This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

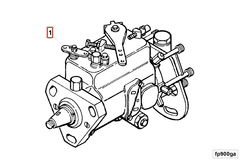

The Cummins 3915582 Fuel Injection Pump is a critical component in the operation of commercial trucks, especially those equipped with Cummins diesel engines. This pump ensures that the engine receives the precise amount of fuel needed for optimal performance. Its design and functionality are tailored to meet the demanding requirements of heavy-duty applications, contributing to efficient and reliable engine operation 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump pressurizes and delivers fuel to the engine cylinders in a diesel engine. It operates based on the principle of high-pressure fuel delivery, which ensures efficient combustion and power generation. The pump’s role is to meter the fuel, control the injection timing, and deliver it at the correct pressure to the injectors. This precise fuel delivery is essential for achieving the desired engine performance, fuel efficiency, and emissions control 2.

Purpose of the Cummins 3915582 Fuel Injection Pump

The Cummins 3915582 Fuel Injection Pump is designed to enhance the operation of trucks by providing accurate and consistent fuel delivery to the engine. It contributes to engine performance by ensuring that the fuel is injected at the optimal time and pressure, which helps in achieving efficient combustion. This results in improved fuel efficiency, as the engine can operate more effectively with the right fuel-air mixture. Additionally, the pump aids in emissions control by promoting cleaner combustion, which is vital for meeting environmental regulations. Its role in the fuel system is integral to the overall performance and reliability of the truck 3.

Key Features

The Cummins 3915582 Fuel Injection Pump boasts several key features that enhance its performance and reliability. Its design incorporates high-quality materials that are resistant to wear and corrosion, ensuring durability in harsh operating conditions. The pump features precise engineering that allows for accurate fuel metering and injection timing. Additionally, it may include technological advancements such as electronic controls for fine-tuning fuel delivery, which can further optimize engine performance and efficiency.

Benefits

Using the Cummins 3915582 Fuel Injection Pump offers several benefits. One of the primary advantages is improved fuel efficiency, as the pump ensures that the engine receives the exact amount of fuel needed for combustion. This not only saves on fuel costs but also reduces the environmental impact by lowering fuel consumption. Enhanced engine performance is another benefit, as the precise fuel delivery contributes to smoother operation and increased power output. Additionally, the pump helps in reducing emissions by promoting efficient combustion, which is crucial for compliance with environmental regulations. The durability of the pump ensures long-term reliability, reducing the need for frequent replacements and maintenance.

Installation and Integration

Proper installation and integration of the Cummins 3915582 Fuel Injection Pump into a truck’s fuel system are vital for optimal performance. It is important to follow the manufacturer’s guidelines to ensure compatibility with the specific engine model. Correct installation involves securing the pump in place, connecting it to the fuel lines, and ensuring that all connections are tight and leak-free. This step is critical to prevent fuel leaks and ensure that the pump operates efficiently. Additionally, it is important to verify that the pump is properly aligned and that all electrical connections, if any, are correctly made.

Troubleshooting and Maintenance

To ensure the longevity and reliable operation of the Cummins 3915582 Fuel Injection Pump, regular maintenance and troubleshooting are necessary. Common issues may include fuel leaks, inconsistent fuel delivery, or pump failure. Diagnostic procedures should be followed to identify the root cause of any problems. This may involve checking for worn-out components, ensuring proper fuel line connections, and verifying the pump’s electrical connections. Regular maintenance practices, such as cleaning the pump and replacing worn-out parts, can help prevent issues and ensure consistent performance.

Performance Optimization

Optimizing the performance of the Cummins 3915582 Fuel Injection Pump can be achieved through various techniques. Tuning options may include adjusting the injection timing and pressure to match the specific requirements of the engine. Using high-quality fuel is also important, as it ensures clean and efficient combustion. Environmental factors, such as temperature and altitude, can impact pump performance, so it is important to consider these when operating in different conditions. Regular monitoring and adjustments can help maintain optimal performance.

Safety Considerations

When working with the Cummins 3915582 Fuel Injection Pump, several safety considerations should be kept in mind. Proper handling of fuel is crucial to prevent spills and fires. It is important to follow safety protocols when performing maintenance or repairs, including wearing appropriate personal protective equipment. Adhering to maintenance schedules ensures that the pump operates reliably and reduces the risk of unexpected failures. Awareness of potential hazards, such as high-pressure fuel lines and electrical components, is essential to ensure a safe working environment.

Cummins Corporation

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its innovative and high-quality products. The company has a long history of providing reliable and efficient engine solutions, including fuel injection pumps. Cummins is committed to continuous innovation, ensuring that its products meet the evolving needs of the industry. The reputation of Cummins is built on its dedication to quality, customer satisfaction, and environmental responsibility, making it a trusted name in the commercial truck sector.

Role of Part 3915582 Fuel Injection Pump in Engine Systems

The Part 3915582 Fuel Injection Pump is integral to the efficient operation of engine systems, working in concert with several key components to ensure optimal performance.

Integration with Base Fuel Pump

The Base Fuel Pump serves as the initial stage in the fuel delivery process, drawing fuel from the tank and delivering it to the fuel injection pump. The Part 3915582 Fuel Injection Pump then takes over, pressurizing the fuel to the required levels for injection into the engine cylinders. This pressurized fuel is essential for achieving the precise fuel-air mixture needed for combustion.

Coordination with Fuel Injectors

Once pressurized by the fuel injection pump, the fuel is delivered to the Fuel Injectors. These injectors spray the fuel into the combustion chamber at the exact moment required for efficient burning. The timing and pressure provided by the fuel injection pump are vital for the injectors to perform their function accurately.

Interaction with Engine Control Unit (ECU)

The Engine Control Unit (ECU) monitors various parameters such as engine speed, load, and temperature to determine the optimal fuel delivery requirements. It sends signals to the Part 3915582 Fuel Injection Pump to adjust the fuel pressure and delivery rate accordingly, ensuring that the engine operates within its performance and emissions standards.

Synergy with Fuel Rail

The pressurized fuel from the injection pump is stored temporarily in the Fuel Rail before being distributed to the individual fuel injectors. The fuel injection pump maintains consistent pressure in the fuel rail, which is crucial for the injectors to operate effectively and deliver a uniform fuel spray.

Collaboration with Sensors

Various Sensors such as the Mass Air Flow (MAF) Sensor, Oxygen (O2) Sensor, and Throttle Position Sensor provide real-time data to the ECU. This data helps the ECU make precise adjustments to the fuel injection pump’s operation, ensuring that the fuel delivery is always optimized for the current driving conditions.

Conclusion

The Part 3915582 Fuel Injection Pump plays a significant role in the fuel delivery system by ensuring that fuel is pressurized and delivered at the right time and in the right quantity, working in harmony with other components to maintain engine efficiency and performance.

-

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology: Principles and Practice. Jones & Bartlett Learning.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.