3945707

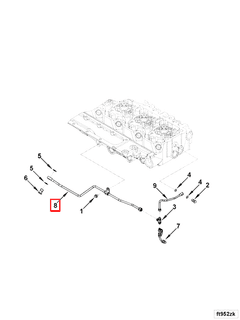

Fuel Drain Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3945707 Fuel Drain Tube is a specialized component used in the fuel systems of commercial trucks. It is designed to facilitate the removal of contaminants and water from the fuel prior to it reaching the engine, contributing to the efficiency and reliability of the vehicle’s power system 1.

Purpose and Function

This Cummins part allows for the periodic removal of sediment, water, and other impurities that may accumulate in the fuel tank. By providing a means to drain these contaminants, it helps maintain the purity of the fuel delivered to the engine, which is important for ensuring optimal combustion and preventing potential damage to engine components caused by impurities 2.

Key Features

The Fuel Drain Tube is constructed with materials resistant to the corrosive effects of diesel fuel and the contaminants it may contain. Its design is intended to be robust, ensuring it can withstand the pressures and temperatures within the fuel system. Features may include a secure fitting mechanism to prevent leaks and a durable construction that enhances its longevity in demanding operating conditions 3.

Benefits

The use of the 3945707 can lead to several advantages. It contributes to improved fuel quality by allowing for the removal of contaminants, which in turn can enhance engine performance. Additionally, by maintaining cleaner fuel, it may help reduce the frequency of maintenance required for the fuel system and engine, potentially leading to cost savings over time 4.

Installation and Integration

Proper installation of this part involves securing it to the fuel system in a manner that ensures a leak-free connection. It is designed to be compatible with various Cummins engines and integrates with other fuel system components to form a cohesive system for fuel delivery and contaminant management. Detailed instructions for installation should be followed to ensure correct placement and operation.

Maintenance and Troubleshooting

Regular maintenance of the Fuel Drain Tube includes periodic checks for leaks and the scheduled draining of contaminants from the fuel system. Common issues may involve blockages or leaks, which can often be resolved by cleaning or replacing the tube as necessary. Adherence to maintenance schedules can help prevent more serious problems and ensure the continued efficient operation of the fuel system.

Safety Considerations

When handling and maintaining the Fuel Drain Tube, it is important to observe safety guidelines to protect against potential hazards. This includes working in a well-ventilated area, wearing appropriate personal protective equipment, and following procedures to avoid spills and contact with fuel. Understanding the potential risks associated with fuel system components and taking steps to mitigate them is crucial for safe maintenance practices.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, and vehicle markets with a diverse product range that includes engines, filtration, emissions solutions, and more. The company’s focus on technological advancement and customer satisfaction has established it as a reputable name in the industry.

Conclusion

The Cummins 3945707 Fuel Drain Tube is a vital component in the maintenance and operation of several Cummins engine models. Its role in facilitating the drainage of fuel from the engine’s fuel system ensures that contaminants or water are removed, which is crucial for the engine’s longevity and performance. Proper installation, regular maintenance, and adherence to safety guidelines are essential for the efficient and safe operation of this part within the fuel system.

-

TK Garrett, K Newton, W Steeds, The Motor Vehicle, Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Kirk T Van Gelder, Fundamentals of Automotive Technology Principles and Practice, Jones Bartlett Learning, 2018.

↩ -

Gang Sheng, Vehicle Noise, Vibration and Sound Quality, SAE International, 2012.

↩ -

Paul Dempsey, Troubleshooting and Repairing Diesel Engines, McGraw-Hill, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.