This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

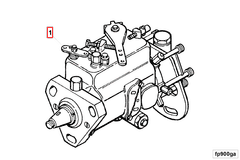

The Cummins 3912862 Fuel Injection Pump is a critical component for heavy-duty trucks, ensuring precise fuel delivery to the engine cylinders. This part is essential for maintaining engine performance and reliability 3.

Basic Concepts of Fuel Injection Pumps

Fuel injection pumps pressurize and deliver fuel to the engine’s combustion chambers. Diesel engines rely on these pumps to inject high-pressure fuel at precise moments in the engine cycle. There are two main types of fuel injection systems: mechanical and electronic. Mechanical systems use physical components, while electronic systems employ sensors and computer controls for more precise management of injection timing and quantity 2.

Purpose and Function of the 3912862 Fuel Injection Pump

This Cummins part ensures fuel is injected at the optimal time and pressure, crucial for efficient combustion and engine performance. It works with other engine components to maintain the correct fuel-air mixture, essential for power output and fuel economy 4.

Key Features

The 3912862 is characterized by its robust design and high-quality materials. It features precise engineering for accurate fuel delivery, durable construction for heavy-duty use, and compatibility with various Cummins engines 1.

Benefits of Using the 3912862 Fuel Injection Pump

Using this part improves fuel efficiency by ensuring optimal fuel delivery, leading to cost savings. It enhances engine performance through consistent and precise fuel injection, maintaining engine power and responsiveness. Its reliability ensures smooth and efficient engine operation under various conditions 3.

Installation and Integration

Proper installation of the 3912862 is crucial for optimal performance and compatibility with the truck’s engine system. Follow manufacturer guidelines, which may include specific prerequisites or steps to ensure correct integration into the engine’s fuel system. This involves checking alignment, securing connections, and verifying pump function 4.

Maintenance and Troubleshooting

Regular maintenance of the 3912862 is important for its longevity and efficiency. This includes routine checks for leaks, secure connections, and monitoring performance. Common issues like fuel delivery problems or pump malfunctions can often be addressed through troubleshooting steps such as checking for blockages, ensuring proper fuel pressure, and verifying electrical connections if applicable 1.

Performance Enhancements

The 3912862 significantly enhances overall engine performance by providing precise fuel delivery, contributing to increased power output and improved fuel economy. It also helps reduce emissions by ensuring more efficient fuel combustion, beneficial for both environmental and operational reasons 2.

Safety Considerations

When working with the 3912862, observe safety practices to prevent accidents and ensure safe operation. This includes wearing appropriate personal protective equipment, ensuring the engine is off and cool before work, and following all manufacturer safety guidelines. Proper handling and disposal of fuel and components are also critical to maintaining a safe working environment 3.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and fuel systems. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industries for producing reliable and high-performance products. The company’s commitment to innovation and quality is evident in its extensive product range, which includes the 3912862 Fuel Injection Pump 4.

Conclusion

The 3912862 Fuel Injection Pump is a vital component in the fuel delivery system of heavy-duty trucks. Its precise fuel delivery ensures optimal engine performance, reliability, and efficiency. Proper installation, regular maintenance, and adherence to safety practices are essential for maximizing the benefits of this part.

-

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩ ↩ -

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality, Elsevier, 2021.

↩ ↩ -

F. K. Sully, Motor Vehicle Mechanics Textbook, Fifth Edition, Heinemann Professional Publishing, 1998.

↩ ↩ ↩ -

Robert Bosch GmbH, Bosch Automotive Handbook 9th Edition, Robert Bosch GmbH, 2014.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.