This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3354617 Fuel Injection Pump is a vital component in the operation of commercial trucks, particularly those equipped with Cummins diesel engines. This pump plays a significant role in the fuel delivery system, ensuring that the engine receives the precise amount of fuel needed for optimal performance. Its efficient operation is essential for maintaining engine power, fuel efficiency, and emissions control.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers at the correct pressure and timing. In diesel engines, this pump is responsible for atomizing the fuel into a fine mist, which then mixes with air and ignites under compression. There are several types of fuel injection pumps, including inline, rotary, and common rail systems, each with its own set of applications and advantages. The Cummins 3354617 is an example of an inline fuel injection pump, designed specifically for use in heavy-duty diesel engines 1.

Purpose of the Cummins 3354617 Fuel Injection Pump

The Cummins 3354617 Fuel Injection Pump is engineered to deliver fuel to the engine’s injectors at the precise moment and pressure required for combustion. This ensures that the engine operates efficiently, with optimal power output and minimal emissions. By maintaining consistent fuel delivery, the pump contributes to the overall performance, fuel efficiency, and emissions control of the truck 2.

Key Features

The Cummins 3354617 Fuel Injection Pump is characterized by its robust design and high-quality construction materials. It features a durable housing, precision-machined components, and advanced sealing technologies that enhance its performance and longevity. Additionally, the pump incorporates unique attributes such as adjustable fuel delivery settings, which allow for fine-tuning to meet specific engine requirements.

Benefits

Utilizing the Cummins 3354617 Fuel Injection Pump offers several advantages. These include improved fuel economy due to precise fuel delivery, enhanced engine power resulting from optimal combustion, reduced emissions through efficient fuel atomization, and increased reliability thanks to its robust construction and advanced features.

Installation and Compatibility

Proper installation of the Cummins 3354617 Fuel Injection Pump is crucial for ensuring optimal performance. This involves following manufacturer guidelines, using the appropriate tools and equipment, and verifying compatibility with the specific Cummins engine model. Careful attention to these factors will help maintain the pump’s efficiency and longevity.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 3354617 Fuel Injection Pump is essential for ensuring its optimal performance and longevity. This includes regular inspections, cleaning, and lubrication of moving parts. Common troubleshooting tips for addressing issues such as fuel delivery problems, leaks, or performance declines involve checking for worn components, ensuring proper fuel filter maintenance, and verifying the integrity of fuel lines and connections.

Performance Enhancements

There are various performance enhancements and upgrades available for the Cummins 3354617 Fuel Injection Pump. These may include aftermarket options such as high-performance injectors, upgraded fuel lines, or tuning solutions that can further optimize fuel delivery and engine performance. Careful consideration of these enhancements can lead to improved overall truck performance.

Safety Considerations

When working with the Cummins 3354617 Fuel Injection Pump, it is important to observe safety considerations. This includes proper handling procedures, the use of appropriate safety equipment, and awareness of potential hazards such as high-pressure fuel lines and moving parts. Adhering to these safety guidelines will help prevent accidents and ensure a safe working environment.

Environmental Impact

The Cummins 3354617 Fuel Injection Pump plays a role in reducing emissions and promoting sustainable transportation practices. By ensuring precise fuel delivery and efficient combustion, the pump helps minimize the release of harmful pollutants into the atmosphere. This contributes to cleaner air and a reduced environmental footprint for commercial trucking operations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of diesel and natural gas engines, as well as related technologies. With a rich history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the diesel engine industry. The company’s product offerings include engines, filtration systems, emissions solutions, and power generation equipment, all designed to meet the demanding needs of commercial and industrial applications.

Cummins Fuel Injection Pump 3354617 Compatibility

The Cummins Fuel Injection Pump part number 3354617 is a critical component designed to work seamlessly with various engine models. This part is engineered to ensure optimal performance and reliability across different engine configurations.

Engine Compatibility

-

6C8.3 Engines

- The 3354617 fuel injection pump is specifically tailored to fit the 6C8.3 engine series. This engine is known for its robust performance and efficiency, making it a popular choice in various applications. The pump’s design ensures precise fuel delivery, enhancing the engine’s power output and fuel economy.

-

Other Cummins Engines

- While the primary focus is on the 6C8.3 engines, the 3354617 fuel injection pump is also compatible with other Cummins engine models. This versatility allows for broader application across different machinery and vehicles, ensuring that the pump can be used in various settings where Cummins engines are installed.

Installation and Integration

The installation of the 3354617 fuel injection pump is straightforward, designed to integrate easily with the engine’s existing fuel system. Proper installation is crucial for maintaining the engine’s performance and longevity. Technicians should follow the manufacturer’s guidelines to ensure the pump is correctly aligned and securely fastened.

Performance Benefits

-

Enhanced Fuel Efficiency

- The 3354617 fuel injection pump delivers fuel with high precision, which helps in achieving better fuel efficiency. This is particularly beneficial for engines operating under heavy loads or in demanding conditions.

-

Improved Power Output

- By ensuring that the engine receives the correct amount of fuel at the right time, the pump contributes to improved power output. This is essential for maintaining the engine’s performance and responsiveness.

-

Reliability and Durability

- Built with high-quality materials and advanced engineering, the 3354617 fuel injection pump is designed to withstand the rigors of continuous operation. This reliability ensures that the engine can operate smoothly over an extended period, reducing the need for frequent maintenance and repairs.

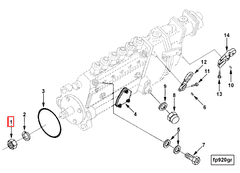

Role of Part 3354617 Fuel Injection Pump in Engine Systems

This part is an integral component in the fuel delivery system of an engine. It works in conjunction with several other components to ensure efficient and precise fuel delivery, which is essential for optimal engine performance.

Interaction with the Fuel Pump

The fuel pump is responsible for drawing fuel from the tank and delivering it to the fuel injection pump. The fuel injection pump, part 3354617, then takes this fuel and pressurizes it to the levels required for injection into the engine’s combustion chambers. This pressurized fuel is delivered through fuel lines to the injectors.

Coordination with Fuel Injectors

Fuel injectors are the final point in the fuel delivery system where pressurized fuel is sprayed into the engine’s cylinders. The fuel injection pump ensures that the fuel is delivered at the correct pressure and timing, allowing the injectors to atomize the fuel properly. This fine mist of fuel mixes with the air in the cylinders, creating an optimal air-fuel mixture for combustion.

Integration with the Engine Control Unit (ECU)

The Engine Control Unit (ECU) plays a significant role in managing the fuel injection process. It receives signals from various sensors, such as the oxygen sensor, throttle position sensor, and engine speed sensor. Based on these inputs, the ECU sends commands to the fuel injection pump to adjust the fuel delivery rate and pressure. This ensures that the engine operates efficiently under varying conditions, whether idling, cruising, or accelerating.

Synergy with the Air Intake System

The air intake system supplies the necessary air required for combustion. The fuel injection pump must work in harmony with the air intake system to maintain the correct air-fuel ratio. This balance is vital for maximizing engine power, fuel efficiency, and reducing emissions.

Relationship with the Exhaust System

The exhaust system is responsible for expelling the byproducts of combustion from the engine. Efficient fuel delivery by the fuel injection pump ensures complete combustion, which minimizes unburnt fuel and harmful emissions. This, in turn, reduces the workload on the catalytic converter and other components within the exhaust system.

Conclusion

The Cummins 3354617 Fuel Injection Pump is a key player in the engine’s fuel delivery system, working seamlessly with the fuel pump, fuel injectors, ECU, air intake system, and exhaust system to ensure optimal engine performance and efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.