4328544

Fuel Flow Limiting Orifice

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

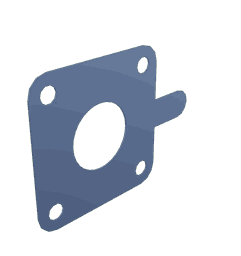

The Fuel Flow Limiting Orifice, identified by part number 4328544, is a component manufactured by Cummins, a leader in the automotive and heavy-duty truck industry. This part plays a role in the fuel system of heavy-duty truck engines, contributing to their performance, efficiency, and emissions control 1.

Basic Concepts

The Fuel Flow Limiting Orifice operates by restricting the flow of fuel within the engine system. This regulation is achieved through the orifice’s design, which creates a fixed restriction in the fuel line, helping maintain optimal fuel pressure and flow for efficient combustion and engine operation 2.

Purpose and Function

In heavy-duty truck engines, the Fuel Flow Limiting Orifice regulates the amount of fuel that reaches the engine. This regulation is vital for ensuring that the engine operates within its designed parameters, contributing to its performance, efficiency, and emissions control. By limiting the fuel flow, the orifice helps prevent overfueling, which can lead to inefficient combustion, increased emissions, and potential engine damage 3.

Key Features

The Fuel Flow Limiting Orifice is characterized by its precise design and construction. Made from high-quality materials, it is engineered to withstand the harsh conditions of heavy-duty truck engines. Its unique attributes include a specific orifice size that is calibrated to match the engine’s fuel requirements, ensuring optimal performance and efficiency.

Benefits

The use of a Fuel Flow Limiting Orifice in heavy-duty truck engines offers several benefits. It contributes to improved fuel economy by ensuring that fuel is delivered to the engine in the correct amounts, reducing waste and inefficiency. Additionally, by regulating fuel flow, it helps reduce emissions, contributing to a cleaner environment. Furthermore, the orifice enhances overall engine reliability by preventing overfueling, which can lead to engine wear and damage.

Installation and Maintenance

Proper installation and maintenance of the Fuel Flow Limiting Orifice are important for ensuring its optimal performance and longevity. Installation should be carried out according to the manufacturer’s guidelines, ensuring that the orifice is correctly positioned and secured in the fuel line. Regular maintenance, including inspection for signs of wear or damage, is recommended to ensure continued efficient operation.

Troubleshooting

Common issues with the Fuel Flow Limiting Orifice may include blockages or damage to the orifice, leading to improper fuel flow. Troubleshooting steps may involve inspecting the orifice for signs of damage or blockage, and replacing it if necessary. Ensuring that the fuel system is clean and free from contaminants can also help prevent issues with the orifice.

Cummins Overview

Cummins is a global leader in the design, manufacture, and distribution of engines and related technologies. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and efficient engine components. Their Fuel Flow Limiting Orifice is a testament to their dedication to enhancing engine performance and efficiency in heavy-duty applications.

Role of Part 4328544 Fuel Flow Limiting Orifice in Engine Systems

Integration with the Arrangement

In the overall arrangement of the engine system, the Fuel Flow Limiting Orifice is strategically positioned to regulate the fuel flow rate. This ensures that the fuel delivery is consistent and within the specified parameters, which is vital for maintaining engine performance and preventing overfueling.

Interaction with the Pressure Regulator Valve

The Pressure Regulator Valve works in conjunction with the Fuel Flow Limiting Orifice to maintain the desired fuel pressure. The orifice restricts the flow of fuel, allowing the pressure regulator to adjust the pressure levels accurately. This synergy ensures that the engine receives a steady fuel supply at the correct pressure, enhancing combustion efficiency and reducing the risk of fuel-related issues.

Role in the Fuel Transfer Kit

Within the Fuel Transfer Kit, the Fuel Flow Limiting Orifice plays a significant role in controlling the transfer of fuel between tanks or systems. By limiting the flow rate, it prevents rapid fuel transfer that could lead to surges or instability in the fuel system. This controlled transfer is essential for maintaining consistent fuel levels and pressure, which is particularly important during engine operation and transitions between different flight phases.

Function in the Fuel Transfer Right Hand Engine Kit

In the Fuel Transfer Right Hand Engine Kit, the orifice ensures that the right-hand engine receives a regulated fuel flow. This is important for balancing the fuel distribution between the engines, especially in multi-engine aircraft. Proper fuel flow management helps in achieving symmetrical thrust, which is critical for stable and efficient flight operations.

Contribution to the Service Kit

When included in a Service Kit, the Fuel Flow Limiting Orifice is often part of routine maintenance to ensure the fuel system’s integrity. Replacing or inspecting this component during servicing helps in identifying potential issues early, such as wear or blockages, which could affect fuel flow and engine performance. This proactive approach to maintenance contributes to the longevity and reliability of the engine system.

Conclusion

The Fuel Flow Limiting Orifice (part 4328544) by Cummins is a critical component in the fuel management system of heavy-duty truck engines. Its precise design and function contribute to optimal engine performance, efficiency, and emissions control. Proper installation, maintenance, and troubleshooting are essential for ensuring the longevity and reliability of this part in various engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.