This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

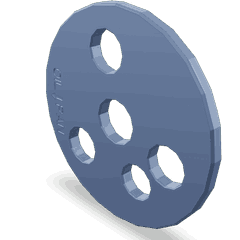

The 5558803 Gear Retainer is a component manufactured by Cummins, a well-established name in the commercial truck industry. This Cummins part is significant in the context of commercial truck operations due to its role in maintaining the integrity and efficiency of the truck’s engine system.

Basic Concepts of Gear Retainers

Gear retainers are mechanical components designed to hold gears in place within an engine or transmission system. They ensure that gears remain correctly positioned and aligned, which is vital for the smooth operation of the mechanical system 1. In the context of truck engines, gear retainers help maintain the precise alignment of gears, which is crucial for efficient power transmission and overall engine performance 2.

Purpose of the 5558803 Gear Retainer

The 5558803 Gear Retainer plays a role in the operation of a truck by securing gears within the engine’s gear system. Its function is to keep the gears in their designated positions, ensuring that they mesh correctly and operate smoothly. This is particularly important in high-stress environments such as commercial trucking, where engine reliability and performance are paramount 3.

Key Features

The 5558803 Gear Retainer is designed with specific characteristics that contribute to its effectiveness and durability. It is typically made from high-strength materials that can withstand the rigors of commercial truck operations. The design of the retainer ensures a secure fit around the gears, minimizing the risk of misalignment or movement during operation.

Benefits

The 5558803 Gear Retainer offers several advantages. It enhances gear stability by securely holding gears in place, which reduces the likelihood of gear slippage or misalignment. This results in reduced wear on the gear system and contributes to enhanced engine performance. Additionally, the retainer helps in maintaining the overall efficiency of the engine by ensuring that power is transmitted smoothly through the gear system 4.

Installation Process

Installing the 5558803 Gear Retainer requires careful attention to ensure it is correctly positioned and secured. The process typically involves aligning the retainer with the gears and using appropriate tools to fix it in place. It is important to follow manufacturer guidelines to ensure proper installation, which may include specific torque settings or alignment checks.

Common Issues and Troubleshooting

Gear retainers, including the 5558803, can encounter issues such as wear, damage, or misalignment. These problems can be diagnosed through regular inspections and by monitoring the engine’s performance. Solutions may involve replacing the retainer or addressing any underlying issues that could be causing the problems.

Maintenance Tips

Regular maintenance of the 5558803 Gear Retainer is important for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, ensuring it remains securely in place, and addressing any issues promptly. Proper maintenance helps in preventing more significant problems down the line and ensures the engine operates efficiently.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engine components. The company’s product range includes a variety of parts and systems designed to meet the demanding requirements of commercial trucking 5.

Conclusion

The 5558803 Gear Retainer is a vital component in the maintenance and operation of Cummins engines, particularly within the X15 CM2450 and X134B engine families. Its role in securing gears and ensuring their proper alignment is crucial for the efficient and reliable operation of these engines. Regular maintenance and proper installation are key to maximizing the performance and longevity of this part.

-

Qianfan Xin, Diesel Engine System Design, Woodhead Publishing, 2011.

↩ -

Robert Bosch GmbH, Bosch Automotive Handbook 9th Edition, Robert Bosch GmbH, 2014.

↩ -

Sean Bennett, Ian Andrew Norman, Heavy Duty Truck Systems, Fifth Edition, Delmar Cengage Learning, 2011.

↩ -

Sean Bennett, Ian Andrew Norman, Heavy Duty Truck Systems Fifth Edition, Delmar Cengage Learning, 2011.

↩ -

Cummins Inc., Company Overview, [Accessed on Date].

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.