This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

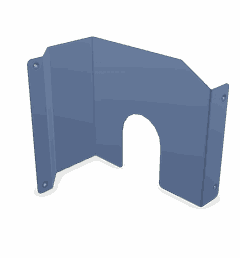

The Cummins 3978806 Heat Shielding is a component designed to manage and mitigate the effects of heat in heavy-duty truck applications. Its purpose is to protect various truck components from excessive heat, thereby contributing to the overall efficiency and longevity of the vehicle. Understanding its function and significance is vital for maintaining the performance and safety of heavy-duty trucks.

Basic Concepts of Heat Shielding

Heat shielding refers to materials and designs used to protect components from high temperatures. These shields work by reflecting or absorbing heat, preventing it from affecting nearby parts. In the context of heavy-duty trucks, heat shielding is crucial for protecting sensitive components from the intense heat generated by the engine and exhaust system. This protection helps maintain the integrity and performance of these components, ensuring the truck operates efficiently and safely 1.

Purpose of Cummins 3978806 Heat Shielding

The Cummins 3978806 Heat Shielding is specifically designed to protect certain components within a truck’s engine compartment from excessive heat. It is used in environments where high temperatures are common, such as near the exhaust system or other heat-generating parts. By shielding these components, it helps maintain their structural integrity and operational efficiency, contributing to the overall performance of the truck.

Key Features

The Cummins 3978806 Heat Shielding boasts several key features that enhance its performance. It is made from high-quality materials that offer excellent heat resistance. The design includes precise engineering to ensure it fits snugly around the components it protects, maximizing its effectiveness. Additionally, it may feature unique characteristics such as a reflective surface to better manage heat distribution.

Benefits

The use of the Cummins 3978806 Heat Shielding offers several benefits. It contributes to the improved durability of protected components by reducing the impact of heat. This, in turn, can lead to enhanced safety, as components are less likely to fail due to heat-related issues. Furthermore, by maintaining the efficiency of these components, the overall operational efficiency of the truck may be increased 2.

Installation Considerations

When installing the Cummins 3978806 Heat Shielding, it is important to follow guidelines and best practices to ensure optimal performance. Preparatory steps may include cleaning the area where the shield will be installed and ensuring all components are free from debris. The necessary tools for installation should be gathered beforehand. Common pitfalls to avoid include improper fitting, which can reduce the effectiveness of the shield, and not securing it properly, which could lead to it becoming dislodged during operation.

Troubleshooting and Maintenance

To troubleshoot common issues related to the Cummins 3978806 Heat Shielding, regular inspections are recommended. Look for signs of wear or damage, such as cracks or warping, which may indicate the need for replacement. Maintenance tips include keeping the shield clean and free from debris, as accumulation can affect its performance. Regular checks ensure the shield continues to provide the intended protection.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industries. Its product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of vehicles 3.

Cummins Heat Shielding Part 3978806

The Cummins Heat Shielding part 3978806 is designed to fit seamlessly with various Cummins engines, ensuring optimal thermal management and protection. This heat shielding component is engineered to withstand high temperatures and reduce heat transfer, thereby enhancing the engine’s efficiency and longevity.

K50 Engines

For the K50 engine series, the heat shielding part 3978806 is specifically tailored to fit around critical engine components. Its placement is crucial in protecting sensitive parts from excessive heat, which can lead to performance degradation and potential damage. The design ensures that the heat shield effectively minimizes heat exposure while maintaining the structural integrity of the engine.

Integration with Cummins Engines

The integration of the heat shielding part 3978806 into Cummins engines is a meticulous process. It involves precise alignment and secure attachment to prevent any movement or misalignment during operation. This ensures that the heat shield remains effective in its role, providing consistent protection across various engine conditions.

The part is made from high-quality materials that can endure the harsh operating environments of Cummins engines. Its robust construction guarantees durability and reliability, making it an essential component for maintaining engine performance and safety.

Role of Part 3978806 Heat Shielding in Engine Systems

Part 3978806 Heat Shielding is integral to the efficient and safe operation of various engine systems. Its primary function is to manage and mitigate the extreme temperatures generated by the engine, ensuring the longevity and reliability of surrounding components.

Exhaust System Protection

In the exhaust system, the heat shielding provided by part 3978806 is essential for protecting adjacent components from the high temperatures produced during combustion. This includes safeguarding the exhaust manifold, catalytic converter, and exhaust pipes. By reducing heat transfer, the shielding helps maintain the structural integrity of these parts, preventing warping and degradation over time.

Engine Bay Insulation

Within the engine bay, the heat shielding plays a significant role in maintaining a controlled thermal environment. It protects sensitive electronic components, such as the engine control unit (ECU) and wiring harnesses, from heat damage. Additionally, it shields plastic and rubber components, which are particularly vulnerable to heat-induced degradation, ensuring they remain functional and durable.

Turbocharger and Intercooler Support

For turbocharged engines, the heat shielding is vital in managing the temperatures around the turbocharger and intercooler. It helps in maintaining optimal operating temperatures for these components, enhancing performance and efficiency. By reducing heat soak, the shielding ensures that the turbocharger and intercooler can function effectively, contributing to better overall engine performance.

Fuel System Integrity

The fuel system, including the fuel lines and injectors, benefits from the heat shielding as well. By keeping these components at a stable temperature, the shielding helps prevent fuel degradation and ensures consistent fuel delivery. This is particularly important in high-performance engines where fuel efficiency and reliability are paramount.

Undercarriage and Chassis Protection

Part 3978806 also extends its protective capabilities to the undercarriage and chassis of the vehicle. By shielding these areas from excessive heat, it helps in preserving the structural integrity of the chassis and preventing heat-related damage to undercarriage components. This is especially important in off-road or high-stress driving conditions where the undercarriage is exposed to additional heat sources.

Conclusion

In summary, the heat shielding provided by part 3978806 is a multifaceted component that enhances the performance, durability, and safety of various engine systems. Its role in temperature management is indispensable for the optimal functioning of both mechanical and electronic components within the engine environment.

-

Haoran Hu, Rudy Smaling, Simon Baseley, Heavy-Duty Wheeled Vehicles, SAE International, 2014.

↩ -

Tigran Parikyan Ed, Advances in Engine and Powertrain Research and Technology, Springer Nature, 2022.

↩ -

Willard W. Pulkrabek, Engineering Fundamentals of the Internal Combustion Engine, Pearson Education, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.