This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3093543 Hose Nipple is a component designed for use in commercial trucks, manufactured by Cummins Inc., a well-established name in the automotive and engine manufacturing industry. Hose nipples play a significant role in fluid transfer systems by providing secure and leak-free connections between hoses and other components. This Cummins part is specifically engineered to meet the demanding requirements of commercial truck operations, ensuring reliable fluid transfer in various systems 1.

Basic Concepts of Hose Nipples

A hose nipple is a short pipe fitting with a male threaded end used to connect hoses to other components in fluid systems. Its general function is to facilitate secure connections that prevent leaks and ensure the efficient transfer of fluids. Hose nipples can connect to various types of fittings, including female threaded ports, barb fittings, and quick-connect couplings. They play a role in maintaining the integrity of fluid systems by providing a reliable interface between flexible hoses and rigid pipes or components 2.

Purpose of the 3093543 Hose Nipple in Truck Operations

This part is designed to play a specific role in the operation of commercial trucks by connecting various systems and handling different fluids such as coolant, fuel, or hydraulic fluid. It ensures that these fluids are transferred efficiently and securely throughout the truck’s systems, contributing to the overall performance and reliability of the vehicle. By providing a stable connection point, the hose nipple helps maintain the pressure and flow rates necessary for optimal system operation 3.

Key Features of the 3093543 Hose Nipple

The design and construction of the 3093543 Hose Nipple include several features that enhance its performance and durability. It is made from high-quality materials that resist corrosion and wear, ensuring long-term reliability. The thread type and connection specifications are tailored to fit specific applications, providing a secure and leak-free joint. These features contribute to the hose nipple’s ability to withstand the rigors of commercial truck operations.

Benefits of Using the 3093543 Hose Nipple

The 3093543 Hose Nipple offers several advantages in fluid transfer operations. It contributes to improved system efficiency by ensuring secure and leak-free connections. This reduces the need for frequent maintenance and repairs, leading to lower overall costs. Additionally, the reliable performance of the hose nipple enhances safety by preventing fluid leaks that could pose a hazard during operation.

Installation Considerations

Proper installation of the 3093543 Hose Nipple is important to ensure its effective performance. Guidelines for installation include adhering to torque specifications to avoid over-tightening, which can damage the threads, or under-tightening, which can lead to leaks. Alignment procedures should be followed to ensure that the hose nipple is properly positioned relative to the connected components. Compatibility with other system components must also be considered to ensure a secure and functional connection.

Troubleshooting Common Issues

Common problems associated with hose nipples, such as leaks or connection failures, can often be traced to installation errors or wear and tear. Troubleshooting steps may include checking for proper torque, ensuring correct alignment, and inspecting for signs of corrosion or damage. Addressing these issues promptly can help maintain the integrity of the fluid transfer system and prevent more serious problems down the line.

Maintenance Tips

Regular maintenance of the 3093543 Hose Nipple is important to ensure long-term reliability and performance. Inspection intervals should be established to check for signs of wear, corrosion, or damage. Cleaning procedures may be necessary to remove buildup that could affect the connection’s integrity. Knowing when to consider replacement is also important, as worn or damaged hose nipples can compromise system performance and safety.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality and innovation in the automotive and engine manufacturing industry. The company’s product range includes a variety of components and systems designed to meet the needs of commercial vehicles, industrial equipment, and power generation applications. Cummins’ commitment to excellence is reflected in the performance and reliability of its products, including the 3093543 Hose Nipple 4.

Compatibility with QST30 Engines

The 3093543 Hose Nipple is designed to fit seamlessly with various QST30 engine models. This part is crucial for maintaining the integrity of the engine’s cooling and fuel systems by ensuring secure connections for hoses.

QST30 CM2350 T101 and QST30 CM552

For the QST30 CM2350 T101 and QST30 CM552 engines, the 3093543 is engineered to integrate with the engine’s design specifications. This compatibility ensures that the hose connections remain leak-proof and durable under the operational conditions these engines typically encounter. The precision in the design of this part guarantees that it will fit snugly and function effectively, contributing to the overall reliability and performance of the engines.

Ensuring Engine Performance

The 3093543 is a critical component in the engine’s assembly, providing a reliable connection point for hoses that transport essential fluids. Its compatibility with the QST30 CM2350 T101 and QST30 CM552 engines underscores its importance in maintaining the engine’s operational efficiency and longevity.

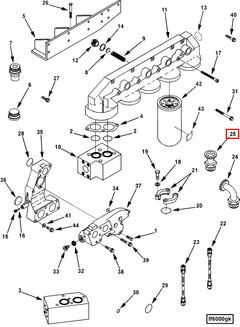

Role of Part 3093543 Hose Nipple in Engine Systems

The 3093543 Hose Nipple is integral to the efficient operation of various engine systems, particularly in the context of fluid management and filtration processes.

In the full flow oil filtration system, the Hose Nipple facilitates the connection between the oil filter and other components of the system. This ensures a secure and leak-free pathway for the oil to travel from the engine to the filter, where contaminants are removed before the oil is recirculated. The reliability of this connection is essential for maintaining the cleanliness of the lubricating oil, which in turn protects engine components from wear and tear.

Similarly, within the lubricating oil system, the Hose Nipple plays a significant role in maintaining the integrity of the oil flow. It connects the oil pump to the filter and other critical components, ensuring that the lubricating oil is distributed evenly throughout the engine. This consistent flow is vital for reducing friction between moving parts, cooling the engine, and carrying away debris.

Overall, the Hose Nipple is a fundamental component that supports the seamless operation of these systems, contributing to the overall efficiency and longevity of the engine.

Conclusion

The 3093543 Hose Nipple by Cummins is a vital component in the fluid transfer systems of commercial trucks and engines. Its design and features ensure secure, leak-free connections that contribute to the efficiency, reliability, and safety of the systems it serves. Proper installation, maintenance, and troubleshooting are essential to maximize the performance and longevity of this part, ultimately supporting the overall operation and durability of the vehicles and engines it is part of.

-

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ -

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ -

Kluczyk, B. (2008). How to Rebuild Any Automotive Engine. CarTech.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659865.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.