This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

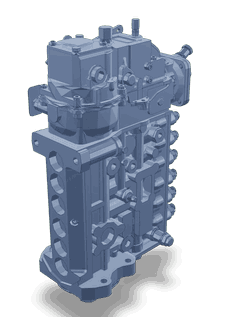

The Cummins 5313188 Fuel Injector Pump is a component designed for use in commercial truck engines. Manufactured by Cummins Inc., a well-established name in the diesel engine industry, this part is integral to the efficient operation of diesel engines in heavy-duty applications. Its role in ensuring optimal engine performance and fuel efficiency makes it a significant part of the engine system.

Basic Concepts of Fuel Injector Pumps

A fuel injector pump is a device that delivers fuel to the combustion chamber of a diesel engine. It operates by pressurizing fuel and injecting it into the engine’s cylinders at precise moments to facilitate combustion. The efficiency of this process is crucial for the engine’s performance, fuel economy, and emissions output 1.

Role of the Cummins 5313188 Fuel Injector Pump in Truck Operation

The Cummins 5313188 Fuel Injector Pump plays a specific role in the operation of commercial trucks by ensuring that fuel is delivered to the engine’s cylinders under the correct pressure and at the right time. This precise fuel delivery contributes to the engine’s performance, including its power output and fuel efficiency. The pump’s operation is synchronized with the engine’s management system to optimize these factors 2.

Key Features of the Cummins 5313188 Fuel Injector Pump

The Cummins 5313188 Fuel Injector Pump is characterized by its robust design, which includes high-quality materials that ensure durability and reliability. Technological advancements incorporated into this pump enhance its performance, making it suitable for the demanding conditions of commercial truck engines. These features contribute to its efficiency and longevity 3.

Benefits of Using the Cummins 5313188 Fuel Injector Pump

Utilizing the Cummins 5313188 Fuel Injector Pump offers several advantages. It provides improved fuel delivery, which leads to enhanced engine performance. The pump’s design and construction contribute to its reliability, ensuring consistent operation under various conditions. Additionally, its efficiency plays a role in reducing fuel consumption and emissions, aligning with environmental considerations.

Troubleshooting Common Issues with Fuel Injector Pumps

Common issues with fuel injector pumps, including the Cummins 5313188 model, can arise from wear and tear, contamination, or improper installation. Identifying these problems early through regular inspections and maintenance checks can prevent more significant issues. Addressing these concerns promptly ensures the continued efficient operation of the engine.

Maintenance Tips for Fuel Injector Pumps

To ensure the optimal performance and longevity of the Cummins 5313188 Fuel Injector Pump, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, cleaning or replacing filters to prevent contamination, and ensuring all connections are secure. Adhering to the manufacturer’s servicing guidelines can help maintain the pump’s efficiency and reliability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to innovation, quality, and customer satisfaction.

Advancements in Fuel Injector Pump Technology

Recent technological advancements in fuel injector pump design have led to improvements in engine efficiency and emissions. These innovations include more precise fuel delivery systems, integration with electronic engine management systems, and the use of materials that enhance durability and performance under high-stress conditions.

Environmental Impact and Fuel Efficiency

Advancements in fuel injector pump technology contribute to improved fuel efficiency and reduced environmental impact in commercial trucks. By ensuring more precise fuel delivery and combustion, these pumps help lower fuel consumption and emissions, aligning with global efforts to reduce the carbon footprint of transportation.

Integration with Engine Management Systems

Modern fuel injector pumps, including the Cummins 5313188, integrate with engine management systems to optimize performance. This integration allows for real-time adjustments to fuel delivery based on engine load, speed, and other operating conditions, enhancing efficiency and responsiveness.

Common Misconceptions about Fuel Injector Pumps

There are several misconceptions about fuel injector pumps, including their complexity and the necessity for frequent replacements. In reality, with proper maintenance and care, these pumps can offer reliable service for extended periods. Understanding their operation and the importance of maintenance can dispel these myths.

Future Trends in Fuel Injector Pump Technology

Looking ahead, future developments in fuel injector pump technology are likely to focus on further enhancing efficiency, reducing emissions, and integrating with advanced engine management systems. Innovations may include the use of alternative fuels, smarter diagnostics, and more compact designs that fit within the evolving landscape of commercial truck engines.

Cummins Fuel Injector Pump 5313188 Compatibility

The Cummins Fuel Injector Pump part number 5313188 is designed to fit seamlessly with a variety of engine models, ensuring optimal performance and reliability. This part is engineered to meet the specific needs of the engines it is compatible with, providing precise fuel delivery and enhancing overall engine efficiency.

Compatible Engines

-

6B5.9 Series

- The 5313188 fuel injector pump is specifically tailored for the 6B5.9 engines. This compatibility ensures that the pump can handle the unique demands of these engines, providing the necessary fuel pressure and timing for efficient operation.

-

Other Cummins Engines

- While the 5313188 is prominently used in the 6B5.9 series, it is also compatible with other Cummins engines within the same family. This broad compatibility allows for easier maintenance and repair, as technicians can use a single part number for multiple engine types, reducing inventory needs and simplifying the repair process.

Installation and Integration

The installation of the Cummins Fuel Injector Pump 5313188 is straightforward, designed to integrate smoothly with the engine’s existing fuel system. Proper installation ensures that the pump can deliver fuel at the correct pressure and timing, which is crucial for maintaining engine performance and longevity.

-

Precision Engineering

- The pump is engineered with precision to ensure it fits perfectly within the engine’s fuel system. This precision engineering minimizes the risk of leaks and ensures that the pump operates efficiently from the moment of installation.

-

Quality Assurance

- Cummins is known for its stringent quality control processes, and the 5313188 fuel injector pump is no exception. Each pump undergoes rigorous testing to ensure it meets the highest standards of performance and reliability.

By choosing the Cummins Fuel Injector Pump 5313188, technicians and engine owners can be confident that they are using a part that is designed to work seamlessly with their engines, providing the necessary fuel delivery for optimal performance.

Role of Part 5313188 Fuel Injector Pump in Engine Systems

The part 5313188 Fuel Injector Pump is integral to the efficient operation of engine systems, particularly in diesel engines. This component works in conjunction with several other parts to ensure optimal fuel delivery and combustion.

Interaction with the Fuel System

-

Fuel Tank: The process begins with the fuel stored in the fuel tank. The fuel injector pump draws diesel from the tank through the fuel lines.

-

Fuel Filter: Before reaching the fuel injector pump, the diesel passes through the fuel filter. This step ensures that any impurities are removed, protecting the injector pump from damage and ensuring clean fuel delivery.

-

Fuel Lines: The clean, filtered fuel is then transported via fuel lines to the fuel injector pump. These lines must be robust and leak-free to maintain consistent fuel pressure and flow.

Function within the Engine

-

Fuel Injector Pump: Once the fuel reaches the injector pump, it is pressurized. The pump precisely meters the fuel and delivers it to the injectors at the correct pressure and timing.

-

Fuel Injectors: The pressurized fuel is then sprayed into the combustion chambers through the fuel injectors. The injectors atomize the fuel, creating a fine mist that mixes with the air for efficient combustion.

-

Combustion Chamber: Inside the combustion chamber, the atomized fuel mixes with compressed air. The fuel injector pump’s precise timing ensures that the fuel is delivered at the optimal moment for combustion, maximizing engine efficiency and power output.

-

Engine Performance: The efficient combustion driven by the fuel injector pump results in smooth engine operation, reduced emissions, and improved fuel economy.

Maintenance and Efficiency

Regular maintenance of the fuel injector pump and associated components is essential for sustained engine performance. This includes checking fuel lines for leaks, ensuring the fuel filter is clean, and verifying that the injector pump is delivering fuel at the correct pressure.

By understanding the interplay between the fuel injector pump and other engine components, engineers and mechanics can better diagnose issues, perform maintenance, and optimize engine performance.

Conclusion

The Cummins 5313188 Fuel Injector Pump is a critical component in the operation of commercial truck engines, ensuring efficient fuel delivery and combustion. Its robust design, compatibility with various engine models, and integration with engine management systems contribute to enhanced engine performance, fuel efficiency, and reduced emissions. Regular maintenance and understanding of its role within the engine system are essential for optimal operation and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.