This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

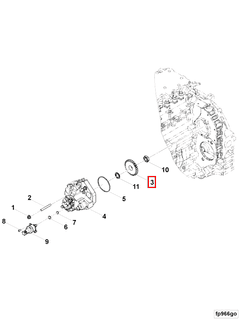

The Cummins 5273414 Fuel Pump Gear is a critical component in the fuel systems of commercial trucks, manufactured by Cummins Inc., a prominent figure in the diesel engine industry. This part ensures precise fuel delivery, which is essential for engine performance and efficiency.

Basic Concepts of Fuel Pump Gears

Fuel pump gears are vital components within diesel engine fuel injection systems. They transfer mechanical energy from the engine’s camshaft to the fuel pump, enabling it to pressurize and deliver fuel to the injectors. The efficiency of this transfer directly influences fuel delivery and combustion 1.

Role of the 5273414 Fuel Pump Gear in Truck Operation

This Cummins part ensures the smooth and consistent transfer of mechanical energy from the camshaft to the fuel pump. This transfer is essential for maintaining the required fuel pressure and timing, crucial for optimal engine performance. The gear interacts with other fuel system components, such as the fuel pump and injectors, to facilitate efficient fuel delivery 2.

Key Features of the 5273414 Fuel Pump Gear

The 5273414 is designed for performance, durability, and efficiency. It is made from high-quality materials resistant to wear and corrosion. Precision engineering ensures accurate meshing with other components, minimizing friction and maximizing efficiency. Unique design elements may include specialized tooth profiles for optimal power transmission and reduced noise.

Benefits of Using the 5273414 Fuel Pump Gear

Utilizing this part can lead to improved fuel efficiency, enhanced engine performance, and increased reliability. Its precise design and high-quality materials contribute to more efficient fuel delivery, resulting in better overall engine performance. For commercial truck operations, this means potentially lower operating costs and increased uptime due to the gear’s reliability and durability 3.

Troubleshooting Common Issues with Fuel Pump Gears

Identifying and addressing common problems associated with fuel pump gears is crucial for maintaining engine performance. Symptoms of failure may include irregular engine operation, decreased fuel efficiency, or difficulty starting the engine. Diagnostic procedures should involve inspecting the gear for signs of wear or damage and ensuring proper alignment and engagement with other components. Preventive maintenance practices, such as regular inspections and timely replacements, can help avoid these issues.

Maintenance Tips for the 5273414 Fuel Pump Gear

Regular maintenance practices are essential for ensuring the longevity and optimal performance of the 5273414. This includes periodic inspection for wear or damage, cleaning to remove any contaminants that could affect performance, and following manufacturer guidelines for replacement intervals. Adhering to these practices can help maintain the gear’s efficiency and reliability.

Compatibility and Performance

The 5273414 is compatible with several Cummins engine models, including the ISB (Chrysler), ISB CM850, and QSB5.9 CM850. It is engineered to integrate smoothly with these engines, providing the necessary mechanical advantage to drive the fuel pump. This ensures that the fuel is delivered at the correct pressure and flow rate, which is critical for maintaining engine efficiency and performance.

Installation and Maintenance

Installing the 5273414 is a straightforward process, thanks to its precise engineering. It is designed to fit seamlessly with the existing components of the fuel system, ensuring a hassle-free installation. Regular maintenance of this part is crucial to ensure continued engine performance and reliability. Cummins recommends periodic inspection and replacement of the gear as part of routine engine maintenance.

Conclusion

The Cummins 5273414 Fuel Pump Gear is a vital component in the fuel systems of commercial trucks, ensuring precise fuel delivery and contributing to engine performance and efficiency. Its design, compatibility with various Cummins engine models, and the importance of regular maintenance underscore its role in the efficient operation of diesel engines.

-

Andrew Brown Jr, Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, National Academy of Sciences, 2010.

↩ -

Addy Majewski and Hannu Jaskelainen, Diesel Emissions and Their Control: Second Edition, SAE International, 2023.

↩ -

Ben Watson, Mobile Equipment Hydraulics A Systems and Troubleshooting Approach, Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.