This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

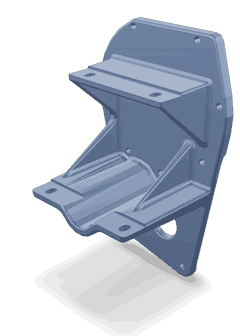

The Cummins Heat Exchanger Bracket, part number 4058110, is a component designed for commercial truck operations. Cummins, a prominent name in the industry, manufactures a range of parts and systems that enhance the efficiency and reliability of commercial vehicles. This Cummins part is integral to the cooling systems of trucks, contributing to their operational efficiency and reliability.

Basic Concepts of Heat Exchanger Brackets

A heat exchanger bracket serves as a mounting component for heat exchangers within a truck’s cooling system. Its primary function is to secure the heat exchanger, ensuring stability and proper alignment with other system components. This bracket facilitates heat transfer between the engine’s coolant and the ambient air, aiding in engine temperature regulation. It interfaces with various parts of the cooling system, including hoses, pipes, and the heat exchanger itself, ensuring a cohesive and efficient cooling process 1.

Purpose of the Heat Exchanger Bracket

The Heat Exchanger Bracket is integral to the operation of a truck’s cooling system. It supports the heat exchanger, allowing for optimal heat transfer and maintaining the engine within its operational temperature range. This contributes to the overall efficiency and reliability of the cooling system, ensuring the engine operates smoothly under various conditions. By securing the heat exchanger, the bracket helps prevent vibrations and misalignments that could impair cooling performance 2.

Key Features

The Heat Exchanger Bracket is constructed from durable materials, designed to withstand the rigors of commercial truck operations. Its design includes features that enhance stability and alignment of the heat exchanger. Additionally, the bracket may incorporate elements that facilitate easy installation and maintenance, such as pre-drilled holes for mounting screws and compatibility with standard fasteners.

Benefits

The use of the Heat Exchanger Bracket offers several benefits. It contributes to improved cooling efficiency by ensuring the heat exchanger is securely mounted and properly aligned. This can lead to more effective heat dissipation, helping to maintain engine temperature within optimal ranges. The durable construction of the bracket enhances its longevity, potentially reducing the need for frequent replacements and associated costs. Furthermore, by supporting efficient cooling, the bracket can contribute to overall engine reliability and performance.

Installation Process

Installing the Heat Exchanger Bracket requires careful attention to ensure proper alignment and secure mounting of the heat exchanger. The process involves positioning the bracket in its designated location, aligning it with the heat exchanger, and securing it in place using the appropriate fasteners. Tools such as wrenches and screwdrivers may be necessary, depending on the specific design of the bracket and the truck’s cooling system. It is important to follow manufacturer guidelines to ensure correct installation.

Maintenance and Troubleshooting

Regular maintenance of the Heat Exchanger Bracket is important to ensure its continued performance and longevity. This includes checking for signs of wear or damage, ensuring all fasteners are secure, and verifying the alignment of the heat exchanger. Common issues may include loosening of fasteners, which can lead to misalignment of the heat exchanger, or corrosion of the bracket material. Troubleshooting these issues typically involves tightening or replacing fasteners, or in more severe cases, replacing the bracket itself.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations. Cummins’ commitment to excellence is reflected in its extensive research and development efforts, ensuring its products remain at the forefront of technology and performance.

Role of Part 4058110 in Engine Systems

The 4058110 Heat Exchanger Bracket is an integral component in the assembly and functionality of engine systems, particularly when considering the support and front engine components.

In the context of the support component, the Heat Exchanger Bracket serves to securely mount the heat exchanger to the engine structure. This ensures that the heat exchanger remains stable and properly aligned, which is essential for efficient heat transfer and overall system performance. The bracket’s design allows for precise positioning, reducing the risk of misalignment that could lead to inefficiencies or damage.

When integrated with the front engine components, the Heat Exchanger Bracket plays a significant role in maintaining the structural integrity of the engine’s front section. It provides a robust connection point for the heat exchanger, which is often located in the front part of the engine bay. This connection helps in dissipating heat effectively, contributing to the engine’s thermal management system.

Additionally, the bracket aids in reducing vibrations that can be transmitted from the engine to the heat exchanger, ensuring smooth operation and prolonging the lifespan of both components. Its placement also facilitates easier access for maintenance and inspection, enhancing the overall serviceability of the engine system.

Conclusion

The 4058110 Heat Exchanger Bracket is a critical component in the cooling systems of commercial trucks, manufactured by Cummins. Its role in securing the heat exchanger ensures efficient heat transfer and maintains engine temperature within optimal ranges. The durable construction and design features of this part contribute to the overall efficiency, reliability, and longevity of the engine system. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.