This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

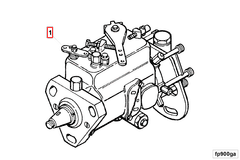

The Cummins 3913268 Fuel Injection Pump is a component designed for use in heavy-duty trucks. It plays a significant role in the fuel delivery system, ensuring that diesel fuel is delivered to the engine cylinders at the correct timing and pressure. This part is integral to the efficient operation of the truck’s diesel engine, contributing to its overall performance and reliability.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers. It operates by pressurizing fuel and injecting it into the cylinders at precise moments in the engine cycle. In diesel engines, the fuel injection pump is particularly important because it must deliver fuel at high pressure to ensure proper atomization and combustion. There are two main types of fuel injection pumps: mechanical and electronic. Mechanical pumps rely on engine-driven cams and springs to control fuel delivery, while electronic pumps use sensors and electronic controls for more precise fuel management 1.

Purpose of the Cummins 3913268 Fuel Injection Pump

The Cummins 3913268 Fuel Injection Pump is designed to deliver fuel to the engine cylinders with precision. It ensures that fuel is injected at the optimal timing and pressure, which is crucial for efficient combustion and engine performance. This part plays a role in maintaining the engine’s power output, fuel efficiency, and emissions levels.

Key Features

The Cummins 3913268 Fuel Injection Pump features a robust design that incorporates high-quality materials to withstand the demanding conditions of heavy-duty truck operation. It may include technological advancements such as precision machining and durable seals to enhance performance and longevity. The pump’s design ensures consistent fuel delivery and is engineered to integrate seamlessly with the truck’s fuel system.

Benefits

Using the Cummins 3913268 Fuel Injection Pump can lead to improved fuel efficiency, as it ensures that fuel is delivered to the engine in an optimal manner. This can result in enhanced engine performance, with smoother operation and increased power output. Additionally, the pump’s reliable design contributes to the overall durability and trustworthiness of the truck’s fuel system.

Common Issues and Troubleshooting

Common issues associated with the Cummins 3913268 Fuel Injection Pump may include leaks, erratic idling, or a decrease in power output. These issues can often be traced to worn components, contamination in the fuel, or improper installation. Troubleshooting may involve inspecting the pump for leaks, checking the fuel for contaminants, and ensuring that all connections are secure. Regular maintenance can help prevent many of these issues 2.

Maintenance Practices

To ensure the longevity and optimal performance of the Cummins 3913268 Fuel Injection Pump, regular maintenance is recommended. This includes inspecting the pump for signs of wear or damage, cleaning the fuel system to remove contaminants, and replacing worn components as necessary. Adhering to manufacturer-recommended maintenance intervals can help maintain the pump’s efficiency and reliability.

Integration with Engine Management Systems

The Cummins 3913268 Fuel Injection Pump is designed to integrate with modern engine management systems. It works in conjunction with sensors and electronic controls to optimize fuel delivery and engine performance. This integration allows for precise control over fuel injection timing and pressure, which can enhance engine efficiency and reduce emissions.

Environmental Impact

The Cummins 3913268 Fuel Injection Pump contributes to reduced emissions by ensuring precise fuel delivery, which can lead to more complete combustion and lower pollutant output. Its design and operation are in compliance with environmental regulations, reflecting Cummins’ commitment to producing components that minimize the environmental impact of heavy-duty trucks 3.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines and components. With a history of innovation and a reputation for quality, Cummins is dedicated to meeting the needs of its customers while also committing to sustainability and environmental stewardship. The company’s products, including the Cummins 3913268 Fuel Injection Pump, are a testament to its expertise in the diesel engine industry.

Cummins Fuel Injection Pump 3913268 Compatibility

The Cummins Fuel Injection Pump part number 3913268 is a critical component in the operation of several diesel engines, ensuring precise fuel delivery and efficient combustion. This part is designed to fit seamlessly with various engine models, enhancing performance and reliability.

Engine Compatibility

-

6B5.9 Series

- The 6B5.9 engine is part of the Cummins B Series engines, known for their robust design and durability. The 3913268 fuel injection pump is specifically engineered to integrate with the 6B5.9, providing the necessary fuel metering and injection timing for optimal engine performance.

-

Other Cummins Engines

- While the 6B5.9 is a notable example, the 3913268 fuel injection pump is also compatible with other Cummins engines within the B Series. This compatibility ensures that the pump can be used across multiple engine models, simplifying maintenance and repair processes.

Integration and Performance

-

Precision Engineering

- The 3913268 fuel injection pump is designed with precision engineering to match the specific requirements of the engines it fits. This ensures that the pump delivers fuel at the correct pressure and timing, which is crucial for maintaining engine efficiency and longevity.

-

Reliability and Durability

- Cummins is renowned for its high-quality components, and the 3913268 fuel injection pump is no exception. Built to withstand the rigors of heavy-duty operation, this pump is a reliable choice for maintaining the performance of Cummins engines.

Installation Considerations

-

Compatibility Check

- When installing the 3913268 fuel injection pump, it is essential to verify compatibility with the specific engine model. This ensures that the pump will function correctly and integrate smoothly with the engine’s fuel system.

-

Professional Installation

- Given the critical role of the fuel injection pump in engine operation, it is recommended to have the installation performed by a qualified technician. Proper installation is key to ensuring that the pump operates as intended and contributes to the overall performance of the engine.

Role of Part 3913268 Fuel Injection Pump in Engine Systems

The Part 3913268 Fuel Injection Pump is integral to the efficient operation of engine systems, working in concert with several key components to ensure optimal performance.

Interaction with the Base Fuel Pump

The Base Fuel Pump serves as the initial stage in the fuel delivery process, drawing fuel from the tank and delivering it to the Fuel Injection Pump. The Fuel Injection Pump then takes over, pressurizing the fuel to the levels required for injection into the engine’s combustion chambers. This pressurized fuel is essential for achieving the precise fuel-air mixture needed for efficient combustion.

Coordination with Fuel Injectors

Once pressurized by the Fuel Injection Pump, the fuel is distributed to the Fuel Injectors. These injectors spray the fuel into the combustion chambers at the exact moment required for combustion. The timing and pressure provided by the Fuel Injection Pump are vital for the injectors to function correctly, ensuring that the fuel is atomized properly for efficient burning.

Integration with the Engine Control Unit (ECU)

The Engine Control Unit (ECU) monitors various parameters such as engine speed, load, and temperature to determine the precise amount of fuel needed. It sends signals to the Fuel Injection Pump to adjust the fuel pressure and flow rate accordingly. This real-time adjustment ensures that the engine operates within its optimal performance range under varying conditions.

Contribution to the Common Rail System

In engines equipped with a Common Rail Fuel System, the Fuel Injection Pump plays a pivotal role in maintaining the high-pressure fuel reservoir. It ensures a consistent supply of pressurized fuel to the injectors, allowing for multiple injections per combustion cycle. This enhances combustion efficiency and reduces emissions.

Support for Turbocharging

In turbocharged engines, the Fuel Injection Pump must deliver fuel at even higher pressures to match the increased air density provided by the turbocharger. This ensures that the fuel-air mixture remains optimal, supporting the engine’s heightened performance and power output.

Enhancement of Fuel Economy and Emissions

By precisely controlling the fuel delivery, the Fuel Injection Pump contributes to improved fuel economy and reduced emissions. The accurate metering of fuel ensures that minimal fuel is wasted, and combustion is as complete as possible, leading to lower exhaust emissions.

Conclusion

The Cummins 3913268 Fuel Injection Pump is a critical component in the operation of heavy-duty diesel engines, ensuring precise fuel delivery and efficient combustion. Its robust design, compatibility with various engine models, and integration with modern engine management systems make it a reliable choice for maintaining engine performance and efficiency. Regular maintenance and proper installation are essential to ensure the longevity and optimal performance of this part.

-

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Bosch, Robert GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩ -

Hilgers, Michael. Chassis and Axles. Springer Vieweg, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.