This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

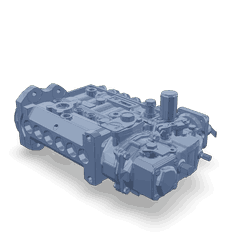

The Cummins 5256100 Fuel Injection Pump is a component designed for use in commercial trucks, playing a significant role in the efficient operation of diesel engines. This part is integral to the fuel delivery system, ensuring that fuel is supplied to the engine cylinders at the correct timing and pressure, which is vital for optimal engine performance and efficiency 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers pressurized fuel into the combustion chamber of a diesel engine. It operates by drawing fuel from the tank, pressurizing it, and injecting it into the engine cylinders at precise moments in the engine cycle. This process is crucial for efficient combustion and power generation 2. Fuel injection systems can be mechanical or electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, whereas electronic systems use sensors and computer controls to manage fuel injection more precisely, offering benefits such as improved fuel efficiency and reduced emissions 3.

Purpose and Function of the Cummins 5256100 Fuel Injection Pump

This Cummins part is designed to deliver fuel to the engine cylinders of commercial trucks at precise timing and pressure. This ensures efficient combustion, which is fundamental for the engine’s performance and fuel efficiency. The pump’s role in maintaining the correct fuel delivery parameters is crucial for the overall operation and reliability of the truck’s engine 4.

Key Features

The Cummins 5256100 Fuel Injection Pump features a robust design that includes precision-machined components to ensure accurate fuel delivery. Its construction incorporates high-quality materials to withstand the high pressures and temperatures within the fuel system. Unique characteristics of this pump may include advanced sealing technologies and durable housing materials, which contribute to its reliability and longevity in demanding commercial truck applications.

Benefits of Using the Cummins 5256100 Fuel Injection Pump

Utilizing this Cummins part offers several advantages. These include improved fuel efficiency due to precise fuel delivery, enhanced engine performance through optimal combustion, and increased reliability thanks to its robust construction and advanced features. These benefits contribute to the overall efficiency and longevity of the truck’s engine.

Installation and Integration

Proper installation and integration of the Cummins 5256100 Fuel Injection Pump into a truck’s engine system are vital for ensuring optimal performance and reliability. It is important to follow manufacturer specifications during installation to avoid issues such as fuel leaks or improper fuel delivery, which could affect engine performance. Careful attention to alignment, secure mounting, and correct connection of all fuel lines and electrical components is necessary.

Maintenance and Troubleshooting

Routine maintenance practices are recommended to ensure the longevity and efficiency of the Cummins 5256100 Fuel Injection Pump. This includes regular inspection of fuel lines and connections for leaks, cleaning or replacing filters as needed, and checking for proper operation of all components. Common issues may include fuel delivery problems or pump wear, which can often be diagnosed through systematic troubleshooting procedures that involve checking fuel pressure, inspecting electrical connections, and verifying the operation of mechanical components.

Performance Optimization

Strategies for optimizing the performance of the Cummins 5256100 Fuel Injection Pump include ensuring the use of high-quality fuel and filters to prevent contamination and wear. Additionally, keeping the pump and its components clean and well-maintained can help maintain optimal performance. In some cases, tuning or upgrades may be available to further enhance the pump’s efficiency and output, though these should be approached with caution and ideally performed by qualified professionals.

Safety Considerations

When working with the Cummins 5256100 Fuel Injection Pump, it is important to observe safety practices and precautions. This includes understanding the risks associated with high-pressure fuel systems and electrical components. Proper handling, use of personal protective equipment, and adherence to safety guidelines when performing maintenance or repairs are crucial to prevent accidents and ensure a safe working environment.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and fuel systems. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to advancing technology and meeting the needs of its customers is evident in its diverse product range and continuous investment in research and development.

Cummins Fuel Injection Pump 5256100 Compatibility

The Cummins Fuel Injection Pump part number 5256100 is designed to fit seamlessly with a variety of Cummins engines, ensuring optimal performance and reliability. This part is engineered to meet the stringent requirements of the engines it supports, providing precise fuel delivery and efficient combustion.

L8.9 Engine

The Cummins L8.9 engine is one of the models that benefit from the 5256100 Fuel Injection Pump. This engine is known for its robust construction and high power output, making it suitable for heavy-duty applications. The 5256100 pump is specifically calibrated to work with the L8.9 engine, ensuring that it delivers the necessary fuel at the right pressure and timing for peak performance.

Grouping of Compatible Engines

The 5256100 Fuel Injection Pump is not limited to the L8.9 engine alone. It is also compatible with other Cummins engines within the same family or those that share similar design characteristics. This compatibility is achieved through meticulous engineering and testing, ensuring that the pump can handle the demands of various engine configurations while maintaining its precision and durability.

By integrating the 5256100 Fuel Injection Pump into these engines, users can expect enhanced fuel efficiency, reduced emissions, and improved overall engine performance. The pump’s design allows for precise control over fuel delivery, which is crucial for maintaining the engine’s power and efficiency across different operating conditions.

Role of Part 5256100 Fuel Injection Pump in Engine Systems

The part 5256100 Fuel Injection Pump is integral to the efficient operation of engine systems, particularly in diesel engines. This component works in conjunction with several other parts to ensure optimal fuel delivery and combustion.

Interaction with the Fuel System

-

Fuel Tank: The process begins with the fuel stored in the fuel tank. The fuel injection pump draws diesel from the tank through the fuel lines.

-

Fuel Filter: Before reaching the injection pump, the fuel passes through the fuel filter. This filter removes impurities and ensures that only clean fuel enters the pump.

-

Fuel Injection Pump (Part 5256100): Once the clean fuel reaches the injection pump, it is pressurized. The pump precisely meters the fuel and delivers it to the injectors at the correct pressure and timing.

-

Fuel Injectors: The pressurized fuel is then sent to the fuel injectors. These injectors spray the fuel into the combustion chamber in a fine mist, ensuring thorough mixing with air for efficient combustion.

Engine Performance

-

Combustion Chamber: The atomized fuel mixes with the compressed air in the combustion chamber. The precise timing and pressure provided by the fuel injection pump ensure that the fuel burns efficiently, maximizing power output and minimizing emissions.

-

Crankshaft and Pistons: The combustion process generates force, which is transferred to the crankshaft via the pistons. The fuel injection pump’s role in ensuring consistent and efficient fuel delivery directly impacts the engine’s performance and smoothness of operation.

Maintenance and Efficiency

-

Regular Servicing: The fuel injection pump requires regular maintenance to ensure it operates within specified parameters. This includes checking for leaks, ensuring proper fuel pressure, and verifying the timing of fuel delivery.

-

System Integration: The pump must be correctly aligned with the engine’s camshaft or crankshaft, depending on the engine design. This synchronization ensures that fuel injection occurs at the optimal moment in the engine cycle.

Conclusion

In summary, the part 5256100 Fuel Injection Pump is a key component in the fuel delivery system, working seamlessly with other parts to enhance engine efficiency, performance, and reliability. Its precise control over fuel delivery is crucial for maintaining the engine’s power and efficiency across different operating conditions.

-

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Mananathan, R. Automobile Wheel Alignment and Wheel Balancing. SAE International, 2022.

↩ -

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Ferrari, Alessandro, and Pietro Pizzo. Injection Technologies: Mixture Formation Strategies. SAE International, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.