This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

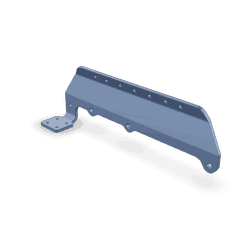

The Fuel Plumbing Bracket (Part #4368212) by Cummins is a component designed to support and organize the fuel lines in commercial trucks. Its role is significant in maintaining the integrity and efficiency of the fuel delivery system, ensuring that fuel is transported safely and effectively from the tank to the engine 1.

Purpose and Function

The Fuel Plumbing Bracket serves to secure and organize the fuel lines within the truck’s fuel system. By providing a structured pathway for the fuel lines, it helps maintain the alignment and integrity of the lines, which is vital for efficient and safe fuel delivery to the engine. This bracket plays a role in reducing the risk of fuel line damage due to vibrations or movement, thereby contributing to the overall reliability of the fuel system 2.

Key Features

The design of the Fuel Plumbing Bracket includes several mounting points that allow for secure attachment to the truck’s frame. It is constructed from materials that offer resistance to environmental factors such as corrosion and extreme temperatures, ensuring durability in various operating conditions. The bracket is compatible with a range of fuel lines, accommodating different diameters and configurations to suit various truck models and fuel systems 3.

Benefits

Incorporating the Fuel Plumbing Bracket into a truck’s fuel system offers several advantages. It enhances the reliability of the fuel system by providing a stable and organized route for the fuel lines. This organization reduces the likelihood of fuel leaks, which can be hazardous and lead to inefficient fuel consumption. Additionally, the bracket simplifies maintenance procedures by allowing for easier access to the fuel lines for inspection and repair 4.

Installation and Compatibility

Proper installation of the Fuel Plumbing Bracket is crucial for its effective function. It should be securely fastened to the truck’s frame using the provided mounting points. The bracket is designed to be compatible with a variety of truck models and fuel systems, ensuring that it can be integrated into different setups without requiring significant modifications.

Maintenance and Troubleshooting

Regular inspection of the Fuel Plumbing Bracket is recommended to ensure its continued effectiveness. This includes checking for signs of wear, corrosion, or damage to the bracket and the fuel lines it supports. Common issues may include loose mounting points or damaged fuel lines, which can be addressed by tightening fasteners or replacing damaged components as necessary.

Safety Considerations

When working with the Fuel Plumbing Bracket and the fuel system, it is important to follow safety practices to prevent fuel leaks and ensure safe operation. This includes wearing appropriate personal protective equipment, ensuring the fuel system is depressurized before beginning work, and following manufacturer guidelines for installation and maintenance.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its commitment to quality and innovation in truck component manufacturing. With a history of producing reliable and high-performance parts, Cummins has built a reputation for excellence, providing truck operators with components that enhance the efficiency and durability of their vehicles.

Cummins Fuel Plumbing Bracket 4368212 Compatibility

The Cummins Fuel Plumbing Bracket part number 4368212 is designed to be a versatile component that fits seamlessly into various engine configurations. This bracket is engineered to support and secure fuel lines, ensuring that the fuel delivery system operates efficiently and safely.

QST30 and CM2350 Engines

For the QST30 and CM2350 engines, the 4368212 bracket is specifically tailored to fit the unique layout and requirements of these models. It provides a robust mounting point for fuel lines, ensuring they remain properly aligned and secured throughout the engine’s operational cycles. This bracket is critical in maintaining the integrity of the fuel system, preventing leaks and ensuring consistent fuel flow.

T101 Engine

The T101 engine also benefits from the 4368212 bracket, which is designed to integrate smoothly with the engine’s architecture. This bracket ensures that fuel lines are held in place, reducing the risk of disconnection or damage due to engine vibrations or movement. Its precise fitment is crucial for the T101 engine’s performance, as it supports the fuel system’s reliability and efficiency.

Grouping of Engines

When considering the QST30, CM2350, and T101 engines together, the 4368212 bracket demonstrates its versatility and adaptability. Despite the differences in engine design and specifications, this bracket is engineered to fit all three models, providing a standardized solution for fuel plumbing needs. This compatibility highlights the bracket’s design flexibility and its ability to meet the diverse requirements of different engine types.

Role of Part 4368212 Fuel Plumbing Bracket in Engine Systems

This Cummins part is an integral component in the fuel delivery system of various engine setups. Its primary function is to secure and organize the fuel lines, ensuring a stable and efficient fuel supply to the engine.

Integration with Fuel Supply System

In the fuel supply system, this part plays a significant role by providing a mounting point for the fuel lines. This bracket is typically attached to the engine block or chassis, allowing the fuel lines to be routed in a manner that minimizes stress and potential wear. By securing the fuel lines, the bracket helps maintain consistent fuel pressure and flow, which is essential for the engine’s performance and reliability.

Interaction with Fuel Plumbing

When it comes to fuel plumbing, the Fuel Plumbing Bracket ensures that the fuel lines are correctly positioned and supported. This is particularly important in high-vibration environments, such as those found in automotive or aerospace applications. The bracket helps to absorb some of the vibrations that could otherwise lead to fuel line fatigue or disconnection. Additionally, it allows for easier access during maintenance, enabling technicians to quickly inspect or replace fuel lines as needed.

Enhanced System Efficiency

By providing a structured path for the fuel lines, the Fuel Plumbing Bracket contributes to the overall efficiency of the fuel system. It helps prevent kinks or sharp bends in the fuel lines, which can restrict fuel flow and lead to engine performance issues. Moreover, the organized routing of fuel lines reduces the risk of interference with other engine components, ensuring a smoother operation of the entire system.

Safety and Reliability

The secure attachment of fuel lines via the Fuel Plumbing Bracket also enhances the safety and reliability of the engine system. In the event of an accident or sudden movement, the bracket helps to keep the fuel lines intact, reducing the risk of fuel leaks. This is a vital safety feature, especially in applications where fuel system integrity is paramount.

Conclusion

In summary, the 4368212 Fuel Plumbing Bracket is a key component in maintaining the integrity and efficiency of the fuel supply and plumbing systems within an engine. Its role in securing and organizing fuel lines ensures consistent fuel delivery, enhances system reliability, and contributes to overall engine performance.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Gifford, C. (2014). Cars Encyclopedia. DK Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.