This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3818615 Fuel Drain Pipe is a component designed for use in the fuel systems of commercial trucks. Its primary role is to facilitate the draining of fuel from the system, which is necessary for routine maintenance or in emergency situations. This part is integral to ensuring the fuel system operates efficiently and safely, contributing to the overall performance and reliability of the vehicle 1.

Purpose and Function

The Cummins 3818615 Fuel Drain Pipe serves a specific function within the truck’s fuel system. It allows for the controlled release of fuel, which is important for maintenance tasks such as filter changes or system cleaning. Additionally, in emergency scenarios where fuel contamination is suspected, the drain pipe enables the quick removal of fuel to prevent engine damage. This component ensures that the fuel system can be safely and effectively managed, maintaining the truck’s operational integrity 2.

Key Features

The design and construction of the Cummins 3818615 Fuel Drain Pipe are tailored to meet the demanding requirements of commercial truck applications. It is made from durable materials that resist corrosion and wear, ensuring longevity in harsh operating environments. The pipe features secure connection types that prevent leaks and maintain system integrity. Unique design elements, such as reinforced sections and precise engineering, enhance its performance and durability, making it a reliable component in the fuel system 3.

Benefits

Utilizing the Cummins 3818615 Fuel Drain Pipe offers several advantages. It simplifies fuel system maintenance by providing a straightforward method for draining fuel, which can reduce downtime during service intervals. The pipe’s design enhances safety during fuel draining procedures by ensuring a controlled and leak-free process. Additionally, its compatibility with Cummins engines ensures seamless integration and optimal performance within the specified systems.

Installation and Usage

Proper installation of the Cummins 3818615 Fuel Drain Pipe is crucial for its effective operation. Installation guidelines should be followed to ensure secure connections and proper alignment within the fuel system. Users should refer to specific instructions provided by the manufacturer to avoid common installation pitfalls. During usage, it is important to operate the drain pipe according to recommended procedures to maintain system efficiency and safety.

Maintenance and Troubleshooting

To ensure the longevity and reliable operation of the Cummins 3818615 Fuel Drain Pipe, regular maintenance is recommended. This includes inspecting the pipe for signs of wear or damage, ensuring connections remain tight, and cleaning the area around the pipe to prevent debris accumulation. Common issues such as leaks or blockages can often be addressed by following troubleshooting steps outlined in the manufacturer’s guidelines, which may include checking for proper installation, verifying connection integrity, and cleaning or replacing damaged components as necessary.

Safety Considerations

When working with the Cummins 3818615 Fuel Drain Pipe, it is important to adhere to safety practices to protect both the operator and the equipment. This includes handling fuel with care to avoid spills and contamination, using appropriate personal protective equipment (PPE) such as gloves and safety glasses, and following manufacturer guidelines for operation and maintenance. Additionally, ensuring that the work area is well-ventilated and free from ignition sources is crucial when dealing with fuel systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines. The company’s product offerings include a wide range of diesel and natural gas engines, as well as related components and technologies, all designed to meet the rigorous demands of commercial transportation.

Compatibility

This Cummins part is designed to fit seamlessly within a variety of engine configurations, ensuring efficient fuel management and system integrity. It is engineered to meet the specific needs of the following engines:

- L10 MECHANICAL

When installed in the L10 MECHANICAL engine, the fuel drain pipe plays a role in the fuel system by facilitating the removal of excess fuel and contaminants. This helps maintain optimal engine performance and longevity by preventing the accumulation of unwanted substances within the fuel lines and components.

The design of the fuel drain pipe ensures a secure fit and reliable operation across different engine models, making it a versatile component for various applications. Its compatibility with the L10 MECHANICAL engine underscores its importance in maintaining the efficiency and reliability of the engine’s fuel system.

Role in Fuel Plumbing Systems

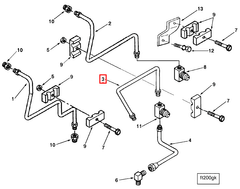

This part is an integral component within the fuel plumbing system of an engine. Its primary function is to facilitate the safe and efficient removal of fuel from the system, ensuring that any excess or contaminated fuel is directed away from the engine and into a designated collection area.

In the context of fuel plumbing, the Fuel Drain Pipe interfaces with several key components:

-

Fuel Tank: The pipe is typically connected to the fuel tank, allowing for the drainage of fuel when necessary. This is particularly important during maintenance procedures or when the fuel quality is in question.

-

Fuel Lines: The pipe is integrated into the fuel lines network, providing a dedicated pathway for fuel to be drained without disrupting the normal flow of fuel to the engine.

-

Fuel Filters: In systems where fuel filters are present, the Fuel Drain Pipe may be connected downstream of the filter. This allows for the removal of fuel that may have bypassed the filter or become contaminated after filtration.

-

Fuel Injectors: In some configurations, the pipe may be connected near the fuel injectors to allow for the drainage of fuel that has not been atomized properly or has become contaminated.

-

Fuel Return System: If the engine features a fuel return system, the Fuel Drain Pipe may be part of this network, allowing for the drainage of fuel that has been returned from the injectors back to the tank.

The effective integration of the Fuel Drain Pipe within these components ensures that the fuel system remains clean and operates efficiently. It allows for routine maintenance and troubleshooting by providing a straightforward method for fuel removal, which is essential for the longevity and performance of the engine.

Conclusion

The Cummins 3818615 Fuel Drain Pipe is a critical component in the maintenance and operation of commercial truck fuel systems. Its design and functionality contribute to the efficiency, safety, and reliability of the fuel system, ensuring that engines operate at optimal performance levels. Regular maintenance and adherence to safety practices are essential to maximize the benefits of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.