This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Fuel Shutoff Valve, part number 4985544, is a component designed to manage the flow of fuel within the fuel system of heavy-duty trucks. Its purpose is to ensure that fuel delivery is precisely controlled, which is significant for the efficient and safe operation of the vehicle. This part is integral to maintaining the performance and reliability of the truck’s engine.

Basic Concepts of Fuel Shutoff Valves

A Fuel Shutoff Valve is a device that regulates the flow of fuel to the engine. Its primary function is to open and close the fuel line, allowing or preventing fuel from reaching the engine. This control is vital for starting and stopping the engine, as well as for safety in emergency situations. The valve operates through mechanical or electronic signals, depending on the truck’s system design, to open or close in response to various conditions 1.

Purpose and Role of the Cummins Fuel Shutoff Valve

The Cummins Fuel Shutoff Valve is specifically designed to play a role in the operation of heavy-duty trucks by controlling the fuel supply to the engine. In routine operations, it ensures that fuel is delivered efficiently to the engine, contributing to optimal performance. In emergency situations, it can be activated to stop the fuel flow immediately, which is a safety feature that helps prevent engine damage or fire in the event of a crash or other critical incidents 2.

Key Features

The Cummins Fuel Shutoff Valve is characterized by several key features that enhance its performance and reliability. Its design incorporates durable materials that can withstand the high pressures and temperatures of the fuel system. The valve is engineered for precision operation, ensuring that it opens and closes smoothly and reliably. Additionally, it may include unique attributes such as corrosion-resistant coatings or advanced sealing mechanisms to maintain its functionality over time.

Benefits of Using the Cummins Fuel Shutoff Valve

Utilizing the Cummins Fuel Shutoff Valve offers several advantages. It contributes to improved safety by providing a reliable means to cut off fuel in emergencies. It also enhances engine protection by ensuring that fuel is delivered consistently and efficiently, which can lead to better engine performance and longevity. Furthermore, the valve’s precise control over fuel flow can increase operational efficiency, potentially leading to fuel savings and reduced emissions.

Installation and Integration

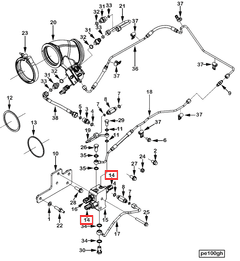

When installing the Cummins Fuel Shutoff Valve, it is important to follow guidelines to ensure optimal performance and compatibility with the truck’s fuel system. Proper integration involves securing the valve in the correct position within the fuel line, ensuring that all connections are tight and secure. It is also important to verify that the valve is compatible with the truck’s engine and fuel system specifications to avoid any issues with operation.

Troubleshooting Common Issues

Common problems associated with Fuel Shutoff Valves can include leaks, failure to open or close properly, or electrical issues in the case of electronically controlled valves. Symptoms may include difficulty starting the engine, irregular engine operation, or the engine not shutting off when expected. Potential causes can range from mechanical wear to electrical faults. Recommended troubleshooting steps include inspecting the valve for physical damage, checking electrical connections, and testing the valve’s operation to identify and resolve the issue 1.

Maintenance and Care

Regular maintenance and care of the Cummins Fuel Shutoff Valve are important to ensure its longevity and reliable operation. This includes periodic inspection for signs of wear or damage, cleaning the valve and its connections to remove any debris, and checking the operation of the valve to ensure it opens and closes as intended. Following manufacturer recommendations for inspection intervals and maintenance procedures can help prevent issues and extend the valve’s service life.

Safety Considerations

When working with the Cummins Fuel Shutoff Valve, it is important to observe safety protocols to ensure personal safety and the proper functioning of the valve. This includes wearing appropriate personal protective equipment, ensuring that the fuel system is depressurized before working on the valve, and following all manufacturer guidelines for handling and maintenance. Proper maintenance not only ensures the valve’s reliability but also contributes to the overall safety of the vehicle’s operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history of innovation and quality, Cummins has established itself as a trusted name in the automotive industry. The company’s commitment to excellence is reflected in its products, including the Cummins Fuel Shutoff Valve, which is designed to meet the demanding requirements of heavy-duty truck applications.

Cummins Fuel Shutoff Valve 4985544 Compatibility

The Cummins Fuel Shutoff Valve part number 4985544 is designed to ensure the safe and efficient operation of various Cummins engines. This valve is engineered to fit seamlessly with a range of Cummins engine models, providing reliable control over fuel flow. Below is a detailed overview of the engines with which this part is compatible:

ISB (Chrysler) Series

- ISB CM876: The 4985544 valve is compatible with the ISB CM876 engine, ensuring precise fuel shutoff capabilities.

- ISB11.9 CM871: This valve fits the ISB11.9 CM871 engine, providing essential control over fuel delivery.

ISX Series

- ISX CM871: The 4985544 valve is designed to integrate with the ISX CM871 engine, offering dependable fuel shutoff functionality.

- ISX12 CM2350 X102: This valve is compatible with the ISX12 CM2350 X102 engine, ensuring optimal performance and safety.

- ISX12/ISX11.9 CM2250: The 4985544 valve fits the ISX12/ISX11.9 CM2250 engine, providing reliable fuel shutoff.

- ISX15 CM2250: This valve is compatible with the ISX15 CM2250 engine, ensuring precise control over fuel flow.

- ISX15 CM2350 X101: The 4985544 valve fits the ISX15 CM2350 X101 engine, offering dependable fuel shutoff capabilities.

QSX Series

- QSX11.9 CM2250 ECF: The 4985544 valve is compatible with the QSX11.9 CM2250 ECF engine, ensuring reliable fuel shutoff.

- QSX15 CM2250: This valve fits the QSX15 CM2250 engine, providing essential control over fuel delivery.

- QSX15 CM2250 ECF: The 4985544 valve is compatible with the QSX15 CM2250 ECF engine, offering dependable fuel shutoff functionality.

- QSX15 CM2350 X105: This valve fits the QSX15 CM2350 X105 engine, ensuring precise control over fuel flow.

X15 Series

- X15 CM2350 X116B: The 4985544 valve is compatible with the X15 CM2350 X116B engine, providing reliable fuel shutoff capabilities.

This comprehensive compatibility ensures that the Cummins Fuel Shutoff Valve part number 4985544 can be effectively used across a wide range of Cummins engine models, enhancing safety and performance.

Role of Part 4985544 Fuel Shutoff Valve in Engine Systems

In modern engine systems, the integration of the Fuel Shutoff Valve (part 4985544) is essential for maintaining efficient and safe operation. This component works in conjunction with several other systems to ensure optimal performance and emissions control.

Integration with Aftertreatment Devices

The Fuel Shutoff Valve is a key player in the aftertreatment system. It regulates the flow of fuel to the aftertreatment device, which is responsible for reducing harmful emissions. By controlling the fuel supply, the valve helps maintain the correct temperature and chemical reactions within the aftertreatment device, ensuring it operates within specified parameters 2.

Coordination with Doser Fluid Shutoff Valve

In systems where a doser fluid shutoff valve is employed, the Fuel Shutoff Valve operates in tandem to manage the injection of reductant (such as Diesel Exhaust Fluid - DEF) into the exhaust stream. This coordination is vital for the Selective Catalytic Reduction (SCR) process, where the reductant reacts with nitrogen oxides (NOx) to form harmless nitrogen and water. The precise control of fuel and reductant ensures the SCR system functions effectively, reducing emissions while maintaining engine efficiency.

Interaction with Fluid Doser

The Fluid Doser system relies on the Fuel Shutoff Valve to synchronize the dosing of reductant with the fuel injection. This synchronization is important for the proper mixing and reaction of the reductant within the exhaust gases. The valve’s role in this process helps prevent over-dosing or under-dosing, which could lead to inefficiencies or increased emissions.

Overall System Efficiency

By regulating fuel flow, the Fuel Shutoff Valve (part 4985544) contributes to the overall efficiency of the engine system. It ensures that fuel is delivered only when necessary, reducing waste and improving fuel economy. Additionally, its interaction with other components like the aftertreatment device and fluid doser enhances the system’s ability to meet stringent emissions standards while maintaining performance.

Conclusion

The Cummins Fuel Shutoff Valve, part number 4985544, plays a critical role in the efficient and safe operation of heavy-duty trucks. Its precise control over fuel delivery ensures optimal engine performance, enhances safety in emergency situations, and contributes to reduced emissions and improved fuel economy. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this component, ensuring the longevity and reliability of the truck’s engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.