Introduction

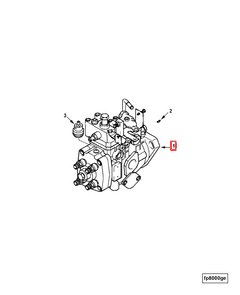

The Cummins 4901017 Fuel Injection Pump is a critical component for heavy-duty trucks, essential for the efficient operation of diesel engines. This part ensures precise fuel delivery to the engine cylinders, optimizing combustion, performance, and emissions control.

Basic Concepts of Fuel Injection Pumps

Fuel injection pumps are engineered to deliver fuel to diesel engines under high pressure. They operate on the principle that diesel fuel ignites when sprayed into compressed air within the engine cylinder. Mechanical systems use physical components to regulate fuel flow, while electronic systems utilize sensors and computer controls for more precise management. The precision of fuel delivery directly impacts engine performance, fuel efficiency, and emissions 1.

Operation of the Cummins 4901017 Fuel Injection Pump

This Cummins part operates through a cam-driven plunger system that pressurizes fuel as the engine runs. Pressurized fuel is then delivered to the injectors, which spray it into the cylinders at the optimal time for combustion. The timing of fuel delivery is crucial for engine efficiency and performance 2.

Purpose and Role in Truck Operation

In heavy-duty trucks, the Cummins 4901017 Fuel Injection Pump ensures that fuel is delivered to the engine in a manner that maximizes performance, fuel efficiency, and emissions control. It plays a vital role in maintaining the balance between power output and fuel consumption, as well as in meeting emissions standards.

Key Features

The Cummins 4901017 Fuel Injection Pump is characterized by its robust design and the use of high-quality materials, ensuring durability and reliability under demanding conditions. It incorporates technological advancements such as precision-machined components and advanced sealing technologies.

Benefits

Utilizing the Cummins 4901017 Fuel Injection Pump offers several benefits, including improved engine performance through precise fuel delivery, enhanced fuel efficiency due to optimal combustion, and reduced emissions as a result of efficient fuel use and combustion 3.

Troubleshooting Common Issues

Identifying and troubleshooting common problems with the Cummins 4901017 Fuel Injection Pump involves recognizing symptoms of malfunction, such as irregular engine performance or increased fuel consumption. Diagnostic procedures may include checking fuel pressure, inspecting for leaks, and analyzing engine performance data. Potential solutions range from cleaning or adjusting components to replacing worn parts.

Maintenance Tips

To ensure optimal performance and longevity of the Cummins 4901017 Fuel Injection Pump, regular maintenance is recommended. This includes inspecting the pump for wear and leaks at specified intervals, cleaning components to remove any contaminants, and replacing parts that show signs of wear or failure. Adhering to these maintenance practices helps maintain the efficiency and reliability of the fuel injection system.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to sustainability, Cummins has established itself as a leader in the diesel engine technology sector, offering products that are designed to meet the evolving needs of the transportation and power generation industries.

Cummins Fuel Injection Pump 4901017 Compatibility

The Cummins Fuel Injection Pump 4901017 is designed to fit seamlessly with various Cummins engines, enhancing their efficiency and reliability. This part is compatible with several engine models, including the A2300 series, ensuring precise fuel delivery and optimal engine performance.

Role of Part 4901017 Fuel Injection Pump in Engine Systems

The fuel injection pump, specifically part 4901017, is integral to the operation of diesel engine systems. It works in conjunction with several key components to ensure efficient fuel delivery and combustion.

Interaction with the Fuel System

- Fuel Tank: The pump draws diesel fuel from the tank, which serves as the primary storage for the fuel.

- Fuel Filter: Before reaching the pump, the fuel passes through a filter that removes impurities, ensuring clean fuel is delivered to the injection pump.

- Fuel Lines: These transport the filtered fuel from the tank to the pump and subsequently to the injectors.

Coordination with Engine Components

- Injectors: The pump pressurizes the fuel and sends it to the injectors, which atomize the fuel into the combustion chamber.

- Combustion Chamber: Pressurized fuel is injected into this chamber where it mixes with air and ignites, driving the piston downward.

- Piston and Cylinder: The combustion process pushes the piston down, converting chemical energy into mechanical energy.

Supporting Systems

- Governor: This component regulates the pump’s output to maintain consistent engine speed under varying loads.

- Timing Mechanism: Ensures that fuel injection occurs at the precise moment for optimal engine performance and efficiency.

- Sensors and Control Units: Modern systems may include sensors that provide feedback to an engine control unit (ECU), allowing for precise adjustments to fuel delivery based on real-time data.

Maintenance and Performance

Regular maintenance of the fuel injection pump and associated components is essential for sustained engine performance. This includes checking for leaks, ensuring proper fuel pressure, and verifying the timing of fuel delivery.

Conclusion

The Cummins 4901017 Fuel Injection Pump is a key component in the diesel engine’s fuel system, working seamlessly with various components to deliver efficient and reliable performance. Its role in ensuring precise fuel delivery, optimal engine performance, and emissions control makes it indispensable in the operation of heavy-duty trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.