This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

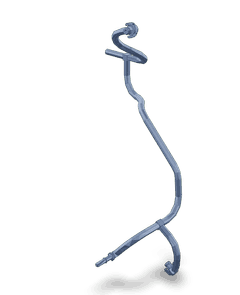

The Cummins 3964119 Fuel Drain Tube is a critical component in the fuel systems of heavy-duty trucks. It is designed to facilitate the draining of fuel and water from the fuel tank, ensuring that the fuel delivered to the engine is clean and free from contaminants. This helps maintain the efficiency and reliability of the truck’s fuel system 1.

Purpose and Function

This Cummins part plays a significant role in the fuel system by allowing for the periodic removal of fuel and water that may accumulate in the fuel tank. Water can enter the fuel system through condensation or from impurities in the fuel itself. The presence of water in the fuel can lead to corrosion, reduced fuel efficiency, and potential damage to the engine. By providing a means to drain this water, the Fuel Drain Tube helps maintain the quality of the fuel and protects the engine from water-related issues 2.

Key Features

The 3964119 is constructed from durable materials that are resistant to the corrosive effects of fuel and water. It features a robust design that ensures reliable performance under the demanding conditions encountered in heavy-duty truck applications. The tube is equipped with secure connection points that facilitate easy integration into the truck’s fuel system. Additionally, its design includes features that enhance its durability and effectiveness in draining fuel and water 3.

Benefits

Incorporating this part into a truck’s fuel system offers several advantages. It contributes to improved fuel quality by allowing for the removal of water and contaminants, which can enhance engine performance and efficiency. By maintaining cleaner fuel, the risk of fuel system contamination is reduced, leading to fewer maintenance issues and extended engine longevity. The tube’s reliable design ensures consistent performance, supporting the overall reliability of the truck’s fuel system 4.

Installation and Usage

Proper installation of the Fuel Drain Tube is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure secure and proper integration into the fuel system. Regular usage of the drain tube, as part of routine maintenance, is recommended to prevent the accumulation of water and contaminants in the fuel tank. Following the recommended procedures for draining fuel will help maintain the efficiency and reliability of the truck’s fuel system.

Maintenance and Troubleshooting

To ensure the optimal performance of the Fuel Drain Tube, regular maintenance is advised. This includes periodic inspection of the tube for signs of wear or damage, and cleaning as necessary to remove any buildup that may affect its operation. Troubleshooting common issues, such as difficulty in draining fuel, may involve checking the connections for leaks or obstructions and ensuring the tube is properly installed. Adhering to these maintenance practices will help prolong the life of the Fuel Drain Tube and maintain its effectiveness.

Safety Considerations

When working with the Fuel Drain Tube, it is important to observe safety guidelines to protect against the hazards associated with fuel and its vapors. This includes ensuring proper ventilation when performing maintenance tasks to avoid the accumulation of flammable vapors. Additionally, handling the tube and fuel with care, following all safety precautions, will help prevent accidents and ensure a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and quality, Cummins has established a strong reputation in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its products, which are designed to deliver reliable performance and efficiency in demanding applications.

Compatibility

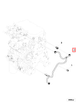

The Fuel Drain Tube, part number 3964119, is designed to fit seamlessly into various Cummins engine models. This component is integral for maintaining the efficiency and reliability of the engines by allowing the drainage of excess fuel and contaminants from the fuel system.

ISB/ISD6.7 CM2150 SN

The ISB/ISD6.7 CM2150 SN engines benefit from the precise fit and functionality of the 3964119 Fuel Drain Tube. This part ensures that any accumulated fuel or impurities are effectively removed, contributing to the engine’s overall performance and longevity.

ISBE CM800 and ISBE4 CM850

Similarly, the ISBE CM800 and ISBE4 CM850 engines are compatible with the 3964119 Fuel Drain Tube. This part is engineered to integrate smoothly with these models, providing a reliable solution for fuel system maintenance. By facilitating the drainage of unwanted substances, it helps in preserving the integrity of the fuel system and enhancing engine efficiency.

Role in Engine Systems

The Fuel Drain Tube (Part 3964119) is a vital component in the fuel system of an engine, facilitating the safe and efficient removal of fuel during maintenance or emergency situations. Its integration with various engine components ensures the system’s reliability and safety.

Integration with Overhaul Kit

When an engine undergoes an overhaul, the Fuel Drain Tube plays a significant role in the process. It is often included in the Overhaul Kit to ensure that the fuel system can be properly drained before disassembly. This prevents fuel spillage and contamination, maintaining a clean working environment and ensuring the safety of the mechanic.

Plumbing and Fuel System Compatibility

The Fuel Drain Tube is designed to interface seamlessly with the engine’s Plumbing system. It connects to the fuel tank and other fuel lines, allowing for the controlled release of fuel. This connection is vital for routine maintenance checks, such as verifying fuel quality or performing system purges. The tube’s design ensures a secure fit, preventing leaks and ensuring that the fuel system remains pressurized correctly.

Emergency Fuel Drain

In emergency situations, such as a fuel leak or system malfunction, the Fuel Drain Tube provides a quick and effective means to evacuate fuel from the system. This rapid drainage capability is essential for minimizing risks associated with fuel exposure, such as fires or explosions. The tube’s placement and design allow for easy access, enabling mechanics to act swiftly in critical scenarios.

Routine Maintenance

During routine maintenance, the Fuel Drain Tube is used to sample fuel for analysis. This helps in detecting contaminants or water in the fuel, which can lead to engine performance issues. By draining a small amount of fuel through the tube, mechanics can perform necessary tests and ensure the fuel system’s integrity.

Fuel System Integrity

The Fuel Drain Tube contributes to the overall integrity of the fuel system by allowing for periodic checks and maintenance. Its role in draining fuel ensures that the system remains free of debris and contaminants, which can otherwise lead to clogged fuel filters or injectors. This proactive approach to maintenance helps in extending the lifespan of the engine and ensuring optimal performance.

Conclusion

The Cummins 3964119 Fuel Drain Tube is an essential component for maintaining the efficiency and reliability of heavy-duty truck fuel systems. By facilitating the removal of water and contaminants, it ensures that the fuel delivered to the engine is clean, thereby enhancing engine performance and longevity. Proper installation, regular maintenance, and adherence to safety guidelines are crucial for the effective operation of this part. Its compatibility with various Cummins engine models further underscores its importance in the automotive industry.

-

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Hilgers, M. (2022). The Drivers Cab. Springer Vieweg.

↩ -

Van Gelder, K.T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Hilgers, M. (2023). Chassis and Axles. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.