This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

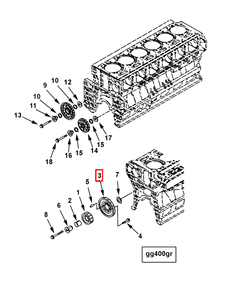

The Cummins 4095473 Idler Gear is a component designed for use in commercial trucks. Its purpose is to facilitate the smooth operation of the gear system within these vehicles. The significance of this part lies in its ability to enhance the efficiency and reliability of the truck’s transmission system, contributing to overall vehicle performance.

Basic Concepts of Idler Gears

An idler gear is a type of gear used in gear systems to transmit motion between two non-adjacent gears. It functions by meshing with both the driving and driven gears, allowing for the transfer of rotational force. Idler gears are commonly employed in mechanical systems to change the direction of rotation, provide additional gear reduction, or to fill gaps between gears. Their application is widespread across various machinery and vehicles, including commercial trucks 1.

Purpose of the 4095473 Idler Gear

The Cummins 4095473 Idler Gear plays a specific role within the gear system of a truck. It is positioned to mesh with both the input and output gears, ensuring smooth transmission of power. This gear contributes to the truck’s performance by maintaining the correct spacing and alignment between gears, which is vital for efficient power transfer and reduced wear on the gear teeth 2.

Key Features

The Cummins 4095473 Idler Gear is characterized by its precise design and the materials used in its construction. It is typically made from high-strength alloys to withstand the rigors of commercial truck operations. Unique characteristics of this idler gear may include specific tooth profiles and heat treatments that enhance its durability and performance under heavy loads 3.

Benefits of Using the 4095473 Idler Gear

Incorporating the Cummins 4095473 Idler Gear into a truck’s gear system offers several advantages. These include improved efficiency in power transmission, enhanced durability under demanding conditions, and overall better performance of the gear system. The use of high-quality materials and precise engineering ensures that this idler gear can withstand the stresses of commercial truck operations, leading to longer service life and reduced maintenance requirements.

Installation Considerations

Proper installation of the Cummins 4095473 Idler Gear is important for ensuring its effective operation. Guidelines for installation may include verifying the correct alignment with adjacent gears, ensuring proper lubrication, and following manufacturer recommendations for torque settings. Special instructions might be provided to address specific aspects of the installation process, such as the need for particular tools or the sequence of operations.

Troubleshooting Common Issues

Common problems associated with idler gears can include noise, vibration, or premature wear. Potential causes for these issues may range from misalignment to insufficient lubrication. Troubleshooting steps often involve inspecting the gear for signs of wear, checking the alignment with adjacent gears, and ensuring that lubrication levels are adequate. Addressing these issues promptly can help maintain the efficiency and longevity of the gear system.

Maintenance Tips

Maintaining the Cummins 4095473 Idler Gear is key to ensuring its longevity and optimal performance. Regular inspection practices should include checking for signs of wear or damage, ensuring proper alignment, and maintaining adequate lubrication. Recommended maintenance schedules may vary depending on the specific operating conditions but generally involve periodic checks and lubrication changes to prevent issues related to wear and tear.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, which are designed to meet the demanding requirements of commercial applications.

Idler Gear 4095473 Compatibility with Cummins Engines

The Idler Gear 4095473, manufactured by Cummins, is a critical component designed to fit seamlessly within several of their engine models. This part plays a pivotal role in the engine’s operation by ensuring the proper alignment and smooth functioning of the timing system.

QSK23 Series

The Idler Gear 4095473 is compatible with the QSK23 series engines, including the QSK23 CM2250 K109 and QSK23 CM2350 K127 models. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The idler gear ensures that the timing components operate in harmony, maintaining the engine’s efficiency and longevity.

QSK23 CM500

Similarly, the Idler Gear 4095473 is also designed to fit the QSK23 CM500 engine. This model is part of the QSK23 series and is engineered for high-performance applications, requiring precise timing mechanisms to function optimally. The idler gear’s role in this engine is crucial for maintaining the synchronization of the engine’s moving parts, ensuring smooth operation and reducing wear and tear.

By integrating the Idler Gear 4095473 into these engines, Cummins ensures that the timing system operates smoothly, contributing to the overall reliability and performance of the engine. This compatibility highlights Cummins’ commitment to providing high-quality, durable components that enhance the functionality of their engines.

Role of Part 4095473 Idler Gear in Engine Systems

The 4095473 Idler Gear is an integral component within various engine systems, facilitating the smooth operation of several key elements. Positioned within the gear train, this idler gear ensures proper alignment and tension between the driving and driven gears, which is essential for the efficient transfer of power.

In the cylinder block, the idler gear works in conjunction with the main gear system to maintain consistent rotational speeds and reduce wear on other components. It helps in distributing the load evenly across the gear teeth, which prolongs the lifespan of the cylinder block and enhances overall engine performance.

Within the cam follower assembly, the 4095473 Idler Gear plays a significant role by ensuring that the camshaft and crankshaft remain in sync. This synchronization is vital for the precise timing of valve operations, which directly impacts the engine’s efficiency and power output. The idler gear helps mitigate any potential misalignment that could arise from thermal expansion or mechanical wear.

In gear systems, the idler gear serves as a mediator between the driving and driven gears. It allows for flexibility in gear arrangement, enabling engineers to design more compact and efficient engine layouts. By altering the direction of rotation and maintaining proper meshing, the idler gear ensures that power is transmitted smoothly without unnecessary friction or energy loss.

Overall, the 4095473 Idler Gear is a fundamental component that enhances the reliability and performance of engine systems by ensuring proper gear alignment, tension, and synchronization.

Conclusion

The Cummins 4095473 Idler Gear is a vital component in the gear systems of commercial trucks and Cummins engines, ensuring smooth operation, efficient power transmission, and enhanced durability. Its precise design, high-strength materials, and compatibility with various engine models make it a critical part for maintaining the performance and reliability of these vehicles. Proper installation, maintenance, and troubleshooting are essential for maximizing the benefits of this idler gear, contributing to the overall efficiency and longevity of the gear system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.