This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

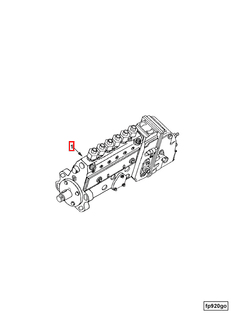

The Cummins 3932477 Fuel Injection Pump is a critical component in the operation of commercial trucks. It is designed to deliver precise amounts of fuel to the engine, ensuring efficient combustion and optimal performance. This pump is integral to the functionality of diesel engines, particularly in heavy-duty applications where reliability and efficiency are paramount 2.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that pressurizes and delivers fuel to the engine’s combustion chambers. In diesel engines, this process is crucial for efficient fuel combustion. Fuel injection pumps can be mechanical or electronic. Mechanical pumps use engine-driven components to meter and deliver fuel, while electronic systems utilize sensors and electronic control units (ECUs) to manage fuel delivery more precisely. The transition from mechanical to electronic systems has enhanced fuel efficiency, reduced emissions, and improved engine performance 1.

Purpose and Function of the 3932477 Fuel Injection Pump

The Cummins 3932477 Fuel Injection Pump plays a role in the operation of a truck by delivering fuel to the engine under high pressure. This ensures that the fuel atomizes properly within the combustion chamber, leading to efficient combustion. The pump’s precise fuel delivery helps maintain engine performance, reduce emissions, and enhance fuel economy 4.

Key Features

The Cummins 3932477 Fuel Injection Pump is characterized by its robust design and precise engineering. Key features include a durable housing, high-quality plungers and barrels, and advanced metering components. These elements work together to ensure consistent fuel delivery and reliable operation. The pump’s design also incorporates features that reduce noise and vibration, contributing to a smoother engine operation 3.

Benefits of Using the 3932477 Fuel Injection Pump

Using the Cummins 3932477 Fuel Injection Pump offers several advantages. It contributes to improved fuel efficiency by ensuring precise fuel delivery. This results in better engine performance and reduced fuel consumption. Additionally, the pump’s reliable operation enhances the overall durability and longevity of the engine. Its design also helps in reducing emissions, making it an environmentally friendly choice for commercial truck applications 2.

Common Issues and Troubleshooting

Common issues with the Cummins 3932477 Fuel Injection Pump may include fuel delivery inconsistencies, leaks, or pump wear. Troubleshooting steps involve inspecting the pump for signs of wear or damage, checking fuel lines for leaks, and ensuring that the pump is properly lubricated. Regular maintenance and timely replacement of worn components can prevent many issues. If problems persist, consulting a professional technician is recommended 3.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and optimal performance of the Cummins 3932477 Fuel Injection Pump. This includes periodic inspection for wear and tear, cleaning fuel lines and filters to prevent contamination, and replacing components as needed. Adhering to the manufacturer’s maintenance schedule will help maintain the pump’s efficiency and reliability 3.

Integration with Engine Management Systems

The Cummins 3932477 Fuel Injection Pump is designed to integrate seamlessly with modern engine management systems. It works in conjunction with electronic control units (ECUs) to optimize fuel delivery based on engine load, speed, and other operating conditions. This integration enhances engine performance, fuel efficiency, and emissions control 4.

Historical Development and Technological Advancements

The evolution of fuel injection technology has seen significant advancements over the years. Early mechanical pumps have given way to more sophisticated electronic systems. The development of the Cummins 3932477 Fuel Injection Pump reflects these technological improvements, offering enhanced precision, efficiency, and reliability in fuel delivery 1.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong commitment to innovation and quality, Cummins has played a significant role in the automotive and heavy-duty truck industries. The company’s fuel injection systems, including the 3932477 Fuel Injection Pump, are a testament to its dedication to advancing engine technology and providing reliable, high-performance solutions for commercial applications 2.

Compatibility and Performance

Engine Compatibility

- 6B5.9 Engine Series: The Cummins 3932477 Fuel Injection Pump is specifically designed to fit the 6B5.9 engine series, enhancing power output and efficiency 3.

- Other Cummins Engines: This part is also compatible with other Cummins engines that share similar design and operational parameters 3.

Performance and Reliability

- Precision Engineering: Ensures accurate fuel metering, crucial for maintaining engine performance and fuel efficiency 2.

- Durability: Designed to withstand heavy-duty operations, ensuring a long service life 3.

- Ease of Installation: Allows for quick and straightforward integration with the engine, minimizing downtime 3.

Application Scenarios

- Heavy-Duty Vehicles: Ideal for applications such as construction, mining, and transportation 3.

- Industrial Machinery: Suitable for various industrial machinery that relies on diesel engines 3.

Maintenance Considerations

- Regular Inspections: Recommended to maintain performance, including checking for leaks and ensuring proper fuel flow 3.

- Professional Servicing: Advised for comprehensive maintenance to identify and address potential issues promptly 3.

Role in Engine Systems

The Cummins 3932477 Fuel Injection Pump is an integral component in the fuel delivery system of an engine. It works in concert with several other components to ensure optimal engine performance. The pump pressurizes the fuel to the required levels before it is injected into the engine’s combustion chambers. It is synchronized with the engine’s timing system to ensure that fuel delivery is perfectly timed with the piston’s movements. Additionally, the pump interacts with the fuel filter to ensure that any contaminants are removed from the fuel before it reaches the injectors. The Engine Control Unit (ECU) monitors various parameters such as engine load, speed, and temperature to adjust the fuel delivery rate via the Fuel Injection Pump. This ensures that the engine operates efficiently under varying conditions 4.

Conclusion

The Cummins 3932477 Fuel Injection Pump is a vital component for ensuring efficient and reliable operation of diesel engines in commercial trucks and industrial machinery. Its precise engineering, durability, and compatibility with various engine models make it a preferred choice for heavy-duty applications. Regular maintenance and proper integration with engine management systems further enhance its performance and longevity.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ ↩ -

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ ↩ ↩ ↩ -

Cummins Inc. (n.d.). Service Manual (4388774). QSB4.5 CM2250 B131.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.