This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

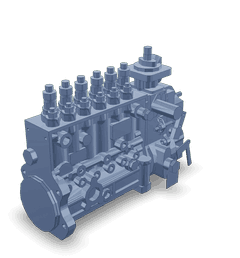

The Cummins 4988760 Fuel Injection Pump is a critical component designed for heavy-duty trucks. It ensures precise fuel delivery to the engine’s combustion chambers, contributing to optimal performance, fuel economy, and emissions control. This part is integral to the efficient operation of diesel engines.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump pressurizes and delivers fuel to the engine’s injectors. It draws fuel from the tank, pressurizes it, and distributes it to the injectors, which spray it into the combustion chambers 1. In diesel engines, the fuel injection pump ensures fuel is delivered at the correct pressure and timing for efficient combustion.

There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems use physical components and cam-driven mechanisms to control fuel delivery. Electronic systems employ sensors and electronic control units (ECUs) for more precise management of fuel injection, offering better performance and emissions control 2.

Role of the Cummins 4988760 Fuel Injection Pump in Truck Operation

The Cummins 4988760 Fuel Injection Pump is engineered to enhance heavy-duty truck operation. It ensures fuel is delivered with the necessary pressure and timing, contributing to overall engine performance. By providing consistent and precise fuel delivery, this part helps maintain engine power, improve fuel efficiency, and reduce emissions 3.

Key Features of the Cummins 4988760 Fuel Injection Pump

The Cummins 4988760 Fuel Injection Pump features high-quality materials for durability under demanding conditions. It includes advanced technological aspects such as precise fuel metering and robust construction, contributing to its efficiency and longevity 4.

Benefits of Using the Cummins 4988760 Fuel Injection Pump

Utilizing the Cummins 4988760 Fuel Injection Pump offers several advantages:

- Improved fuel economy due to efficient fuel delivery.

- Enhanced engine power resulting from optimal combustion.

- Reduced emissions thanks to precise fuel control.

- Increased durability owing to its robust construction.

These benefits make it a valuable component for heavy-duty truck applications.

Troubleshooting Common Issues with Fuel Injection Pumps

Identifying and addressing common problems with fuel injection pumps is crucial for maintaining engine performance. Symptoms of malfunction may include rough idling, decreased power, or increased emissions. Diagnostic procedures often involve checking fuel pressure, inspecting injectors, and assessing the pump’s mechanical or electronic components. Potential solutions range from cleaning or replacing injectors to repairing or replacing the pump itself.

Maintenance Tips for Fuel Injection Pumps

Routine maintenance is key to ensuring the longevity and optimal performance of the Cummins 4988760 Fuel Injection Pump. This includes regular inspections for wear or damage, cleaning procedures to remove contaminants, and adhering to recommended replacement intervals for key components. Proper maintenance helps prevent issues and ensures consistent engine performance.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industries. The company offers a comprehensive portfolio of products, including engines, filtration, emissions solutions, and power systems, all designed to meet the demanding needs of various applications.

Compatibility and Integration with Cummins Engines

The Cummins 4988760 Fuel Injection Pump is designed to integrate seamlessly with various Cummins engines, ensuring optimal performance and reliability. This part is particularly compatible with the 6C8.3 engine, where it plays a crucial role in the fuel delivery system. The 6C8.3 engine is known for its robust construction and efficiency, making it a popular choice in various applications.

In the context of the 6C8.3 engine, the 4988760 Fuel Injection Pump is engineered to deliver precise fuel metering, which is essential for maintaining engine performance and fuel efficiency. The pump’s design allows it to handle the specific demands of the 6C8.3 engine, ensuring that fuel is delivered at the correct pressure and timing for optimal combustion.

Additionally, the 4988760 Fuel Injection Pump is also compatible with other Cummins engines within the same engine family. This compatibility ensures that users can maintain a consistent and reliable fuel delivery system across different engine models, simplifying maintenance and part replacement processes.

The integration of the 4988760 Fuel Injection Pump with these engines is a testament to Cummins’ commitment to quality and performance. By ensuring that this part fits well with the 6C8.3 and other compatible engines, Cummins provides users with a reliable and efficient fuel delivery solution.

Role of the Cummins 4988760 Fuel Injection Pump in Engine Systems

The Cummins 4988760 Fuel Injection Pump is an integral component in the fuel delivery system of an engine, ensuring precise and efficient fuel distribution. This pump operates in conjunction with several other components to maintain optimal engine performance.

Interaction with the Fuel System

-

Fuel Tank: The pump draws fuel from the tank, where it is stored under pressure. This pressurized fuel is then directed towards the injection system.

-

Fuel Filter: Before reaching the pump, fuel passes through a filter that removes impurities. This ensures that only clean fuel enters the pump, preventing damage and ensuring efficient operation.

-

Fuel Lines: The pump is connected to fuel lines that transport fuel from the tank to the pump and from the pump to the injectors. These lines must be robust and leak-free to maintain consistent fuel pressure.

Coordination with Engine Components

-

Injectors: The pump delivers pressurized fuel to the injectors, which spray atomized fuel into the combustion chambers. This precise delivery is essential for achieving the correct air-fuel mixture, which is vital for combustion efficiency.

-

Engine Control Unit (ECU): The ECU monitors various engine parameters and adjusts the fuel injection timing and quantity accordingly. The pump must respond accurately to these signals to ensure optimal fuel delivery.

-

Camshaft and Crankshaft Sensors: These sensors provide data on engine speed and position, allowing the ECU to make real-time adjustments to the fuel injection process. The pump must operate in sync with these sensors to maintain engine performance.

-

Throttle Position Sensor: This sensor detects the position of the throttle and sends this information to the ECU. The pump adjusts fuel delivery based on throttle input, ensuring that the engine receives the appropriate amount of fuel under varying load conditions.

Maintenance and Performance

Regular maintenance of the fuel injection pump, including checks for leaks, proper fuel pressure, and clean fuel lines, is essential. Ensuring that the pump operates within specified parameters contributes to overall engine efficiency, reduced emissions, and prolonged engine life.

Conclusion

The Cummins 4988760 Fuel Injection Pump is a vital component in the operation of heavy-duty trucks, ensuring precise fuel delivery for optimal engine performance. Its compatibility with various Cummins engines, coupled with its robust design and advanced features, makes it a reliable choice for maintaining engine efficiency and longevity. Regular maintenance and proper troubleshooting are essential for maximizing the benefits of this part.

-

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Goodnight, Nicholas, and Kirk VanGelder. Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning, 2019.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Han, Zhiyu. Simulation and Optimization of Internal Combustion Engines. SAE International, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.