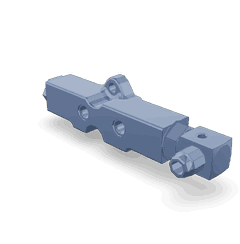

3629408

Fuel Block Connection

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Fuel Block Connection, part number 3629408, is a critical component in the fuel delivery system of commercial trucks. Manufactured by Cummins, a reputable name in the commercial truck industry, this part plays a significant role in ensuring efficient fuel transfer from the tank to the engine. Understanding its functionality and importance can provide valuable insights into maintaining and optimizing truck performance.

Basic Concepts of Fuel Block Connection

A Fuel Block Connection is a vital component within the fuel system of a truck, facilitating the transfer of fuel from the fuel tank to the engine. It acts as an interface, connecting various fuel lines and ensuring a consistent flow of fuel. This connection integrates with other components such as fuel filters, pumps, and injectors, playing a pivotal role in the overall fuel delivery process 1.

Purpose of the Cummins Fuel Block Connection

The Cummins Fuel Block Connection (part 3629408) is designed to enhance the operation of a truck’s fuel delivery system. It ensures that fuel is efficiently transferred from the tank to the engine, contributing to stable engine performance. By maintaining a consistent fuel flow, it supports the engine’s combustion process, which is vital for power output and overall efficiency 2.

Key Features

This Cummins part boasts several key features that enhance its functionality. It is constructed from durable materials to withstand the pressures and temperatures within the fuel system. Its design includes precise fittings and connections to ensure a secure and leak-free interface with other components. Additionally, it may incorporate features such as built-in filters to prevent contaminants from entering the fuel system 3.

Benefits

Incorporating the Cummins Fuel Block Connection into a truck’s fuel system can lead to several benefits. It contributes to improved fuel efficiency by ensuring a consistent and clean fuel supply to the engine. This can result in enhanced reliability and potentially lower operating costs for fleet operators. Moreover, its robust construction and design elements support longevity and reduced maintenance requirements 4.

Installation Process

Installing the Cummins Fuel Block Connection requires careful attention to detail. Before installation, ensure that the fuel system is clean and free of debris. Use the appropriate tools to connect the fuel block to the fuel lines and other components. Follow the manufacturer’s guidelines for torque specifications to secure connections without over-tightening. After installation, perform a system check to verify proper fuel flow and look for any signs of leaks.

Maintenance and Troubleshooting

Regular maintenance of the Cummins Fuel Block Connection is crucial for ensuring its longevity and optimal performance. Inspect the connections periodically for signs of wear or leaks. Clean the fuel block and surrounding components to prevent buildup of contaminants. If issues arise, such as fuel leaks or inconsistent fuel flow, troubleshoot by checking connections, inspecting for damage, and ensuring that all components are properly seated.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer in the commercial truck industry, known for its high-quality engines and components. With a history of innovation and reliability, Cummins offers a wide range of products designed to enhance the performance and efficiency of commercial trucks. Their commitment to quality and customer satisfaction has established them as a trusted name among fleet operators and maintenance professionals.

Cummins Fuel Block Connection (Part 3629408)

The Cummins Fuel Block Connection, identified by the part number 3629408, is a critical component in the fuel system architecture of several Cummins engines. This part is designed to ensure a secure and leak-free connection between the fuel block and the fuel lines, facilitating the efficient transfer of fuel within the engine’s system.

Application in Cummins Engines

K38 and K50 Engines

The Cummins Fuel Block Connection is integral to the K38 and K50 engine series. These engines are known for their robust performance and reliability, often utilized in heavy-duty applications such as construction equipment, agricultural machinery, and industrial power systems. The part 3629408 is engineered to meet the stringent demands of these engines, providing durability and consistent performance under varying operational conditions.

Compatibility and Installation

When installing the Fuel Block Connection in the K38 and K50 engines, it is essential to ensure that the part is correctly aligned and securely fastened. This connection is typically made during engine assembly or when performing maintenance on the fuel system. Proper installation is crucial to prevent fuel leaks, which can lead to engine performance issues and potential safety hazards.

Maintenance and Replacement

Regular maintenance checks should include inspecting the Fuel Block Connection for signs of wear, corrosion, or damage. If any issues are detected, the part should be replaced promptly to maintain the integrity of the fuel system. Cummins provides detailed guidelines and specifications for the maintenance and replacement of this component, ensuring that technicians can perform these tasks with confidence and precision.

Performance Impact

The quality and reliability of the Fuel Block Connection directly impact the overall performance and efficiency of the K38 and K50 engines. A well-maintained connection ensures optimal fuel flow, contributing to the engine’s power output and longevity. Conversely, a faulty connection can lead to reduced performance, increased fuel consumption, and potential engine damage.

Role of Part 3629408 Fuel Block Connection in Engine Systems

The Cummins Fuel Block Connection (part 3629408) is integral to the efficient operation of various engine systems. It serves as a pivotal interface that facilitates the seamless integration of several components, ensuring optimal fuel delivery and system performance.

Integration with Fuel Pump Conversion Kit

When installing a fuel pump conversion kit, the Cummins Fuel Block Connection acts as a bridge between the new fuel pump and the existing fuel lines. This ensures that the converted system maintains consistent fuel pressure and flow, which is essential for the engine’s performance. The connection point allows for easy adaptation of the new pump without requiring extensive modifications to the fuel lines.

Location and Drain Systems

In systems where precise location and efficient draining are necessary, the Cummins Fuel Block Connection provides a reliable point for both. It allows engineers and mechanics to accurately position fuel lines and components, ensuring that there are no leaks or inefficiencies. Additionally, it simplifies the drain process by offering a secure connection point that can be easily accessed for maintenance or emergency draining.

Plumbing and Fuel Supply

The connection plays a significant role in the overall plumbing of the fuel system. It ensures that the fuel supply lines are correctly aligned and sealed, preventing any fuel leaks that could pose a safety hazard. The secure fitting also maintains the integrity of the fuel supply, ensuring that the engine receives a consistent and clean fuel flow.

Valve and Check Systems

In conjunction with valves and check systems, the Cummins Fuel Block Connection enhances the regulation of fuel flow. It allows for the precise control of fuel delivery, ensuring that the engine operates within its optimal parameters. The connection point is designed to work seamlessly with check valves, preventing backflow and ensuring that fuel moves in the correct direction through the system.

Conclusion

The Cummins Fuel Block Connection (part 3629408) is a versatile and critical component that enhances the functionality and reliability of various engine systems. Its role in facilitating smooth transitions, secure connections, and efficient fuel management makes it an invaluable part of modern engine designs. Understanding its importance and proper maintenance can significantly contribute to the overall performance and efficiency of commercial trucks.

-

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Jazar, R. N. (2017). Vehicle Dynamics: Theory and Application. Springer.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.