This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

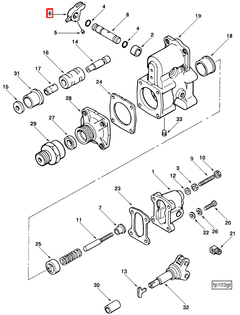

The Governor Lever 100484, a component manufactured by Cummins, plays a significant role in the operation of commercial trucks. Cummins, a prominent name in the automotive industry, is renowned for its diesel engines. This lever is essential for ensuring that the engine performs efficiently under various conditions.

Function and Operation

The Governor Lever 100484 operates within the engine system to regulate engine speed. It interacts with the engine’s governor mechanism, which controls fuel delivery based on load and speed requirements. By adjusting the position of the governor lever, the engine’s speed can be modulated to meet operational demands, ensuring smooth and consistent performance 1.

Purpose of the Governor Lever

The primary function of the Governor Lever 100484 is to maintain consistent engine performance under varying load conditions. It balances the fuel supply with the engine’s speed, preventing over-revving or under-performance, which could lead to inefficient operation or potential damage to the engine 2.

Key Features

The Governor Lever 100484 is designed with features that enhance its functionality and durability. Constructed from high-quality materials, it is built to withstand the rigors of commercial truck operation. Its design allows for precise adjustments, ensuring accurate control over engine speed. Additionally, it is engineered to integrate seamlessly with Cummins engines, promoting efficient operation 3.

Benefits

The use of the Governor Lever 100484 offers several advantages. It contributes to improved fuel efficiency by ensuring that the engine operates within optimal speed ranges. This enhances overall engine performance and increases the reliability of the engine system. The lever’s precise control capabilities help in reducing wear and tear on engine components, leading to longer service intervals and lower maintenance costs.

Installation and Compatibility

Proper installation of the Governor Lever 100484 is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure it functions correctly within the engine system. Compatibility information for specific engine models will be provided separately to ensure the correct application of this component.

Maintenance and Troubleshooting

Routine maintenance of the Governor Lever 100484 is recommended to ensure its optimal performance and longevity. This includes regular inspections for wear or damage and ensuring that all connections are secure. Troubleshooting tips will be provided to address common issues that may arise, facilitating quick and effective resolutions.

Common Issues and Solutions

Frequent problems associated with the Governor Lever 100484 may include wear on the lever itself or issues with its connection to the governor mechanism. Suggested solutions will be outlined to address these issues effectively, ensuring the continued reliable operation of the engine.

Safety Considerations

When working with the Governor Lever 100484, it is important to observe safety protocols and precautions. This includes ensuring the engine is off and cool before beginning any work, using appropriate personal protective equipment, and following all manufacturer guidelines to prevent accidents and ensure personal safety.

Cummins Corporation

Cummins is a leading manufacturer in the automotive industry, with a broad product range that includes diesel engines, natural gas engines, and related technologies. The company has a reputation for quality, innovation, and reliability, making it a preferred choice for commercial vehicle operators worldwide.

Compatibility with Cummins Engines

The Governor Lever, identified by the part number 100484, is compatible with certain Cummins engines. This part is designed to regulate engine speed by controlling the fuel delivery mechanism.

Cummins K38 Engine

The Governor Lever is compatible with the Cummins K38 engine. This engine is known for its robust design and efficiency, often used in heavy-duty applications. The Governor Lever in this engine ensures smooth and precise control over the engine’s RPM, contributing to overall performance and longevity.

Cummins K50 Engine

Similarly, the Governor Lever is also suitable for the Cummins K50 engine. This engine is another variant in Cummins’ lineup, recognized for its reliability and power. The Governor Lever in the K50 engine plays a vital role in maintaining consistent engine speed, which is crucial for the engine’s operational efficiency and durability.

Grouping of Engines

Both the K38 and K50 engines fall under the category of heavy-duty engines, where precise control over engine speed is paramount. The Governor Lever, part number 100484, is engineered to meet the demands of these engines, ensuring that they operate within their optimal performance parameters. This compatibility highlights the versatility and precision of Cummins’ design in creating components that fit seamlessly into their engine systems.

Understanding the Role of Governor Lever in Engine Systems

The Governor Lever (Part 100484) is an integral component in the regulation and control of various engine systems. Its primary function is to modulate the fuel delivery and turbocharger operation, ensuring optimal performance and efficiency.

Interaction with Fuel System Components

-

Fuel Filter and Damper: The Governor Lever works in conjunction with the fuel filter and damper to maintain a consistent fuel flow. By adjusting the lever, the system can compensate for variations in fuel pressure, ensuring a steady supply to the engine.

-

Fuel Pump and Drive: When the Governor Lever is engaged, it influences the operation of the fuel pump and drive mechanism. This interaction helps in fine-tuning the fuel pressure according to the engine’s demand, enhancing overall performance.

-

Fuel Pump: The lever’s position directly affects the fuel pump’s output. By modulating the lever, the system can increase or decrease fuel delivery, which is essential for maintaining the correct air-fuel ratio.

-

Fuel Pump (VS & TC): In systems equipped with Variable Speed (VS) and Turbocharged (TC) components, the Governor Lever plays a significant role. It ensures that the fuel pump operates within the required parameters, adapting to changes in engine load and speed.

Coordination with Turbocharger and Governor Components

-

Turbocharger F.P. Kit: The Governor Lever is part of the turbocharger fuel pressure (F.P.) kit. It helps in regulating the fuel pressure to the turbocharger, ensuring that it operates efficiently under varying conditions.

-

Governor Spring Cover and Pack: The lever interacts with the governor spring cover and spring pack to maintain the desired fuel pressure. This coordination is vital for the stable operation of the turbocharger and fuel injection system.

-

Turbocharger Governor Pack Spring: By adjusting the Governor Lever, the spring tension within the turbocharger governor pack can be modified. This allows for precise control over the turbocharger’s speed and fuel delivery, optimizing engine performance.

Fuel Injection and Pump Systems

-

Fuel Injection Pump: The Governor Lever’s role extends to the fuel injection pump, where it helps in modulating the injection timing and pressure. This ensures that the fuel is delivered at the right moment and with the correct pressure, enhancing combustion efficiency.

-

Fuel (Uncalibrated): In systems where the fuel is uncalibrated, the Governor Lever provides a means to manually adjust the fuel delivery. This is particularly useful during maintenance or when fine-tuning the engine for specific applications.

Conclusion

In summary, the Governor Lever (Part 100484) is a key component in the intricate network of engine systems. Its ability to modulate fuel delivery and turbocharger operation ensures that the engine operates smoothly and efficiently under a wide range of conditions.

-

Road and Off-Road Vehicle Dynamics, Moustafa ElGindy and Zeinab ElSayegh, Springer Nature, 2023

↩ -

Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings, Dominique Bonneau, Aurelian Fatu and Dominique Souchet, Wiley-ISTE, 2014

↩ -

Mobile Equipment Hydraulics A Systems and Troubleshooting Approach, Ben Watson, Cengage Learning, 2011

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.