, this fastener helps maintain the performance and safety of the truck’s systems 3.

Key Features

The 3396092 Hose Clamp Fastener is constructed from durable materials, ensuring longevity and resistance to wear. Its design allows for easy installation and adjustment, facilitating a secure fit without specialized tools. Additionally, it is engineered to withstand environmental factors such as temperature fluctuations and chemical exposure, ensuring consistent performance over time 2.

Benefits

Using the 3396092 Hose Clamp Fastener offers several benefits. It provides improved seal integrity, reducing the risk of leaks in critical systems. The design allows for ease of installation, saving time during maintenance procedures. Its durability ensures long-term performance, and its resistance to environmental factors makes it suitable for various operating conditions 3.

Installation Process

Installing the 3396092 Hose Clamp Fastener involves positioning the clamp over the hose and fitting, then using appropriate tools to tighten it gradually, ensuring even pressure is applied around the hose. It is important to follow manufacturer guidelines for torque settings to avoid over-tightening, which can damage the hose or fitting. Regular checks should be performed to ensure the clamp remains secure over time 1.

Troubleshooting Common Issues

Common issues with hose clamp fasteners include leaks due to improper installation or wear over time. To address these problems, ensure the clamp is correctly positioned and tightened according to specifications. If leaks persist, inspect the hose and fitting for damage. Replacement of worn components may be necessary to restore system integrity 2.

Maintenance Tips

Regular maintenance of the 3396092 Hose Clamp Fastener is crucial for ensuring long-term performance. Inspect the clamp and hose connections during routine maintenance checks. Look for signs of wear, corrosion, or leaks. Replace the fastener if it shows signs of damage or if the hose needs to be replaced. Adhering to recommended inspection intervals will help maintain the reliability of the truck’s systems 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality and innovation in the automotive industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ dedication to excellence is evident in its rigorous testing and quality control processes, ensuring that its products deliver reliable performance and durability 3.

Cummins Hose Clamp Fastener 3396092 Compatibility

The Cummins Hose Clamp Fastener part number 3396092 is designed to be compatible with a variety of engine models. This part is essential for securing hoses and ensuring a tight seal, which is crucial for maintaining engine performance and preventing leaks.

Compatible Engines

- G5.9

- G8.3

- G855

- G855 CM558

- GTA855 CM558 (CM2358) G101

- ISC CM850

- ISL9 CM2150 SN

- N14 G

These engines, while differing in specifications and applications, share a commonality in their use of the 3396092 Hose Clamp Fastener. This part ensures that hoses are properly fastened, which is vital for the integrity of the engine’s cooling, fuel, and exhaust systems.

By using the 3396092 Hose Clamp Fastener, technicians and operators can be confident that their engines will maintain optimal performance and reliability 3.

Understanding the Role of Part 3396092 Hose Clamp Fastener in Engine Systems

The Hose Clamp Fastener, identified by part number 3396092, is a critical component in ensuring the secure attachment of hoses within various engine systems. Its application spans across multiple critical areas, contributing to the overall efficiency and reliability of the engine.

Breather and Crankcase Systems

In breather and crankcase systems, the Hose Clamp Fastener is utilized to maintain a tight seal on hoses that facilitate the circulation of gases and fluids. This ensures that the crankcase ventilation system operates effectively, allowing for the proper release of pressure and the removal of contaminants from the crankcase.

Water Outlet and Heat Exchanger Connections

At the water outlet, the Hose Clamp Fastener secures hoses that connect to the heat exchanger. This connection is vital for the efficient transfer of heat between the engine coolant and the surrounding air, aiding in the regulation of engine temperature.

Manifold and Exhaust Systems

Within the manifold and exhaust systems, the Hose Clamp Fastener plays a role in securing hoses that are part of the emissions control system. This includes connections to the Exhaust Gas Recirculation (EGR) valve and other components that help reduce emissions and improve engine performance.

Engine Control and Fuel Control Modules

In the context of engine control and fuel control modules, the Hose Clamp Fastener is used to secure hoses that supply fluids or gases to sensors and actuators. This ensures accurate readings and efficient operation of the engine control systems.

Resistor and Corrosion Protection

The Hose Clamp Fastener also finds its application in systems where resistors are used to manage electrical flow. Additionally, it is employed in areas prone to corrosion, such as connections to the expansion tank, to ensure that hoses remain securely attached despite exposure to corrosive elements.

Turbocharger Plumbing

In turbocharger systems, the Hose Clamp Fastener is crucial for securing hoses that carry pressurized air or fluids. This ensures that the turbocharger operates within its designed parameters, contributing to enhanced engine performance and efficiency.

Overall, the Hose Clamp Fastener (part 3396092) is a versatile component that plays a significant role in maintaining the integrity and functionality of various engine systems. Its application across different components underscores its importance in ensuring the smooth operation of the engine 3.

Conclusion

The Cummins 3396092 Hose Clamp Fastener is a vital component in commercial trucks, ensuring secure and reliable hose connections across various engine systems. Its durable construction, ease of installation, and resistance to environmental factors make it an essential part for maintaining the efficiency and reliability of truck operations. Regular maintenance and proper installation are key to maximizing the performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.