This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

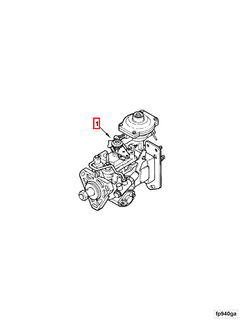

The Cummins 3975384 Fuel Injection Pump is a critical component in the fuel delivery system of commercial trucks. It ensures that fuel is delivered to the engine cylinders at precise timing and pressure, which is essential for efficient and reliable engine operation. This pump is integral to the performance and efficiency of diesel engines used in heavy-duty applications.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers. It operates by pressurizing fuel and injecting it into the cylinders at specific intervals, which are determined by the engine’s operational requirements. In diesel engines, the fuel injection pump plays a significant role by ensuring that fuel is delivered at high pressure to facilitate proper atomization and combustion. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, whereas electronic systems use sensors and computer controls to manage fuel injection more precisely 1.

Purpose of the Cummins 3975384 Fuel Injection Pump

The Cummins 3975384 Fuel Injection Pump is designed to deliver fuel to the engine cylinders with exact timing and pressure. This precision ensures optimal combustion, which directly influences the engine’s performance and fuel efficiency. By maintaining consistent fuel delivery, the pump helps in achieving smooth engine operation and reducing emissions.

Key Features

The Cummins 3975384 Fuel Injection Pump is characterized by its robust design and the use of high-quality materials, which contribute to its durability and reliability. It incorporates advanced technological features such as precise metering and high-pressure delivery capabilities. These features ensure that the pump can handle the demanding conditions of commercial truck operations while providing consistent performance.

Benefits

The Cummins 3975384 Fuel Injection Pump offers several benefits, including improved fuel efficiency, enhanced engine performance, and increased reliability. By ensuring that fuel is delivered at the correct pressure and timing, the pump helps in maximizing engine efficiency and reducing fuel consumption. Additionally, its reliable operation contributes to the overall durability and performance of the engine 2.

Installation and Integration

Proper installation of the Cummins 3975384 Fuel Injection Pump is crucial for ensuring its effective operation within the engine system. This involves careful alignment and secure mounting to prevent leaks and ensure stable operation. Integration may require adjustments to the engine’s fuel system to accommodate the pump’s specifications and ensure compatibility with other components.

Troubleshooting Common Issues

Common issues with fuel injection pumps can include leaks, inconsistent fuel delivery, and pump failure. Diagnosing these problems often involves checking for visible signs of leakage, testing fuel pressure, and inspecting electrical connections in electronic systems. Solutions may range from simple repairs, such as tightening connections or replacing seals, to more complex tasks like pump replacement or recalibration.

Maintenance Tips

Regular maintenance of the Cummins 3975384 Fuel Injection Pump is essential for ensuring its longevity and optimal performance. This includes routine cleaning to remove any contaminants, regular inspection for wear and tear, and scheduled replacement of wear parts such as seals and gaskets. Adhering to manufacturer-recommended maintenance schedules can help prevent unexpected failures and extend the pump’s service life.

Performance Enhancements

For those looking to enhance the performance of their Cummins 3975384 Fuel Injection Pump, several upgrades and modifications are available. These can include tuning the injection timing for better efficiency, installing high-flow injectors, or adding aftermarket components that improve fuel delivery. Such enhancements can lead to increased engine power and efficiency, provided they are implemented correctly and within the pump’s operational limits.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines and components. The company’s extensive product range and commitment to innovation have made it a preferred choice for commercial vehicle manufacturers and operators worldwide.

Cummins Fuel Injection Pump 3975384 Compatibility

The Cummins Fuel Injection Pump part number 3975384 is designed to integrate seamlessly with a variety of engine models, ensuring optimal performance and reliability. This part is engineered to meet the stringent demands of heavy-duty applications, providing precise fuel delivery and enhancing overall engine efficiency.

Engine Compatibility

The 3975384 fuel injection pump is specifically tailored to fit the following Cummins engines:

- 6B5.9: This engine model benefits from the advanced features of the 3975384 pump, which includes robust construction and precise fuel metering capabilities. The pump’s design ensures that it can handle the high-pressure requirements of the 6B5.9 engine, contributing to its durability and performance.

The compatibility of the 3975384 fuel injection pump with these engines underscores Cummins’ commitment to providing reliable and high-performing components for their diesel engines. This ensures that users can expect consistent and efficient operation, even under demanding conditions.

Role of Part 3975384 Fuel Injection Pump in Engine Systems

The part 3975384 Fuel Injection Pump is integral to the operation of modern engine systems, ensuring efficient fuel delivery and combustion. This component works in concert with several other key components to optimize engine performance.

Integration with the Fuel System

-

Fuel Pump: The fuel injection pump relies on the fuel pump to deliver fuel from the tank to the injection system. The fuel pump pressurizes the fuel, which is then sent to the injection pump for precise metering and delivery.

-

Fuel Filter: Before reaching the injection pump, fuel passes through the fuel filter. This ensures that any contaminants are removed, protecting the sensitive components within the injection pump from damage.

-

Fuel Injectors: Once the fuel is pressurized and filtered, the injection pump distributes it to the fuel injectors. These injectors spray atomized fuel into the combustion chamber at precise moments, dictated by the engine’s control unit.

Interaction with Engine Control Systems

-

Engine Control Unit (ECU): The ECU communicates with the fuel injection pump to regulate fuel delivery based on various parameters such as engine load, speed, and temperature. This ensures optimal fuel efficiency and performance.

-

Sensors: Multiple sensors, including the mass airflow sensor, oxygen sensor, and throttle position sensor, provide data to the ECU. This information is used to fine-tune the operation of the fuel injection pump, ensuring precise fuel delivery under all operating conditions.

Contribution to Combustion Efficiency

-

Combustion Chamber: The atomized fuel delivered by the injection pump mixes more effectively with air in the combustion chamber, leading to more complete and efficient combustion. This results in better power output and reduced emissions.

-

Exhaust System: Efficient combustion facilitated by the fuel injection pump leads to cleaner exhaust emissions. This is particularly important for meeting environmental regulations and maintaining the overall health of the engine.

Conclusion

In summary, the Cummins 3975384 Fuel Injection Pump is a key component that ensures the precise delivery of fuel, working in harmony with other engine systems to enhance performance, efficiency, and emissions control. Its robust design, advanced features, and compatibility with various Cummins engines make it a reliable choice for heavy-duty applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.