The Fuel Supply Tube, identified by Part #5270193, is a component manufactured by Cummins, a leader in the commercial truck industry. This part is integral to the fuel system of heavy-duty trucks, facilitating the efficient delivery of fuel from the tank to the engine. Understanding its role and functionality is key to maintaining the performance and reliability of the vehicle.

Basic Concepts of Fuel Supply Tubes

A Fuel Supply Tube is a conduit within the fuel system designed to transport fuel from the tank to the engine. It operates under pressure, ensuring a consistent and reliable fuel supply that is critical for engine performance. The tube is engineered to withstand the pressures and temperatures associated with fuel transport, ensuring that fuel is delivered efficiently and without interruption 1.

Purpose of the 5270193 Fuel Supply Tube

This Cummins part plays a significant role in the operation of a truck by facilitating the delivery of fuel from the tank to the engine. This ensures that the engine receives a steady supply of fuel, which is necessary for combustion and, consequently, for the truck’s movement. The tube’s design and material are tailored to handle the specific pressures and temperatures within the fuel system, contributing to the overall efficiency and reliability of the truck 2.

Key Features

This part is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and wear, ensuring longevity. The design includes precise fittings and connections that prevent leaks and ensure a secure fit within the fuel system. Additionally, the tube is engineered to withstand the high pressures and temperatures associated with fuel delivery, contributing to its reliability 3.

Benefits

The advantages provided by this part include improved fuel efficiency, reliability, and longevity. Its high-quality construction and precise engineering contribute to a consistent and efficient fuel delivery system, which can enhance the overall performance of the truck. Additionally, the tube’s durability and resistance to wear and corrosion contribute to its longevity, reducing the need for frequent replacements 4.

Installation Process

The proper installation of this part involves several steps to ensure optimal performance. It begins with the preparation of the fuel system, ensuring that all connections are clean and free from debris. The tube is then fitted into place, with careful attention paid to ensuring that all connections are secure and leak-free. Finally, the system is tested to ensure that fuel is delivered efficiently and without interruption.

Common Issues and Troubleshooting

Typical problems associated with Fuel Supply Tubes include leaks and blockages. Leaks can occur due to worn or damaged fittings, while blockages may result from debris within the fuel system. Troubleshooting these issues involves inspecting the tube and its connections for signs of wear or damage, and cleaning the fuel system to remove any debris that may be causing blockages.

Maintenance Tips

Regular maintenance practices can prolong the lifespan of this part. This includes inspecting the tube and its connections for signs of wear or damage, and cleaning the fuel system to remove any debris that may be causing blockages. Additionally, following the manufacturer’s recommended inspection schedules can help identify potential issues before they become serious problems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Cummins Fuel Supply Tube Part 5270193 Compatibility

This part is designed to integrate seamlessly with a variety of Cummins engines, ensuring efficient fuel delivery and optimal engine performance. This part is specifically engineered to fit within the engine systems of the following Cummins engines:

- QSB4.5 CM2250 EC

This part is crucial for maintaining the integrity of the fuel system, ensuring that fuel is delivered accurately and consistently to the engine components. Its compatibility with the QSB4.5 CM2250 EC engine underscores its importance in the engine’s overall functionality and performance.

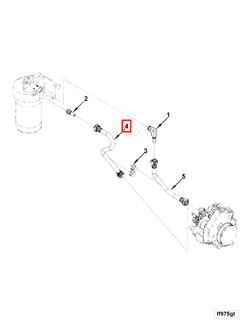

Role of Part 5270193 Fuel Supply Tube in Engine Systems

The Fuel Supply Tube (Part 5270193) is integral to the efficient operation of engine systems, ensuring a steady and reliable flow of fuel from the fuel tank to the engine’s fuel injection system. This component interfaces directly with the Fuel Filter Plumbing, creating a seamless connection that minimizes fuel leakage and maintains consistent fuel pressure.

In the context of engine systems, the Fuel Supply Tube works in conjunction with the fuel filter to deliver clean, pressurized fuel to the injectors. The tube’s design allows it to withstand the high pressures and temperatures within the fuel system, ensuring durability and performance.

Additionally, the Fuel Supply Tube is engineered to reduce fuel line restrictions, which enhances fuel delivery efficiency. This is particularly important in high-performance engines where precise fuel metering is essential for optimal combustion and power output.

The integration of the Fuel Supply Tube with the fuel filter plumbing also facilitates easier maintenance and replacement, reducing downtime and enhancing the overall reliability of the engine system.

Conclusion

Understanding the role and functionality of the 5270193 Fuel Supply Tube is essential for maintaining the performance and reliability of heavy-duty trucks. Its high-quality construction, precise engineering, and compatibility with various Cummins engines make it a critical component in the fuel delivery system. Regular maintenance and proper installation are key to ensuring the longevity and efficiency of this part.

-

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.