The Cummins 4969159 Fuel Drain Tube is a component designed for use in heavy-duty trucks, specifically within the QSK38 CM2150 MCRS and QSK38 CM850 MCRS engines. It serves a critical function within the fuel system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and operation is key to maintaining the fuel system’s integrity and performance 1.

Basic Concepts of Fuel Drain Tubes

A fuel drain tube is a component within the fuel system that facilitates the removal of excess fuel. Its operation ensures that the fuel system remains free of contaminants and operates efficiently. By allowing for the drainage of fuel, it helps maintain the cleanliness of the system and prevents the buildup of impurities that could otherwise affect engine performance 2.

Purpose of the Cummins 4969159 Fuel Drain Tube

This Cummins part plays a role in the fuel system by providing a means to drain excess fuel. This function is vital for maintaining the cleanliness of the fuel system and ensuring that the fuel delivered to the engine is free from contaminants. By facilitating the removal of excess fuel, it contributes to the efficient operation of the truck’s fuel system 3.

Key Features

The 4969159 is constructed from materials that ensure durability and reliability. Its design incorporates elements that enhance its performance, such as precise fittings that ensure a secure connection within the fuel system. Additionally, it may feature unique attributes that distinguish it from other fuel drain tubes, such as enhanced resistance to fuel-related wear and corrosion.

Benefits

The use of the Fuel Drain Tube offers several advantages. It contributes to improved fuel system efficiency by ensuring that the fuel delivered to the engine is clean and free from contaminants. This can lead to enhanced overall performance of the truck’s fuel system. Additionally, by facilitating the drainage of excess fuel, it reduces the risk of contamination within the system.

Installation and Integration

Proper installation of this part within a truck’s fuel system is important for its effective operation. This may involve preparations such as ensuring compatibility with the existing fuel system and making any necessary adjustments for seamless integration. Following manufacturer guidelines for installation can help ensure that the fuel drain tube functions as intended.

Maintenance and Troubleshooting

Routine maintenance of the Fuel Drain Tube is important for ensuring its longevity and optimal performance. This may include regular inspections for signs of wear or damage, as well as cleaning to remove any buildup that could affect its operation. Troubleshooting common issues, such as leaks or blockages, can help maintain the efficiency of the fuel system.

Cummins Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industry, known for its range of products that include engines, filtration systems, and components like the 4969159. With a history of innovation and a commitment to quality, Cummins has built a reputation for delivering reliable and high-performance products to the market 4.

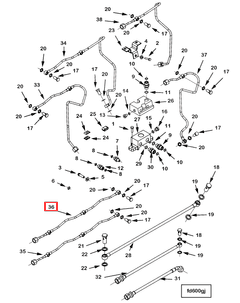

Role of Part 4969159 Fuel Drain Tube in Fuel Drain Plumbing

This part is an essential component within the fuel drain plumbing system of an engine. Its primary function is to facilitate the safe and efficient removal of excess fuel from the fuel system. This process is integral to maintaining the overall performance and safety of the engine.

In the fuel drain plumbing, the Fuel Drain Tube is connected to the fuel tank and the fuel drain valve. When the fuel drain valve is activated, typically during maintenance procedures or in response to a fault condition, the Fuel Drain Tube provides a dedicated pathway for the fuel to exit the system. This helps prevent fuel overflow and reduces the risk of fuel-related hazards.

The Fuel Drain Tube also interfaces with the fuel drain collection system, which may include a collection tank or a drainage point designed to safely handle the expelled fuel. This integration ensures that the fuel is directed away from sensitive engine components and the surrounding environment, enhancing both operational safety and environmental protection.

Furthermore, the Fuel Drain Tube works in conjunction with sensors and control units within the fuel system. These components monitor fuel levels and system pressures, signaling the need for fuel drainage when necessary. The efficient operation of the Fuel Drain Tube is therefore vital for the proper functioning of these monitoring and control systems.

Conclusion

In summary, the 4969159 plays a significant role in the fuel drain plumbing by providing a reliable means for fuel evacuation, ensuring system integrity, and contributing to the safe and efficient operation of the engine. Its proper installation, maintenance, and integration within the fuel system are essential for the optimal performance of heavy-duty trucks.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng, Automotive Heating Ventilation and Air Conditioning, Jones Bartlett Learning, 2018.

↩ -

Haoran Hu, Rudy Smaling, and Simon Baseley, Heavy-Duty Wheeled Vehicles, SAE International, 2014.

↩ -

Qianfan Xin, Diesel Engine System Design, Woodhead Publishing, 2011.

↩ -

Cummins Inc., Owners Manual for L9 CM2670 L136C, Bulletin Number 5579960.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.