The Cummins Fuel Drain Tube, part number 4969161, is designed to facilitate efficient fuel management in commercial trucks. It allows for the safe and controlled release of fuel from the system, which is crucial for maintenance procedures, system checks, and ensuring the overall health of the fuel system.

Basic Concepts of Fuel Drain Tubes

A Fuel Drain Tube is a component within the fuel system that provides a pathway for fuel to be released. It operates by allowing fuel to flow out when the tube is opened, typically during maintenance or when draining the fuel tank. This process ensures that any contaminants or water that may have accumulated in the fuel can be removed, contributing to efficient fuel management and system integrity 1.

Role of the Fuel Drain Tube in Truck Operation

This Cummins part plays a role in the overall operation of a truck by enabling the periodic draining of fuel. This is important for removing impurities that could otherwise affect engine performance. It interacts with other fuel system components by providing a controlled outlet for fuel, which aids in maintaining the cleanliness and efficiency of the fuel system 2.

Key Features of the Cummins Fuel Drain Tube 4969161

The Cummins Fuel Drain Tube 4969161 is characterized by several features that enhance its performance. These include a durable material composition that resists corrosion and wear, a design that ensures a secure fit within the fuel system, and attributes that facilitate easy operation during fuel draining procedures.

Benefits of Using the Cummins Fuel Drain Tube 4969161

Utilizing this part offers several advantages. It contributes to improved fuel efficiency by allowing for the removal of contaminants from the fuel system. Additionally, it reduces maintenance needs by simplifying the fuel draining process and enhances reliability by ensuring that the fuel system remains clean and operates efficiently 3.

Installation and Integration

Proper installation of the Fuel Drain Tube within the truck’s fuel system is important for optimal performance and compatibility. Guidelines for installation include ensuring a secure fit, proper alignment with other fuel system components, and verifying that all connections are tight to prevent leaks and ensure efficient fuel management.

Maintenance and Troubleshooting

Routine maintenance practices for the Fuel Drain Tube include regular checks for leaks, ensuring that the tube is free from obstructions, and verifying that it operates correctly during fuel draining procedures. Troubleshooting tips for common issues may involve checking for proper installation, ensuring that connections are secure, and addressing any signs of wear or damage promptly.

Safety Considerations

When handling, installing, or maintaining the Fuel Drain Tube, it is important to observe safety guidelines. These include working in a well-ventilated area, avoiding sparks or open flames near the fuel system, and following all manufacturer recommendations for safe operation and maintenance to prevent accidents.

Cummins: A Brief Overview

Cummins Inc. is a company with a history of expertise in diesel engine manufacturing. It is known for its commitment to innovation and quality in the automotive industry. Cummins provides a range of products and services designed to meet the needs of commercial vehicle operators, with a focus on reliability, performance, and efficiency.

Cummins Engine Compatibility with Fuel Drain Tube Part 4969161

The Cummins part number 4969161, a Fuel Drain Tube, is designed to fit seamlessly within the fuel system architecture of specific Cummins diesel engines. This part is integral to the maintenance and operational efficiency of these engines, ensuring that the fuel system remains free from contaminants and moisture, which can otherwise lead to engine performance issues.

QSK38 Series

The QSK38 series engines, specifically the QSK38 CM2150 MCRS and QSK38 CM850 MCRS, are part of Cummins’ high-performance, heavy-duty diesel engine lineup. These engines are engineered for demanding applications, including marine, stationary power, and heavy-duty transportation. The Fuel Drain Tube part 4969161 is meticulously engineered to integrate with the fuel system of these engines, facilitating the removal of water and sediment that can accumulate in the fuel tank. This ensures that the fuel supply to the engine remains clean and uncontaminated, which is crucial for maintaining optimal engine performance and longevity.

Integration and Functionality

The integration of the Fuel Drain Tube part 4969161 within the QSK38 series engines is a critical aspect of their maintenance. This part is strategically placed within the fuel system to allow for easy access and maintenance. Its design ensures that it can effectively perform its function without requiring extensive modifications to the engine’s existing fuel system architecture. This compatibility is essential for ensuring that the engine continues to operate at peak efficiency, even in challenging environments where contamination of the fuel supply is a significant concern.

Importance of the Fuel Drain Tube

The role of the Fuel Drain Tube part 4969161 cannot be overstated. In the context of the QSK38 series engines, this part is vital for maintaining the integrity of the fuel system. By allowing for the regular removal of water and sediment, it helps to prevent issues such as engine stalling, reduced power output, and increased wear on engine components. This is particularly important for engines operating in environments where the quality of the fuel supply may be variable, such as in marine applications where the fuel can pick up water and other contaminants.

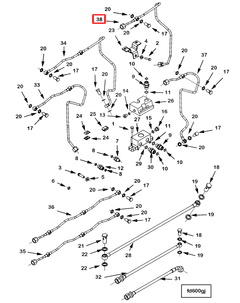

Role of Part 4969161 Fuel Drain Tube in Fuel Drain Plumbing

The 4969161 Fuel Drain Tube is an integral component within the fuel drain plumbing system of an engine. It facilitates the safe and efficient removal of fuel from the system, ensuring that any excess or contaminated fuel is directed away from the engine and into a designated collection area.

In the context of fuel drain plumbing, the Fuel Drain Tube interfaces with several key components:

-

Fuel Tank: The tube is connected to the fuel tank, allowing for the drainage of fuel that may have accumulated sediment or water, which can otherwise lead to engine performance issues.

-

Drain Valve: Often, the Fuel Drain Tube is linked to a drain valve, which controls the flow of fuel out of the system. This valve is typically operated manually or automatically, depending on the system design.

-

Collection Container: The tube directs the drained fuel into a collection container, which is essential for safe disposal or recycling of the fuel. This prevents environmental contamination and ensures compliance with safety regulations.

-

Fuel Lines: The Fuel Drain Tube may also connect to the main fuel lines, providing a pathway for fuel to be drained from various points within the fuel system. This is particularly important in systems where fuel may pool or where there are multiple fuel tanks.

-

Sensors and Monitoring Systems: In more advanced systems, the Fuel Drain Tube may be integrated with sensors that monitor the quality and quantity of the drained fuel. This data can be used to inform maintenance schedules and ensure the engine operates within optimal parameters.

The effective functioning of the 4969161 Fuel Drain Tube within these components ensures that the fuel system remains clean and efficient, contributing to the overall reliability and performance of the engine.

Conclusion

The Cummins part number 4969161, a Fuel Drain Tube, is a critical component for the QSK38 series engines, including the QSK38 CM2150 MCRS and QSK38 CM850 MCRS. Its design and integration within the fuel system of these engines ensure that the fuel supply remains clean and uncontaminated, which is essential for maintaining optimal engine performance and longevity. This part’s importance in the maintenance and operation of these engines underscores the importance of using genuine Cummins parts for maintenance and repair.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.