This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

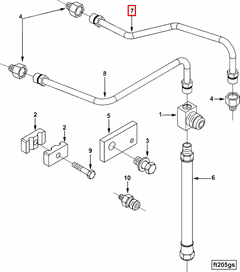

The Cummins Fuel Drain Tube, part number 3899526, is a component designed for use in commercial trucks. It serves a specific function within the fuel system, facilitating the safe and efficient draining of fuel for maintenance or emergency purposes. Cummins, a well-established manufacturer in the automotive industry, produces this part with a focus on reliability and performance 1.

Purpose and Function

This Cummins part is integral to the fuel system of a truck, providing a means to drain fuel when necessary. This can be for routine maintenance, such as filter changes, or in emergency situations where fuel needs to be removed quickly. The tube allows for controlled fuel drainage, minimizing the risk of spills and ensuring that the process is both safe and efficient 2.

Key Features

The Fuel Drain Tube 3899526 is constructed from durable materials, ensuring it can withstand the rigors of commercial truck operation. Its design includes features such as a secure fitting to prevent leaks during operation and a robust valve mechanism for controlled fuel release. These attributes contribute to the tube’s performance and longevity, making it a reliable component in the fuel system 3.

Benefits

Utilizing the Fuel Drain Tube 3899526 offers several advantages. It enhances safety during fuel system maintenance by providing a controlled means of draining fuel, reducing the risk of spills and accidents. The ease of use is another benefit, as the tube is designed for straightforward operation, allowing for quick and efficient fuel drainage. Additionally, its reliability in various operating conditions ensures consistent performance, contributing to the overall efficiency of the fuel system 4.

Installation and Usage

Proper installation of the Fuel Drain Tube 3899526 is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines, ensuring a secure fit within the fuel system. Usage involves activating the valve mechanism to initiate fuel drainage, a process that should be conducted in a well-ventilated area to ensure safety 5.

Maintenance and Care

Regular maintenance of the Fuel Drain Tube 3899526 is recommended to ensure its longevity and consistent performance. This includes periodic inspection for signs of wear or damage and cleaning the tube to remove any debris that may accumulate. Adhering to these maintenance practices will help prevent issues and ensure the tube remains functional 6.

Troubleshooting Common Issues

Common issues with the Fuel Drain Tube 3899526 may include leaks or difficulty in activating the valve mechanism. Troubleshooting steps should begin with a thorough inspection of the tube and its connections for any visible damage or loose fittings. Ensuring the valve mechanism is free from obstructions and operates smoothly can also address many common problems 7.

Safety Considerations

When working with the Fuel Drain Tube 3899526, it is important to observe safety precautions. This includes working in a well-ventilated area to avoid the accumulation of fuel vapors and wearing appropriate personal protective equipment. Additionally, compliance with industry standards for fuel system maintenance and operation is crucial to ensure safety and environmental protection 8.

Cummins Overview

Cummins Inc. is a leader in the diesel engine manufacturing industry, with a history of innovation and commitment to quality. The company’s expertise in engine technology and components, including the Fuel Drain Tube 3899526, underscores its dedication to providing reliable and high-performance solutions for the automotive industry 9.

Compatibility

The Cummins Fuel Drain Tube, part number 3899526, is designed to fit seamlessly within various engine configurations. This component is integral to the fuel system, ensuring that any water or contaminants are effectively drained from the fuel tank.

L10 MECHANICAL Engines

The L10 MECHANICAL engine series is one of the prominent platforms where the Cummins Fuel Drain Tube (3899526) is utilized. This engine is known for its robust design and reliability, often used in heavy-duty applications. The fuel drain tube in this engine is strategically positioned to facilitate the removal of water and other impurities from the fuel tank, thereby maintaining the engine’s performance and longevity.

The installation of the fuel drain tube in the L10 MECHANICAL engine is straightforward, ensuring that it integrates smoothly with the existing fuel system components. This design allows for easy maintenance and replacement, making it a preferred choice for technicians and operators alike.

Group Compatibility

The Cummins Fuel Drain Tube (3899526) is not limited to the L10 MECHANICAL engine series. It is also compatible with various other engine groups within the Cummins portfolio. This compatibility extends to engines that share similar fuel system architectures, ensuring that the part can be used across multiple platforms without requiring significant modifications.

By maintaining a consistent design across different engine groups, Cummins ensures that the fuel drain tube can be easily sourced and installed, reducing downtime and maintenance costs. This approach underscores Cummins’ commitment to providing reliable and versatile components for their engines.

Role in Fuel Plumbing Systems

In fuel plumbing systems, the 3899526 Fuel Drain Tube is an integral component that facilitates the safe and efficient drainage of fuel. This part is designed to work in conjunction with various elements within the fuel system to ensure optimal performance and safety.

Integration with Fuel Lines

The Fuel Drain Tube is typically connected to the fuel lines, allowing for the controlled release of fuel when necessary. This connection is essential for maintenance procedures, such as fuel system purging or when switching between different types of fuel. The tube ensures that fuel can be drained without causing spills or contamination, maintaining the integrity of the fuel system.

Connection to Fuel Tanks

In systems where direct access to the fuel tank is required, the Fuel Drain Tube is often routed to a drain point at the bottom of the tank. This setup allows for comprehensive draining of the tank, which is particularly useful during maintenance or when the fuel needs to be changed. The tube’s design ensures a secure connection, preventing leaks and ensuring that the drainage process is smooth and controlled.

Interaction with Fuel Filters

The Fuel Drain Tube also plays a role in the maintenance of fuel filters. By providing a means to drain fuel from the filter housing, it allows mechanics to replace or clean filters without the risk of fuel spillage. This is particularly important in high-pressure fuel systems, where residual fuel in the lines and filters can pose a safety hazard.

Use in Fuel Injectors and Carburetors

For engines equipped with fuel injectors or carburetors, the Fuel Drain Tube is used to drain fuel from these components. This is vital during servicing or when the engine is not in use for extended periods, as it prevents fuel degradation and potential damage to the injectors or carburetor. The tube ensures that fuel can be safely removed, reducing the risk of clogs or malfunctions.

Application in Fuel Pumps

In systems with fuel pumps, the Fuel Drain Tube is used to drain fuel from the pump housing and fuel lines. This is important for maintaining the pump’s efficiency and longevity. Regular drainage helps prevent the buildup of contaminants and ensures that the pump operates within optimal parameters.

Role in Emergency Situations

In emergency situations, such as fuel leaks or system malfunctions, the Fuel Drain Tube provides a quick and safe way to evacuate fuel from the system. This can be a lifesaving feature, allowing for rapid response to potential hazards and minimizing the risk of fire or explosion.

Conclusion

Overall, the 3899526 Fuel Drain Tube is a versatile component that enhances the safety and efficiency of fuel plumbing systems across various engine types. Its role in facilitating controlled fuel drainage is indispensable for both routine maintenance and emergency situations.

-

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Reif, K. (2015). Automotive Mechatronics. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 3666184-00: Troubleshooting and Repair Manual.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 3666184-00: Troubleshooting and Repair Manual.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 3666184-00: Troubleshooting and Repair Manual.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 3666184-00: Troubleshooting and Repair Manual.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 3666184-00: Troubleshooting and Repair Manual.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 3666184-00: Troubleshooting and Repair Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.