This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2867223 Heat Exchanger is a vital component in commercial truck operations, designed to facilitate the transfer of heat between fluids at different temperatures. This process is essential for maintaining optimal operating conditions within the truck’s engine system, contributing to the efficiency and reliability of the vehicle 1.

Basic Concepts of Heat Exchangers

A heat exchanger is a system used to transfer heat between two or more fluids without mixing them. These fluids can be liquids, gases, or a combination of both. The principle behind its operation involves the exchange of thermal energy, which is integral in various applications, including engine cooling systems 2.

Purpose of the Cummins 2867223 Heat Exchanger

This Cummins part serves a significant function within the engine cooling system of a truck. It regulates the temperature of the engine by transferring excess heat from the engine coolant to the ambient air. This process helps maintain the engine within its optimal operating temperature range, which is important for performance and longevity. Additionally, this heat exchanger may have applications beyond engine cooling, such as in heating systems or other temperature-sensitive components within the truck 3.

Key Features

The Cummins 2867223 Heat Exchanger is characterized by its robust design and the use of high-quality materials. It features a compact yet efficient structure that maximizes heat transfer while minimizing space requirements. The materials used in its construction are chosen for their durability and resistance to corrosion, ensuring long-term performance even in demanding environments. Unique attributes of this heat exchanger may include advanced fin designs for enhanced heat dissipation and a construction that allows for easy maintenance and cleaning.

Benefits

The advantages of using the Cummins 2867223 Heat Exchanger include improved engine efficiency and reliability. By effectively managing engine temperatures, it contributes to the overall performance of the truck, potentially leading to fuel savings and reduced wear on engine components. Fleet operators may also experience cost savings due to the heat exchanger’s durability and low maintenance requirements, which can reduce downtime and repair costs.

Installation and Integration

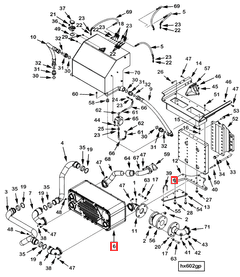

Installing the Cummins 2867223 Heat Exchanger into a truck’s system requires careful consideration of the vehicle’s specific requirements and the existing cooling system configuration. Proper installation involves ensuring compatibility with the engine and cooling system, securing the heat exchanger in place, and connecting it to the appropriate fluid lines. It is important to follow manufacturer guidelines to ensure optimal performance and integration within the system.

Performance and Efficiency

The Cummins 2867223 Heat Exchanger contributes to the overall performance and efficiency of a truck by maintaining engine temperatures within the optimal range. This ensures that the engine operates efficiently, which can lead to improved fuel economy and reduced emissions. Data and examples may show a noticeable improvement in engine performance and fuel efficiency when using this heat exchanger, highlighting its value in commercial truck operations.

Troubleshooting and Maintenance

Common issues with the Cummins 2867223 Heat Exchanger may include blockages, leaks, or reduced efficiency due to fouling. Troubleshooting involves checking for these issues and addressing them promptly to maintain optimal performance. Maintenance practices include regular inspections, cleaning to remove any buildup that may impede heat transfer, and ensuring all connections are secure and free from leaks. Adhering to a maintenance schedule can help ensure the longevity and optimal performance of the heat exchanger.

Environmental Impact

The Cummins 2867223 Heat Exchanger plays a role in reducing the environmental impact of truck operations by contributing to more efficient engine performance. Efficient heat management can lead to lower fuel consumption and reduced emissions, aligning with environmental regulations and promoting sustainability in fleet operations. Its design and materials are also chosen with an eye toward durability and reduced need for replacement, further minimizing its environmental footprint.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a key player in the automotive and heavy-duty truck industry, known for its innovation, quality, and commitment to customer success. The company’s extensive product line and services support a wide range of applications, from on-highway to off-highway and stationary power solutions.

Compatibility of Cummins Heat Exchanger Part 2867223

The Cummins heat exchanger part number 2867223 is designed to integrate seamlessly with several high-performance engines, ensuring optimal thermal management and efficiency. This part is engineered to fit into the cooling systems of the QSK60 and CM850 engines, providing crucial heat exchange functionality.

QSK60 Engines

The QSK60 engines, known for their robust design and high power output, benefit significantly from the precise thermal management offered by the 2867223 heat exchanger. This part ensures that the engine operates within its optimal temperature range, enhancing longevity and performance.

CM850 Engines

Similarly, the CM850 engines, which are widely used in various industrial applications, are well-suited to the 2867223 heat exchanger. The compatibility of this part with the CM850 ensures that the engine maintains efficient heat dissipation, which is critical for sustained performance and reliability.

MCRS Engines

The MCRS engines, another series of Cummins engines, also integrate the 2867223 heat exchanger effectively. This part’s design aligns with the MCRS engines’ requirements, providing a reliable solution for heat exchange needs.

By ensuring compatibility with these engines, the 2867223 heat exchanger from Cummins guarantees that the engines can operate efficiently and reliably, maintaining optimal performance across various applications.

Role of Part 2867223 Heat Exchanger in Engine Systems

The integration of the part 2867223 heat exchanger within engine systems is designed to optimize the thermal management of the engine. This component facilitates the transfer of heat between the engine cooling system and the external environment, ensuring that the engine operates within its optimal temperature range.

In the engine cooling system, the heat exchanger works in conjunction with the radiator, water pump, and thermostat. As coolant circulates through the engine block and cylinder head, it absorbs heat generated by combustion and friction. The heated coolant is then directed to the heat exchanger, where it transfers this heat to the ambient air, cooling down before re-entering the engine. This continuous cycle maintains engine temperature stability, preventing overheating and ensuring efficient operation.

Additionally, the heat exchanger plays a significant role in the overall thermal management strategy of the vehicle. It aids in warming the engine more quickly during cold starts, reducing wear and improving fuel efficiency. Furthermore, in systems where the heat exchanger is part of a larger thermal management system, it can contribute to the heating of the passenger compartment, enhancing comfort.

The effectiveness of the heat exchanger is influenced by factors such as airflow, coolant flow rate, and the design of the heat exchanger itself. Engineers and mechanics must ensure that these factors are optimized to achieve the best performance from the heat exchanger and, by extension, the engine cooling system. Regular maintenance, including cleaning and inspecting the heat exchanger for any signs of damage or corrosion, is essential to maintain its efficiency and longevity.

Conclusion

The Cummins 2867223 Heat Exchanger is a critical component in the thermal management of commercial truck engines. Its role in maintaining optimal engine temperatures contributes to the efficiency, reliability, and environmental performance of the vehicle. Proper installation, maintenance, and understanding of its compatibility with specific engine models are essential for maximizing the benefits of this part.

-

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar Agarwal. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.