This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3093542 Hose Nipple is a component designed for use in commercial truck operations. It serves a specific function within the truck’s fluid systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is important for maintaining and optimizing truck performance.

Basic Concepts of Hose Nipples

A hose nipple is a short pipe fitting with an external thread on one end and a smooth bore through the center. It is used to connect hoses to various components within fluid systems. In the context of a truck, hose nipples facilitate the transfer of fluids such as fuel, coolant, and hydraulic fluid between different parts of the system. They ensure a secure and leak-free connection, which is vital for the proper operation of the truck’s subsystems 1.

Purpose of the 3093542 Hose Nipple

The 3093542 Hose Nipple plays a role in the fluid transfer systems of a truck by providing a connection point for hoses. It is specifically designed to interface with other components, ensuring that fluids are transferred efficiently and without leakage. This part is integral to maintaining the integrity of the fluid pathways within the truck 2.

Key Features

The 3093542 Hose Nipple is constructed from materials that offer durability and resistance to the corrosive effects of various fluids. It features a specific thread type that ensures a secure fit with compatible components. The connection specifications are designed to accommodate standard hose sizes, facilitating easy integration into existing systems 3.

Benefits

Using the 3093542 Hose Nipple can lead to improved efficiency within the fluid systems of a truck. Its durable construction contributes to the longevity of the component, reducing the need for frequent replacements. Additionally, the design of the nipple allows for straightforward installation, which can save time during maintenance procedures 4.

Installation Process

To install the 3093542 Hose Nipple, begin by ensuring that the connection point is clean and free of debris. Thread the nipple into the appropriate fitting by hand to avoid cross-threading. Once hand-tight, use a wrench to secure the connection, being careful not to overtighten, which could damage the threads. Verify the connection for leaks before operating the system.

Troubleshooting and Maintenance

Common issues with hose nipples include leaks, thread damage, and corrosion. To troubleshoot, inspect the connections for signs of wear or damage. If a leak is detected, tighten the connection or replace the nipple if necessary. Regularly check for corrosion and clean the nipple as needed to prevent buildup that could lead to failure.

Compatibility and Usage

The 3093542 Hose Nipple is designed for use in various truck models and fluid systems. It is compatible with standard hose sizes and thread types commonly found in commercial trucks. Its application is widespread across different makes and models, making it a versatile component for fleet maintenance.

Safety Considerations

When installing or maintaining the 3093542 Hose Nipple, it is important to adhere to safety protocols. This includes observing pressure ratings to prevent overpressurization, which could lead to component failure. Environmental factors such as temperature and exposure to chemicals should also be considered to ensure the nipple’s material remains intact and functional.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation, Cummins serves the automotive and heavy-duty truck industries, among others. The company is committed to advancing technology and providing reliable components that contribute to the efficiency and performance of vehicles worldwide.

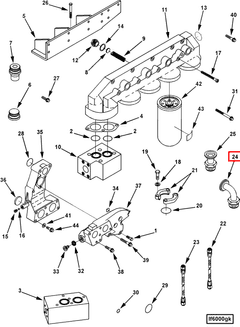

Cummins Engine Compatibility with Hose Nipple Part 3093542

The Hose Nipple part 3093542, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is crucial for maintaining the integrity of the engine’s fluid systems, ensuring that connections are secure and leak-free.

QST30 CM2350 T101 and QST30 CM552

The Hose Nipple part 3093542 is compatible with both the QST30 CM2350 T101 and QST30 CM552 engines. These engines are part of Cummins’ QST30 series, which is known for its robust performance and reliability in various industrial applications. The part’s design ensures a precise fit, facilitating easy installation and maintenance.

Engine Group Compatibility

The Hose Nipple part 3093542 is engineered to fit within the broader QST30 engine group. This compatibility extends to other models within the same series, ensuring that technicians and maintenance personnel can use this part across multiple engine types without the need for specialized fittings or modifications.

Installation Considerations

When installing the Hose Nipple part 3093542, it is essential to follow the manufacturer’s guidelines to ensure a secure and leak-proof connection. Proper installation is critical for maintaining the engine’s performance and longevity, as any leaks can lead to significant operational issues.

Maintenance and Replacement

Regular inspection of the Hose Nipple part 3093542 is recommended to ensure it remains in good condition. Over time, wear and tear can compromise the seal, leading to potential leaks. Replacing the part with an authentic Cummins component is advised to maintain the engine’s efficiency and reliability.

Role of Part 3093542 Hose Nipple in Engine Systems

The 3093542 Hose Nipple is an essential component in the fluid management systems of various engine setups. It facilitates the secure connection between hoses and other components, ensuring efficient fluid transfer.

Integration with Filters

In systems utilizing filters, such as full flow oil filters and lubricating oil filters, the 3093542 Hose Nipple plays a significant role. It connects the filter housing to the hoses that transport oil to and from the filter. This connection ensures that oil flows smoothly through the filter media, where contaminants are trapped, resulting in cleaner oil circulating within the engine. The secure fit provided by the Hose Nipple prevents leaks, maintaining system integrity and efficiency.

Application in Full Flow Oil Systems

Within full flow oil systems, the 3093542 Hose Nipple is employed to link the oil pump to the filter and subsequently to the engine’s lubrication points. This setup ensures that the oil, after being filtered, is distributed evenly throughout the engine, reducing wear and tear on moving parts. The Hose Nipple’s design allows for easy maintenance and replacement, facilitating efficient system upkeep.

Use in Lubricating Oil Circuits

In lubricating oil circuits, the 3093542 Hose Nipple is integral to maintaining the proper flow of lubricating oil. It connects various components such as the oil reservoir, pump, and distribution lines. This ensures that all engine components receive adequate lubrication, enhancing performance and longevity. The Hose Nipple’s robust construction withstands the pressures and temperatures within the lubricating system, providing reliable service over time.

Conclusion

Overall, the 3093542 Hose Nipple is a vital component in ensuring the smooth operation of engine fluid systems, contributing to the overall efficiency and reliability of the engine.

-

Reif, Konrad. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩ -

Robinson, Alan and Livesey, Andrew. The Repair of Vehicle Bodies Fifth Edition. Elsevier, 2006.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.