This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3423422 Flange Gasket is a component designed for use in commercial truck operations. It serves a specific function within the engine and exhaust systems of these vehicles, contributing to the overall efficiency and reliability of the truck’s performance.

Basic Concepts of Flange Gaskets

Flange gaskets are sealing components used between flanged joints in mechanical systems. Their primary function is to create a tight seal, preventing the leakage of fluids or gases. They are essential in maintaining the integrity of the system by ensuring that the connection between two flanges remains secure under various operating conditions 2.

Purpose of the 3423422 Flange Gasket

The 3423422 Flange Gasket is specifically designed for use in commercial trucks. It plays a role in sealing the connections within the engine and exhaust systems. By providing a reliable seal, it helps maintain the efficiency of the engine and ensures that exhaust gases are properly directed away from the engine compartment.

Key Features

The 3423422 Flange Gasket is constructed from materials that offer durability and resistance to high temperatures and pressures. Its design specifications are tailored to meet the demanding conditions found in commercial truck operations. Unique attributes of this gasket include its ability to withstand thermal cycling and mechanical stress, which are common in heavy-duty applications 1.

Benefits

The use of the 3423422 Flange Gasket offers several advantages. It provides improved sealing efficiency, which is vital for maintaining engine performance. Its resistance to high temperatures and pressures ensures longevity, even in harsh operating conditions. Additionally, the gasket’s design contributes to the overall reliability of the truck’s engine and exhaust systems.

Installation Process

Proper installation of the 3423422 Flange Gasket involves several steps. First, the flange surfaces must be prepared to ensure a clean and smooth contact area. Then, the gasket should be positioned correctly between the flanges. Torque specifications must be followed to secure the flanges without over-tightening, which could damage the gasket. Best practices include using the correct tools and following a systematic approach to ensure a secure fit 2.

Common Issues and Troubleshooting

Flange gaskets can encounter issues such as leaks or failures over time. Common causes include improper installation, wear and tear, or exposure to extreme conditions. Troubleshooting these problems may involve inspecting the gasket for damage, ensuring proper torque has been applied, and verifying that the flange surfaces are clean and undamaged. Addressing these issues promptly can prevent more significant problems down the line.

Maintenance Tips

To maintain the 3423422 Flange Gasket, regular inspection intervals are recommended. Cleaning the gasket and flange surfaces can help prevent buildup that may affect sealing efficiency. Guidelines for replacement should be followed to ensure the gasket continues to perform effectively throughout its service life.

About Cummins

Cummins Inc. is a well-established manufacturer known for its diesel engines and related components for commercial vehicles. With a history of innovation and quality, Cummins offers a range of products designed to meet the needs of various industries. The company’s reputation for reliability and performance makes its components, like the 3423422 Flange Gasket, a popular choice for commercial truck applications.

Compatibility with Cummins Engines

The Flange Gasket part number 3423422, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This gasket is crucial for ensuring a secure seal between flanges, preventing leaks and maintaining the integrity of the engine system.

Cummins QSV81G and QSV91G Engines

For the Cummins QSV81G and QSV91G engines, the flange gasket 3423422 is engineered to fit precisely in the specified flange areas. These engines are part of the Cummins QSV series, known for their robust performance and reliability in various applications. The gasket’s design ensures it can withstand the operational pressures and temperatures typical of these engines, providing a long-lasting and dependable seal.

Installation and Maintenance

Proper installation of the flange gasket 3423422 is essential for optimal engine performance. It is recommended to follow the manufacturer’s guidelines for torque specifications and installation procedures to avoid any potential issues. Regular maintenance checks should be conducted to ensure the gasket remains in good condition and continues to provide an effective seal.

Importance of the Gasket

The flange gasket 3423422 plays a critical role in the overall functionality of the engine. By preventing leaks and maintaining pressure, it helps to ensure the engine operates efficiently and safely. This gasket is a key component in the engine’s sealing system, contributing to the longevity and reliability of the engine.

Role of Part 3423422 Flange Gasket in Engine Systems

The part 3423422 Flange Gasket is an essential component in ensuring the efficient and safe operation of various engine systems. Its primary function is to create a secure seal between different components, preventing leaks and ensuring optimal performance.

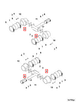

Air Fuel Assembly Mixer and Assembly Mixer Air Fuel

In the air fuel assembly mixer and the assembly mixer air fuel, the flange gasket ensures a tight seal between the mixer components. This seal is vital for maintaining the correct air-fuel ratio, which is necessary for efficient combustion and engine performance. Any leakage could result in an imbalance, leading to reduced efficiency and potential engine damage.

Filter Assembly Shell and Filter Shell and Gas Mixers

For the filter assembly shell and the filter shell integrated with gas mixers, the flange gasket plays a significant role in maintaining the integrity of the filtration process. It ensures that the filtered air and gas mix properly without any external contaminants entering the system, which could otherwise compromise engine performance and longevity.

Gas Modules (P=1, 2.5bar; P=1, 8bar; P=3bar)

In gas modules operating at different pressures (1 bar, 2.5 bar, 8 bar, and 3 bar), the flange gasket is instrumental in maintaining the required pressure levels. It prevents gas leakage, which is essential for the module to function correctly and deliver the precise amount of gas needed for combustion. This precision is key to achieving optimal engine performance and fuel efficiency.

Fuel Control Module and Gas Module

The fuel control module and the gas module rely on the flange gasket to ensure that the fuel and gas systems remain sealed. This seal is important for maintaining the correct fuel-to-gas ratio and pressure, which are critical for the engine’s combustion process. A well-sealed system ensures that the engine operates smoothly and efficiently.

Seal Gas Supply Kit

In the seal gas supply kit, the flange gasket is used to create a reliable seal in the gas supply lines. This ensures that the gas is delivered to the engine components without any loss of pressure or contamination, which is essential for maintaining the engine’s performance and safety.

Conclusion

Overall, the part 3423422 Flange Gasket is a fundamental component in various engine systems, ensuring that all connections are sealed properly to maintain efficiency, performance, and safety.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.