This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Fuel Drain Tube, part number 3920889, is a component designed to facilitate the removal of contaminants and water from the fuel system of commercial trucks. Its primary function is to ensure that the engine receives clean fuel for optimal performance. Cummins, a well-established manufacturer in the commercial truck industry, produces this part with a focus on durability and efficiency.

Purpose and Function

The Fuel Drain Tube is integral to the fuel system, allowing for the periodic removal of water and contaminants that may accumulate in the fuel tank. By enabling the drainage of these impurities, the tube helps maintain the quality of the fuel delivered to the engine. Clean fuel is important for engine performance and longevity, as contaminants can lead to inefficient combustion and increased wear on engine components 1.

Key Features

This Cummins part is constructed from materials that offer durability and resistance to the corrosive effects of fuel and water. Its design ensures compatibility with Cummins engines, providing a reliable connection within the fuel system. The tube’s construction includes features that enhance its performance and reliability, such as a secure fitting mechanism that prevents leaks and ensures a consistent flow of clean fuel 2.

Benefits

Incorporating the Fuel Drain Tube into commercial truck fuel systems offers several advantages. It contributes to improved fuel quality by effectively removing contaminants, which in turn enhances engine efficiency. Additionally, by maintaining clean fuel, the tube can help reduce maintenance costs associated with engine wear and performance issues. Its use is associated with better overall truck performance and reliability 3.

Installation and Usage

Installing the Fuel Drain Tube involves connecting it to the appropriate points within the truck’s fuel system. Proper placement and secure connections are important to ensure optimal performance. Following the manufacturer’s guidelines during installation is recommended to maintain the integrity of the fuel system and ensure the tube functions as intended 4.

Maintenance and Troubleshooting

Regular maintenance of the Fuel Drain Tube includes checking for signs of wear or malfunction, such as leaks or blockages. Addressing these issues promptly can help ensure the longevity and efficient operation of the component. Routine checks and adhering to recommended maintenance schedules are important practices for maintaining the fuel drain tube’s performance.

Common Issues and Solutions

Common problems with Fuel Drain Tubes may include clogging due to accumulated contaminants or wear leading to leaks. Solutions to these issues involve regular draining of the fuel system to remove contaminants and inspecting the tube for signs of wear. Preventive measures, such as routine maintenance and timely replacements when necessary, are important to avoid these common issues.

Cummins Overview

Cummins Inc. has a long-standing reputation in the commercial truck industry for its commitment to quality and innovation in engine and component manufacturing. The company’s history is marked by a dedication to producing reliable and efficient products that meet the demanding requirements of commercial transportation. Cummins’ reputation is built on its consistent delivery of high-quality components, including the Fuel Drain Tube, which reflects the company’s standards for durability and performance.

Cummins Fuel Drain Tube Compatibility

The Cummins Fuel Drain Tube, part number 3920889, is compatible with a range of Cummins engines. Its design allows it to fit seamlessly into the fuel systems of these engines, ensuring efficient fuel management and reducing the risk of contamination.

Role of Fuel Drain Tube in Engine Systems

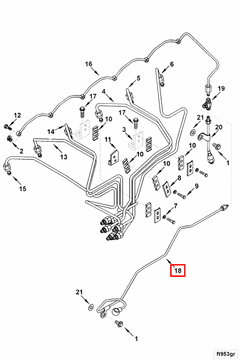

The Fuel Drain Tube (part 3920889) is an essential component in the fuel system of an engine, facilitating the safe and efficient management of fuel flow. It is strategically integrated within the fuel plumbing network to ensure that any excess or contaminated fuel can be effectively removed from the system.

In the context of fuel plumbing, the Fuel Drain Tube is positioned downstream of the fuel filter and upstream of the fuel injectors. Its primary function is to provide a controlled pathway for draining fuel, which is particularly important during maintenance procedures or when the fuel quality is compromised. This helps in preventing contaminants from reaching the fuel injectors and compromising engine performance.

Additionally, the Fuel Drain Tube interacts with the plumbing components such as fuel lines and connectors. It ensures that the drained fuel is directed away from the engine bay, minimizing the risk of fuel spills and enhancing safety during maintenance operations. The tube is designed to withstand the pressures and temperatures within the fuel system, ensuring reliable performance over time.

Overall, the integration of the Fuel Drain Tube within the fuel system enhances the efficiency and safety of fuel management, contributing to the overall reliability and performance of the engine.

Conclusion

The Cummins Fuel Drain Tube, part number 3920889, plays a significant role in maintaining the integrity and efficiency of the fuel system in commercial trucks. By facilitating the removal of contaminants and water from the fuel, it ensures that the engine receives clean fuel, which is critical for optimal performance and longevity. Its durable construction, compatibility with various Cummins engines, and the benefits it offers in terms of engine efficiency and reduced maintenance costs make it a valuable component in the fuel system. Regular maintenance and adherence to installation guidelines are important to maximize the performance and lifespan of this part.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013

↩ -

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010

↩ -

Chassis and Axles, Michael Hilgers, Springer Vieweg, 2023

↩ -

Modern Diesel Technology Preventive Maintenance and Inspection, John Dixon, Delmar Cengage Learning, 2010

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.