This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

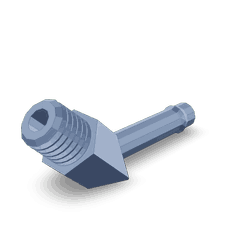

The 3286617 Elbow Hose Coupling by Cummins is a specialized component designed for use in commercial trucks. This part facilitates the connection between hoses and other fluid system components, ensuring efficient and reliable fluid transfer. Its role in the operation of commercial trucks is significant, as it contributes to the overall functionality and performance of the vehicle’s fluid systems.

Basic Concepts of Elbow Hose Couplings

An elbow hose coupling is a fitting used to join two hoses at an angle, typically 90 degrees, within a fluid system. It allows for the redirection of fluid flow without the need for additional bends or fittings, which can reduce system complexity and improve efficiency. In automotive and industrial settings, elbow hose couplings are employed in various applications, including fuel, coolant, and hydraulic systems, to facilitate fluid transfer and maintain system integrity 1.

Purpose of the 3286617 Elbow Hose Coupling

This Cummins part is designed to play a specific role in the operation of a truck’s fluid systems. It provides a secure and efficient connection between hoses, allowing for the smooth transfer of fluids such as coolant, fuel, or hydraulic fluid. This coupling ensures that the fluid systems within the truck operate effectively, contributing to the vehicle’s overall performance and reliability.

Key Features

The 3286617 Elbow Hose Coupling boasts several key features that enhance its performance and durability. These include a robust material composition, typically consisting of high-quality metals or durable polymers, which ensures resistance to corrosion and wear. The design of the coupling incorporates precise machining and tight tolerances to provide a secure fit and minimize the risk of leaks. Additionally, the coupling may feature unique attributes such as integrated seals or gaskets to further enhance its performance and reliability.

Benefits

The 3286617 Elbow Hose Coupling offers several benefits that contribute to its effectiveness in commercial truck applications. These include improved fluid flow due to its efficient design, reduced leakage thanks to its secure fitting and integrated seals, enhanced durability resulting from its high-quality materials and construction, and ease of installation, which allows for quick and straightforward replacement or maintenance.

Installation Process

Proper installation of the 3286617 Elbow Hose Coupling is crucial to ensure a secure and efficient connection. The process typically involves the following steps: First, ensure that the hoses to be connected are clean and free of debris. Next, align the coupling with the hoses and insert it into place, ensuring a snug fit. Use the appropriate tools, such as wrenches or pliers, to tighten the coupling securely without over-tightening, which could damage the fitting or the hoses. Finally, inspect the connection for any signs of leakage or improper fitting, and make adjustments as necessary.

Troubleshooting Common Issues

Common problems associated with elbow hose couplings, such as leaks or improper fitting, can often be addressed through careful troubleshooting. If a leak is detected, first ensure that the coupling is properly installed and tightened. If the issue persists, inspect the hoses for damage or wear, and replace them if necessary. Additionally, check for any signs of corrosion or debris within the coupling, and clean or replace it as needed to restore proper function.

Maintenance Tips

Regular maintenance of the 3286617 Elbow Hose Coupling is important to ensure long-term performance and reliability. This includes periodic inspection of the coupling for signs of wear, corrosion, or damage, and cleaning it as necessary to remove any debris or buildup. Additionally, following the manufacturer’s recommended inspection intervals and adhering to proper installation and maintenance procedures will help to prolong the life of the coupling and ensure optimal performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial truck applications. Cummins’ dedication to excellence is evident in its continued investment in research and development, as well as its focus on sustainability and environmental responsibility 2.

Engine Compatibility for Elbow Hose Coupling Part 3286617

The Elbow Hose Coupling part number 3286617, manufactured by Cummins, is a critical component in the engine’s cooling and exhaust systems. This part is designed to ensure a secure and leak-proof connection between hoses and engine components, facilitating the efficient flow of fluids and gases.

Compatibility with 6C8.3 Engines

The 6C8.3 engine, known for its robust performance and reliability, integrates the Elbow Hose Coupling part 3286617 in several key areas. This part is essential for maintaining the integrity of the engine’s cooling system, ensuring that coolant flows smoothly and efficiently. Additionally, it plays a role in the exhaust system, helping to manage the flow of exhaust gases and reduce back pressure, which can enhance engine performance and efficiency.

Grouping of Compatible Engines

While the primary focus here is on the 6C8.3 engine, it is important to note that the Elbow Hose Coupling part 3286617 is also compatible with other Cummins engines within the same engine family. These engines share similar design principles and system configurations, making the part interchangeable across different models. This compatibility ensures that maintenance and repair tasks can be performed with ease, using a standardized part across multiple engine types.

Role of Part 3286617 Elbow Hose Coupling in Engine Systems

The 3286617 Elbow Hose Coupling is an essential component in the fluid dynamics of engine systems, specifically within the radiator and engine coolant pathways. It facilitates the secure and efficient connection between hoses that transport engine coolant, ensuring a seamless flow from the radiator to the engine and back.

In the context of the radiator, the Elbow Hose Coupling is positioned at strategic points where the coolant hoses need to change direction. This allows the coolant to navigate the complex layout of the engine compartment without compromising the integrity of the hose connections. The coupling’s design accommodates the necessary angles and bends, maintaining a consistent coolant flow which is vital for effective heat dissipation.

When considering the vent system, the Elbow Hose Coupling plays a role in managing the pressure within the coolant system. By providing a reliable connection point, it helps in maintaining the system’s pressure balance, which is important for the proper function of the vent and the overall cooling efficiency.

In the engine coolant circuit, the coupling ensures that the coolant is distributed evenly throughout the engine block and cylinder heads. This uniform distribution is key to preventing hotspots and ensuring that all components of the engine receive adequate cooling. The Elbow Hose Coupling’s robust construction and precise fit contribute to the longevity and reliability of the coolant system, supporting the engine’s performance and durability 3.

Conclusion

The 3286617 Elbow Hose Coupling by Cummins is a vital component in the fluid systems of commercial trucks, ensuring efficient and reliable fluid transfer. Its robust design, key features, and benefits contribute to the overall performance and reliability of the vehicle. Proper installation, maintenance, and troubleshooting are essential to maximize the effectiveness of this part in engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.