This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

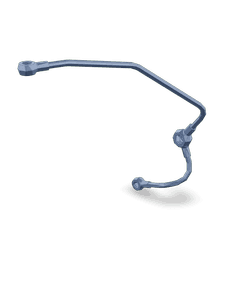

The Cummins 4002010 Fuel Drain Tube is a component designed for use in the fuel systems of heavy-duty trucks. Its purpose is to facilitate the drainage of fuel from the system, ensuring that any contaminants or water that may accumulate are effectively removed. This helps maintain the integrity and efficiency of the fuel system, contributing to the overall performance and reliability of the vehicle 3.

Basic Concepts of Fuel Drain Tubes

A fuel drain tube is a component within the fuel system that allows for the controlled release of fuel. Its function is to provide a pathway for the drainage of fuel, which is necessary for maintenance procedures such as fuel filter changes or system purging. The operation of a fuel drain tube ensures that fuel can be efficiently delivered to the engine while also allowing for the removal of any impurities that may have entered the system 1.

Purpose of the Cummins 4002010 Fuel Drain Tube

This Cummins part plays a specific role in the operation of a truck by enabling the drainage of fuel from the system. This is particularly important during the fuel filtration process, where contaminants and water are separated from the fuel. By providing a means to drain these impurities, the tube helps maintain the cleanliness of the fuel, which is vital for the efficient operation of the engine 3.

Key Features

The 4002010 is constructed from materials that offer durability and resistance to the corrosive effects of fuel. Its design includes features that enhance its performance, such as a secure fitting mechanism that ensures a tight seal within the fuel system. These attributes contribute to the tube’s ability to withstand the demands of heavy-duty truck applications 2.

Benefits of Using the Cummins 4002010 Fuel Drain Tube

Utilizing this part offers several advantages. It contributes to improved fuel system efficiency by ensuring that the fuel delivered to the engine is free from contaminants. Additionally, the tube’s design reduces the need for frequent maintenance, as it is built to last and perform under demanding conditions. The enhanced reliability of the fuel system is another benefit, as the tube plays a role in maintaining the system’s integrity over time 3.

Installation Considerations

When installing this Cummins part, it is important to follow the manufacturer’s guidelines to ensure a secure and effective fit. This may involve preparing the installation site, using the appropriate tools, and verifying that the tube is correctly positioned within the fuel system. Proper installation is key to the tube’s performance and the overall efficiency of the fuel system 1.

Troubleshooting Common Issues

Common problems associated with fuel drain tubes can include leaks or blockages. To address these issues, it is important to conduct a thorough inspection of the tube and the surrounding components. If a leak is detected, the tube may need to be replaced or repaired. Blockages can often be cleared by flushing the system or replacing the filter. Regular maintenance can help prevent these issues from occurring 2.

Maintenance Tips

To prolong the lifespan of the 4002010, regular maintenance practices should be followed. This includes inspecting the tube for signs of wear or damage, cleaning the area around the tube to prevent debris accumulation, and replacing the tube according to the manufacturer’s recommendations or when signs of degradation are observed 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the automotive and heavy-duty truck industry. The company’s product range is designed to meet the demanding requirements of various applications, ensuring reliability and performance 3.

Cummins Engine Compatibility with Fuel Drain Tube Part 4002010

The Cummins-manufactured Fuel Drain Tube part number 4002010 is designed to fit seamlessly into the fuel systems of several Cummins engine models. This part is crucial for maintaining the efficiency and reliability of the engines by ensuring proper fuel drainage.

ISL CM554 and QSL9 CM554 Engines

The ISL CM554 and QSL9 CM554 engines are part of Cummins’ robust lineup, known for their durability and performance. The Fuel Drain Tube part 4002010 is specifically engineered to integrate with these engines, facilitating the removal of water and sediment from the fuel system. This integration is vital for preventing engine damage and ensuring optimal performance 3.

Installation and Functionality

When installed in the ISL CM554 and QSL9 CM554 engines, the Fuel Drain Tube part 4002010 connects to the fuel system at a designated point, allowing for the easy drainage of contaminants. This part is designed to withstand the high pressures and temperatures typical of these engines, ensuring a reliable and long-lasting solution 1.

Importance of Proper Installation

Proper installation of the Fuel Drain Tube part 4002010 is essential for the longevity and efficiency of the ISL CM554 and QSL9 CM554 engines. It is recommended to follow Cummins’ guidelines for installation to ensure that the part functions as intended and to avoid potential issues that could arise from improper fitting 2.

Role of Part 4002010 Fuel Drain Tube in Engine Systems

The part 4002010 Fuel Drain Tube is an essential component in the maintenance and operation of various engine systems, particularly those involving fuel injection and fuel pumping mechanisms.

In systems equipped with a Fuel Injection Pump, the Fuel Drain Tube facilitates the removal of any contaminants or water that may have accumulated within the fuel lines. This ensures that only clean fuel is delivered to the injectors, thereby maintaining the efficiency and reliability of the fuel injection process.

When integrated with a Fuel Pump, the Fuel Drain Tube allows for the periodic draining of the fuel tank. This is particularly important in preventing the build-up of sediment and water, which can impair the pump’s performance and lead to inefficient fuel delivery.

In systems where a general Pump is used for fuel transfer, the Fuel Drain Tube provides a means to purge the system of any impurities. This is vital for maintaining the pump’s longevity and ensuring consistent fuel flow.

For engines utilizing Fuel Injection systems, the Fuel Drain Tube plays a supportive role in keeping the injection lines free from debris. This contributes to the precise delivery of fuel to the combustion chambers, enhancing overall engine performance and fuel economy.

Overall, the Fuel Drain Tube is a key component in ensuring the cleanliness and integrity of the fuel system, directly influencing the operational efficiency of the engine 3.

Conclusion

The Cummins 4002010 Fuel Drain Tube is a vital component in the fuel systems of heavy-duty trucks, ensuring the removal of contaminants and water to maintain engine efficiency and reliability. Its durable construction, ease of installation, and role in various engine systems underscore its importance in the maintenance and operation of these vehicles 3.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.