This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

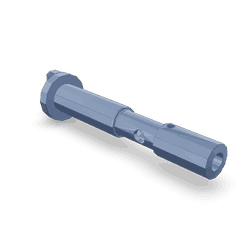

The Cummins 3031683 Governor Plunger is a critical component in the operation of heavy-duty trucks. It plays a significant role in the engine’s fuel injection system, ensuring efficient and reliable performance under various load conditions. Understanding its function and importance is essential for maintaining and optimizing Cummins engines.

Basic Concepts of Governor Plunger

Governor plungers are fundamental components in engine management systems. They regulate fuel delivery based on load and speed requirements, ensuring optimal engine performance by providing the appropriate amount of fuel at any given moment. The governor plunger is a key element in this system, directly influencing fuel injection timing and quantity 1.

Function and Operation

This Cummins part operates within the engine’s fuel injection system to regulate fuel delivery and engine speed. It interacts with the governor mechanism, which senses engine speed and adjusts fuel delivery accordingly. When engine speed changes, the governor plunger moves to alter fuel injection timing, ensuring consistent speed and performance. This interaction with components like the fuel pump and injectors is crucial for efficient engine operation 2.

Key Features

The Cummins 3031683 Governor Plunger is characterized by several key features that enhance its performance and reliability. It is made from high-quality materials for durability and precision engineering. The design allows for smooth operation within the fuel injection system, contributing to overall engine efficiency. Additionally, it is engineered to be compatible with Cummins engines, ensuring seamless integration and optimal performance 3.

Benefits

This part offers several advantages. It contributes to improved fuel efficiency by ensuring precise fuel delivery, reducing unnecessary consumption. Enhanced engine performance is another benefit, as the plunger helps maintain consistent engine speed and power output under varying load conditions. Reliable operation is also a key advantage, designed to withstand the rigors of heavy-duty truck applications 4.

Troubleshooting and Maintenance

Identifying common issues with governor plungers can help maintain engine performance. Symptoms of a malfunctioning plunger may include irregular engine speed, decreased fuel efficiency, or difficulty maintaining consistent power output. Diagnostic procedures involve checking the plunger for wear, ensuring proper alignment within the fuel injection system, and verifying smooth movement without obstruction. Regular maintenance practices, such as cleaning and inspecting the plunger, can help prevent issues and ensure optimal performance.

Installation and Replacement

Installing or replacing the Cummins 3031683 Governor Plunger requires careful attention to detail. The process involves disassembling the fuel injection system to access the plunger, removing the old plunger, and installing the new one. Necessary tools include wrenches, screwdrivers, and possibly specialized tools for fuel injection systems. Precautions such as ensuring the engine is cool and following the manufacturer’s instructions are important to avoid damage and ensure proper fitment. Best practices include verifying the alignment and movement of the new plunger to ensure it functions correctly within the system.

Compatibility and Applications

The Cummins 3031683 Governor Plunger is designed to be compatible with specific Cummins engine models, ensuring it fits and functions correctly within those systems. Its suitability for various heavy-duty truck applications makes it a versatile component for fleet managers and maintenance professionals. Understanding its compatibility helps in selecting the right part for engine repairs or upgrades.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its high-quality products and innovative solutions in the automotive industry. With a history of providing reliable and efficient engine technologies, Cummins has established a strong reputation for excellence. The 3031683 Governor Plunger is part of Cummins’ extensive product lineup, reflecting the company’s commitment to delivering components that enhance engine performance and reliability.

Understanding the Role of the Governor Plunger in Engine Systems

The governor plunger, specifically part 3031683, is integral to the regulation and control of engine speed. This component works in conjunction with several other engine components to ensure optimal performance and efficiency.

Interaction with the Fuel Injection System

In diesel engines, the governor plunger is a key part of the fuel injection system. It interacts directly with the fuel rack, which controls the amount of fuel delivered to the injectors. As the governor plunger moves, it adjusts the position of the fuel rack, thereby modulating the fuel supply. This ensures that the engine operates within the desired speed range under varying load conditions.

Coordination with the Flyweight Mechanism

The governor plunger is also closely linked to the flyweight mechanism. As the engine speed changes, the centrifugal force acting on the flyweights varies. This movement is transmitted to the governor plunger, which then makes the necessary adjustments to the fuel rack to maintain consistent engine speed. The precision of this interaction is essential for smooth engine operation.

Role in the Governor Housing

Housed within the governor assembly, the plunger operates in a controlled environment that includes springs, levers, and other mechanical components. The governor housing provides a stable platform for the plunger to function, shielding it from external vibrations and ensuring accurate speed control.

Integration with the Linkage System

The governor plunger is connected to various linkage components that transmit its movements to other parts of the engine. These linkages are designed to amplify or modify the plunger’s motion as needed, allowing for fine-tuned control over the engine’s speed. The accuracy of these linkages is vital for the overall performance of the governor system.

Contribution to Engine Stability

By maintaining a consistent engine speed, the governor plunger contributes to the overall stability of the engine. This is particularly important in applications where precise speed control is required, such as in generators, marine engines, and heavy-duty machinery. The governor plunger ensures that the engine can respond quickly to changes in load without significant fluctuations in speed.

Synergy with the Throttle Mechanism

In some engine designs, the governor plunger also interacts with the throttle mechanism. This synergy allows for additional layers of control, enabling the engine to operate efficiently across a wide range of conditions. The throttle mechanism can provide coarse adjustments, while the governor plunger offers fine-tuning, resulting in a more responsive and stable engine performance.

Conclusion

The Cummins 3031683 Governor Plunger is a vital component in the fuel injection system of Cummins engines, ensuring efficient and reliable engine performance. Its precise regulation of fuel delivery and interaction with other engine components contribute to consistent engine speed and power output. Understanding its function, benefits, and maintenance requirements is essential for optimizing engine performance and reliability.

-

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions: Fundamentals, Selection, Design and Application. Springer Vieweg.

↩ -

Jazar, R. N. (2017). Vehicle Dynamics: Theory and Application. Springer.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.