This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

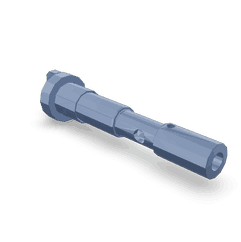

The Cummins 3010811 Governor Plunger is a component designed for use in heavy-duty trucks. It plays a role in the engine’s fuel injection system by helping to regulate engine speed and maintain consistent performance under varying load conditions. This part is integral to ensuring that the engine operates efficiently and reliably, contributing to the overall performance and longevity of the vehicle.

Basic Concepts of Governor Plunger

A governor plunger operates on the principle of controlling engine speed by adjusting the fuel delivery to the engine. It responds to changes in engine load and speed, making necessary adjustments to maintain optimal performance. The governor plunger works in conjunction with other components of the fuel injection system to ensure that the engine runs smoothly and efficiently across a range of operating conditions 1.

Purpose of the 3010811 Governor Plunger

The specific role of the 3010811 Governor Plunger in a truck’s operation is to regulate the fuel injection timing and quantity. It interacts with the engine’s governor mechanism to adjust the fuel delivery based on the engine’s speed and load. This regulation helps in achieving a balance between power output and fuel efficiency, ensuring that the engine operates within its designed parameters 2.

Key Features

The 3010811 Governor Plunger is characterized by its precise design and the materials used in its construction. It is typically made from high-quality metals to ensure durability and resistance to wear. The design of the plunger allows for smooth operation within the governor mechanism, contributing to its effectiveness in regulating engine speed and performance.

Benefits

The advantages provided by the 3010811 Governor Plunger include improved engine performance, enhanced fuel efficiency, and increased reliability. By ensuring that the engine operates at optimal speeds under various conditions, this component helps in reducing fuel consumption and emissions, while also contributing to the engine’s longevity 3.

Installation and Integration

Installing the 3010811 Governor Plunger involves several steps, including preparing the engine compartment, removing the old plunger (if applicable), and carefully fitting the new component into place. It is important to follow the manufacturer’s guidelines for installation to ensure proper integration with other engine components. Tools required may include wrenches, screwdrivers, and possibly a torque wrench to ensure components are tightened to the correct specifications.

Troubleshooting Common Issues

Common problems associated with the 3010811 Governor Plunger may include irregular engine speed, difficulty in starting the engine, or a decrease in fuel efficiency. Troubleshooting steps may involve inspecting the plunger for signs of wear or damage, checking the governor mechanism for proper operation, and ensuring that all connections are secure and free from leaks.

Maintenance Tips

Regular maintenance practices for the 3010811 Governor Plunger include periodic inspection for wear and damage, cleaning to remove any buildup that may affect its operation, and following the manufacturer’s guidelines for replacement intervals. Keeping the plunger and its associated components in good condition is key to ensuring the optimal performance and longevity of the engine.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry, particularly in the manufacture of diesel engines and components. The company’s product range includes a variety of engines and parts designed for heavy-duty applications, reflecting its commitment to performance, efficiency, and reliability.

Cummins Governor Plunger 3010811 Compatibility

The Cummins Governor Plunger part number 3010811 is designed to fit a variety of Cummins engines, ensuring precise control over engine speed and performance. Here are the engines with which this governor plunger is compatible:

K-Series Engines

- K19

- K38

- K50

These engines are known for their robust design and reliability, often used in heavy-duty applications. The governor plunger is crucial for maintaining the correct engine speed and ensuring smooth operation.

L-Series Engines

- L10 MECHANICAL

The L10 MECHANICAL engine is a mechanical version of the L10 series, providing dependable performance for various industrial applications. The governor plunger plays a vital role in regulating the engine’s speed and fuel delivery.

N-Series Engines

- N14 MECHANICAL

The N14 MECHANICAL engine is another robust option, commonly used in heavy-duty trucks and industrial machinery. The governor plunger ensures that the engine operates within its optimal speed range, enhancing efficiency and longevity.

NH/NT Series Engines

- NH/NT 855

The NH/NT 855 engine is part of the NH/NT series, known for its power and reliability in various applications. The governor plunger is essential for maintaining the engine’s speed and ensuring consistent performance.

V-Series Engines

- V28

- V903

The V28 and V903 engines are part of the V-Series, offering high performance and durability. The governor plunger is a critical component for controlling engine speed and ensuring smooth operation across different load conditions.

By ensuring compatibility with these engines, the Cummins Governor Plunger 3010811 helps maintain the performance and reliability of various Cummins engine models.

Role of Part 3010811 Governor Plunger in Engine Systems

The Governor Plunger, identified by part number 3010811, is an essential component in the regulation and control of fuel delivery within various engine systems. Its function is integral to maintaining the desired engine performance and efficiency across different operational conditions.

Integration with Fuel Systems

-

AFC vs Fuel Pump and AFC-VS/Road Speed: The Governor Plunger works in conjunction with the AFC (Automatic Fuel Control) system to modulate fuel delivery based on engine load and road speed. It ensures that the fuel pump delivers the correct amount of fuel to match the engine’s demand, optimizing performance and fuel economy.

-

Base Fuel Pump and Cummins Electronic Fuel Control Governor: In systems utilizing a base fuel pump, the Governor Plunger interacts with the Cummins Electronic Fuel Control Governor to fine-tune fuel delivery. This interaction is vital for precise control over fuel injection, which is critical for engine responsiveness and emissions control.

-

EBM: Pump and Base Fuel: Within the EBM (Engine Braking Module) system, the Governor Plunger helps regulate the base fuel supply. This ensures that the engine braking function operates smoothly without disrupting the overall fuel delivery system.

Fuel Injection and Governor Systems

-

FP & Gov Sump and FP & Gov. Sump: The Governor Plunger is directly involved in the operation of the fuel pump and governor sump. It helps maintain the correct pressure and flow of fuel within the sump, which is essential for consistent fuel injection.

-

Fuel Aftercooler Pump and Fuel Injection Pump: In systems equipped with a fuel aftercooler pump, the Governor Plunger ensures that the fuel injection pump receives a steady and regulated fuel supply. This is important for maintaining optimal injection timing and pressure.

-

Fuel Pump & Acc Drive and Fuel Pump & Cal: The Governor Plunger also plays a role in systems where the fuel pump is driven by an accessory drive. It ensures that calibration settings are adhered to, providing consistent fuel delivery across varying engine speeds and loads.

Specialized Fuel Pump Systems

-

Fuel Pump & Cal Code and Fuel Pump & Cal.Code: In systems that require a calibration code, the Governor Plunger ensures that the fuel pump operates within the specified parameters. This is particularly important in high-precision fuel delivery systems.

-

Fuel Pump & Drive (Cust) and Fuel Pump AFC-VS: Custom fuel pump drives often incorporate the Governor Plunger to adapt fuel delivery to specific customer requirements. The AFC-VS system benefits from this component to enhance fuel control and engine performance.

Non-AFC and Woodward Governor Systems

-

Non AFC-VS FP/Gov. Sump and Non-AFC VS FP/WW Sump: For non-AFC systems, the Governor Plunger ensures that the fuel pump and governor sump operate efficiently. It adapts to different sump configurations, maintaining optimal fuel delivery.

-

Woodward PSG Governor: In systems utilizing a Woodward PSG Governor, the Governor Plunger is a key component in the governor mechanism. It ensures that the Woodward governor can effectively control fuel delivery, enhancing engine stability and performance.

Additional Components

-

Governor Cover and Injector Stand Audit Kit: The Governor Plunger is often housed within the governor cover, protecting it from contaminants and ensuring its longevity. The injector stand audit kit may include the Governor Plunger to verify and maintain the integrity of the fuel delivery system.

-

Non-AFC vs FP/Gov. Sump and Pump, Fuel Uncalibrated: In uncalibrated fuel systems, the Governor Plunger provides a baseline for fuel regulation, ensuring that the pump delivers fuel within acceptable parameters until calibration can be performed.

The Governor Plunger, part number 3010811, is a versatile and essential component in various engine fuel delivery systems. Its role in regulating and controlling fuel flow ensures that engines operate efficiently and effectively across a wide range of conditions.

Conclusion

The Cummins 3010811 Governor Plunger is a critical component in the fuel injection system of heavy-duty trucks, ensuring efficient and reliable engine operation. Its precise design and integration with various engine systems contribute to optimal engine performance, fuel efficiency, and longevity. Regular maintenance and proper installation are essential to maximize the benefits of this component.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.