Introduction

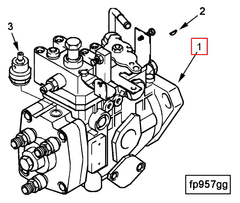

The Cummins 4900554 Fuel Injection Pump is a vital component in the operation of heavy-duty trucks, playing a significant role in the fuel delivery system. This part ensures that fuel is delivered to the engine cylinders at the precise moment and pressure required for efficient combustion, thereby contributing to the overall performance and efficiency of the vehicle 3.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine cylinders at the correct pressure and timing. In diesel engines, this component is particularly important as it ensures that fuel is injected into the combustion chamber at the optimal moment for efficient burning. Fuel injection systems can be mechanical or electronic. Mechanical systems rely on engine-driven pumps and injectors, while electronic systems use sensors and electronic control units to manage fuel delivery. The principles of fuel injection involve precise control over the amount and timing of fuel delivery to maximize engine performance and minimize emissions 1.

Purpose of the 4900554 Fuel Injection Pump

The Cummins 4900554 Fuel Injection Pump is designed to deliver fuel to the engine cylinders with precision. It operates by creating high-pressure fuel that is injected into the combustion chamber at the exact moment needed for efficient combustion. This ensures that the fuel is atomized properly, leading to better mixing with air and more complete burning, which translates to improved engine performance and fuel efficiency 2.

Key Features

The Cummins 4900554 Fuel Injection Pump is characterized by its robust design and high-quality construction materials. It incorporates advanced technological features that enhance its performance and durability. These features include precision-machined components, high-strength materials, and innovative design elements that ensure reliable operation under demanding conditions. The pump’s design allows it to withstand the high pressures and temperatures associated with diesel engine operation, contributing to its longevity and efficiency.

Benefits

The Cummins 4900554 Fuel Injection Pump offers several benefits, including improved fuel efficiency, enhanced engine performance, and reduced emissions. By ensuring precise fuel delivery, the pump helps to optimize combustion, which leads to better fuel economy and increased power output. Additionally, the efficient combustion process results in lower emissions, making the pump an environmentally friendly choice. These benefits are particularly advantageous for truck operators and fleet managers, as they translate to cost savings and improved operational efficiency.

Troubleshooting and Maintenance

Common issues with the Cummins 4900554 Fuel Injection Pump may include leaks, inconsistent fuel delivery, and pump failure. Troubleshooting steps may involve checking for proper fuel pressure, inspecting for leaks, and ensuring that all connections are secure. Routine maintenance practices, such as regular inspection, cleaning, and replacement of worn components, are crucial for ensuring optimal performance and longevity of the pump. Signs of wear or malfunction may include decreased engine performance, unusual noises, or visible leaks, and should be addressed promptly to prevent further damage 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and a strong reputation in the industry, Cummins is committed to producing high-quality diesel engines and components. The company’s dedication to excellence and continuous improvement ensures that its products, including the 4900554 Fuel Injection Pump, meet the highest standards of performance and reliability.

Cummins Fuel Injection Pump 4900554 Compatibility

The Cummins Fuel Injection Pump part number 4900554 is a critical component in the operation of various engines, ensuring precise fuel delivery and optimal engine performance. This part is designed to fit seamlessly with several engine models, enhancing their efficiency and reliability.

A1400 Engine Group

The A1400 engine series, which includes models such as the A1400, is a robust and versatile engine line. The Cummins Fuel Injection Pump 4900554 is engineered to integrate perfectly with these engines, providing the necessary fuel management and control. This compatibility ensures that the A1400 engines operate at peak performance, delivering consistent power and efficiency.

Broader Engine Compatibility

Beyond the A1400 series, the Cummins Fuel Injection Pump 4900554 is also compatible with a range of other engine models. This part’s design allows it to fit various engine architectures, making it a versatile choice for multiple applications. Its ability to work with different engines underscores its importance in maintaining engine performance across a broad spectrum of machinery.

Precision Engineering

The precision engineering of the Cummins Fuel Injection Pump 4900554 ensures that it meets the stringent requirements of modern engines. This part is crafted to deliver accurate fuel metering, which is crucial for the smooth operation of engines. Its compatibility with multiple engine models highlights its reliability and effectiveness in various applications.

Role of Part 4900554 Fuel Injection Pump in Engine Systems

The part 4900554 Fuel Injection Pump is an integral component in the fuel delivery system of an engine. It works in conjunction with several other components to ensure efficient and precise fuel delivery, which is essential for optimal engine performance.

Interaction with the Fuel System

- Fuel Tank: The fuel injection pump draws diesel from the fuel tank. It relies on a consistent fuel supply to maintain the required pressure for injection.

- Fuel Filter: Before the fuel reaches the pump, it passes through the fuel filter. This filter removes impurities and contaminants, ensuring that only clean fuel enters the pump. This is important for the longevity and efficiency of the pump.

- Fuel Lines: The pump is connected to the fuel lines, which transport the fuel from the tank to the pump and from the pump to the injectors. The integrity of these lines is vital for maintaining the necessary pressure and flow rate.

Integration with the Injection System

- Injectors: The primary role of the fuel injection pump is to deliver pressurized fuel to the injectors. The pump pressurizes the fuel to the levels required for the injectors to atomize the fuel properly upon injection into the combustion chamber.

- Common Rail (if applicable): In systems that use a common rail, the pump supplies high-pressure fuel to the rail, which then distributes it to the injectors. This setup allows for more precise control over the fuel injection timing and quantity.

Coordination with Engine Components

- Engine Control Unit (ECU): The ECU monitors various engine parameters and adjusts the fuel injection timing and quantity accordingly. It communicates with the fuel injection pump to ensure that the fuel delivery matches the engine’s needs at any given moment.

- Crankshaft and Camshaft Sensors: These sensors provide the ECU with data on the engine’s speed and position. This information is used to time the fuel injection precisely, enhancing engine efficiency and performance.

- Throttle Position Sensor: This sensor informs the ECU about the position of the throttle. Based on this input, the ECU adjusts the fuel delivery to match the driver’s demand, ensuring smooth and responsive engine operation.

Supporting Components

- Return Lines: Excess fuel that is not injected into the combustion chamber is returned to the tank via return lines. This helps in maintaining the desired pressure within the fuel system.

- Pressure Regulators: These components work in tandem with the fuel injection pump to maintain consistent fuel pressure, which is crucial for the injectors to function correctly.

Conclusion

In summary, the Cummins 4900554 Fuel Injection Pump is a key player in the fuel delivery system, interacting with various components to ensure that the engine receives the right amount of fuel at the right time, under the right pressure. This coordinated effort is essential for the engine’s efficiency, performance, and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.