This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

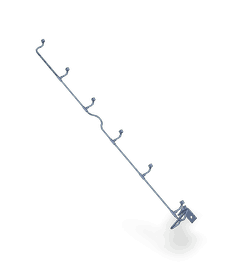

The Cummins 3922117 Fuel Manifold is a component designed for use in heavy-duty trucks. It plays a role in the fuel system by facilitating the distribution of fuel to the injectors. This part is integral to the efficient operation of the engine, ensuring that fuel is delivered consistently and effectively to support combustion and power generation.

Basic Concepts of Fuel Manifolds

A fuel manifold is a device used in diesel engines to distribute fuel to multiple injectors. Its function is to receive pressurized fuel from the fuel pump and then channel it to each injector in the engine. This ensures that each cylinder receives the appropriate amount of fuel for combustion, contributing to the overall performance and efficiency of the truck 1. The design and operation of the fuel manifold are important for maintaining engine balance and power output.

Purpose of the Cummins 3922117 Fuel Manifold

The Cummins 3922117 Fuel Manifold is specifically engineered to distribute fuel to the injectors in heavy-duty truck engines. By ensuring a consistent and precise flow of fuel, it plays a role in enhancing engine performance, promoting efficient combustion, and supporting the overall reliability of the truck’s fuel system. Its design allows for optimal fuel distribution, which is vital for the engine’s operation under various load conditions.

Key Features

The Cummins 3922117 Fuel Manifold is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and wear, ensuring longevity in demanding environments. The design of the manifold includes precise engineering to facilitate smooth and consistent fuel flow. Additionally, it may incorporate features such as integrated sensors or connectors that support the engine’s electronic control system, further enhancing its functionality.

Benefits of Using the Cummins 3922117 Fuel Manifold

Utilizing the Cummins 3922117 Fuel Manifold offers several advantages. It provides improved fuel distribution, which contributes to more efficient combustion and enhanced engine performance. The manifold’s robust construction and precise engineering support increased reliability, reducing the likelihood of fuel system failures. Additionally, its compatibility with Cummins engines ensures seamless integration and optimal performance within the specified applications.

Installation Process

Installing the Cummins 3922117 Fuel Manifold involves several steps to ensure proper integration into the truck’s fuel system. Begin by disconnecting the battery to prevent any electrical issues. Remove the old manifold, taking care to note the routing of fuel lines and any connections. Install the new manifold, ensuring all connections are secure and fuel lines are properly routed. Reconnect the battery and perform a system check to confirm proper operation. Tools required may include wrenches, screwdrivers, and possibly a torque wrench to ensure proper tightening of connections.

Common Issues and Troubleshooting

Common issues with the Cummins 3922117 Fuel Manifold may include fuel leaks, inconsistent fuel delivery, or corrosion. To address these problems, begin by inspecting all connections for tightness and signs of wear or damage. Check for leaks in the fuel lines and manifold body. If corrosion is present, consider cleaning the affected areas or replacing damaged components. Regular maintenance and inspections can help identify and resolve issues before they lead to significant problems.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 3922117 Fuel Manifold, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or leaks. Cleaning the manifold and its connections can prevent buildup that may affect fuel flow. Additionally, replacing worn-out components, such as seals or gaskets, can help maintain the integrity of the fuel system. Following the manufacturer’s guidelines for maintenance intervals and procedures will support the continued reliable operation of the manifold.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for producing high-quality, reliable components for a variety of applications, including heavy-duty trucks. The company’s commitment to innovation, quality, and customer satisfaction has made it a trusted name in the automotive and industrial sectors.

Cummins Fuel Manifold 3922117 Compatibility

The Cummins Fuel Manifold part number 3922117 is designed to integrate seamlessly with a variety of Cummins engines, ensuring optimal fuel delivery and performance. This part is engineered to fit precisely with the following engines:

- 6C8.3

The 3922117 Fuel Manifold is meticulously crafted to meet the specific requirements of these engines, ensuring compatibility and reliability. It is important for maintaining the efficiency and longevity of the engine by providing a consistent and precise fuel supply.

When installing the 3922117 Fuel Manifold, it is important to follow the manufacturer’s guidelines to ensure proper fitment and function. This part is a key component in the fuel system, contributing to the overall performance and efficiency of the engine.

For optimal results, it is recommended to use genuine Cummins parts, such as the 3922117 Fuel Manifold, to maintain the integrity and performance of the engine.

Role of Part 3922117 Fuel Manifold in Engine Systems

The 3922117 Fuel Manifold is an integral component in the fuel delivery system of various engine setups. It serves as a central hub where fuel is distributed from the fuel lines to the individual fuel injectors. This ensures that each cylinder receives the precise amount of fuel required for optimal combustion.

Integration with Fuel Plumbing

The Fuel Manifold interfaces directly with the fuel plumbing system. It connects to the main fuel supply line, which delivers pressurized fuel from the fuel pump. The manifold then channels this fuel into smaller, dedicated lines that lead to each fuel injector. This setup allows for efficient and even distribution of fuel, minimizing the risk of fuel starvation or over-fueling in any particular cylinder.

Coordination with Plumbing Components

In addition to the fuel lines, the Fuel Manifold also interacts with various plumbing components such as filters, regulators, and sensors. These components work in tandem to maintain the integrity and consistency of the fuel supply. For instance, fuel filters ensure that contaminants are removed before the fuel reaches the manifold, while regulators maintain the necessary pressure levels. Sensors monitor the fuel flow and pressure, providing feedback to the engine control unit (ECU) for real-time adjustments.

Enhanced Fuel Delivery

By centralizing the fuel distribution process, the 3922117 Fuel Manifold enhances the overall efficiency of the fuel delivery system. It allows for more precise control over fuel metering, which is essential for modern engines that rely on fuel injection technology. This precision contributes to better fuel economy, reduced emissions, and improved engine performance.

Simplified Maintenance

The design of the Fuel Manifold also simplifies maintenance and troubleshooting. Since it acts as a central point for fuel distribution, any issues with fuel delivery can often be traced back to this component. This makes it easier for engineers and mechanics to diagnose problems, perform repairs, and ensure that the fuel system operates within specified parameters.

Conclusion

In summary, the 3922117 Fuel Manifold plays a significant role in the fuel delivery system by efficiently distributing fuel to the injectors, interacting with various plumbing components, and enhancing overall engine performance. Its robust construction, precise engineering, and compatibility with Cummins engines make it a reliable choice for heavy-duty truck applications.

-

Limpert, Rudolf. Brake Design and Safety, Third Edition. SAE International, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.