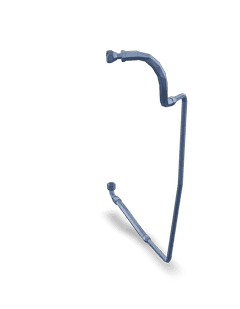

The Cummins 4314255 Fuel Hose is a component designed for use in commercial trucks, manufactured by Cummins Inc. This hose plays a role in the fuel system by facilitating the transfer of fuel from the tank to the engine. Cummins, a well-established name in the automotive industry, ensures that this fuel hose meets the demanding requirements of heavy-duty applications 1.

Basic Concepts of Fuel Hoses

A fuel hose is a conduit used in a vehicle’s fuel system to transport fuel from the tank to the engine. Its function is vital for the continuous operation of the vehicle, ensuring that the engine receives a steady supply of fuel. Fuel hoses are typically constructed from materials that can withstand the chemical properties of fuel, such as rubber, reinforced with textile or wire for added strength and durability 2.

Role of the Cummins 4314255 Fuel Hose in Truck Operation

The Cummins 4314255 Fuel Hose contributes to the efficient operation of a truck’s fuel system by providing a reliable pathway for fuel delivery. It is designed to handle the pressures and temperatures associated with diesel fuel, ensuring that the engine receives a consistent fuel supply under various operating conditions 3.

Key Features of the Cummins 4314255 Fuel Hose

The Cummins 4314255 Fuel Hose incorporates specific design elements and materials that enhance its performance and durability. These features include a robust construction to resist wear and tear, flexibility to accommodate the movement within the truck’s chassis, and compatibility with diesel fuel to prevent degradation over time 4.

Benefits of Using the Cummins 4314255 Fuel Hose

The Cummins 4314255 Fuel Hose offers several advantages, including improved fuel efficiency due to its design that minimizes fuel loss. It also reduces the risk of leaks, thanks to its durable construction and secure fitting design. Furthermore, its enhanced durability ensures a longer service life, contributing to lower maintenance costs 5.

Installation Considerations

When installing the Cummins 4314255 Fuel Hose, it is important to follow guidelines and best practices to ensure optimal performance and safety. This includes proper routing of the hose to avoid sharp bends or abrasion, securing it in place to prevent movement that could lead to wear, and ensuring connections are tight and leak-free 6.

Maintenance and Troubleshooting

Maintaining the Cummins 4314255 Fuel Hose involves regular inspections for signs of wear, cracks, or leaks. Common issues such as blockages can be addressed by checking for obstructions within the hose or at the connection points. Troubleshooting may involve replacing sections of the hose or ensuring that all connections are secure and free from leaks 7.

Safety Precautions

Working with fuel systems requires observing important safety measures. This includes handling fuel with care to avoid spills, ensuring that no sparks are present to prevent ignition, and properly disposing of old hoses to avoid environmental contamination 8.

Environmental Considerations

The environmental impact of fuel hoses is an important consideration. Proper disposal and recycling practices help minimize harm to the environment. Cummins encourages the recycling of old hoses and the use of environmentally friendly materials where possible 9.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation and quality, offering a wide range of products for various industries, including automotive, construction, and power generation 10.

Cummins Fuel Hose 4314255 Compatibility

The Cummins fuel hose part number 4314255 is designed to be compatible with a range of Cummins engines, ensuring a secure and reliable fuel delivery system. This part is engineered to meet the stringent requirements of Cummins’ engine specifications, providing durability and performance across various engine models.

QSK19 and CM2350 Engines

The Cummins QSK19 and CM2350 engines are part of the QSK series, known for their robust design and high performance in industrial and marine applications. The fuel hose 4314255 fits seamlessly with these engines, ensuring efficient fuel transfer and maintaining the integrity of the fuel system. Its compatibility with these engines is critical for optimal engine operation and longevity.

K105 Engine

The Cummins K105 engine is another model where the fuel hose 4314255 is an essential component. This engine is typically used in heavy-duty applications, and the fuel hose ensures that the engine receives a consistent and reliable fuel supply. The design of the hose is tailored to withstand the demanding conditions these engines operate under, providing a dependable connection that minimizes the risk of fuel leaks and system failures.

Grouping for Efficiency

When considering the QSK19, CM2350, and K105 engines together, the fuel hose 4314255 offers a standardized solution for fuel system integrity. This grouping highlights the versatility of the part, which can be used across different engine types, simplifying maintenance and inventory management for operators and service providers. The compatibility of the fuel hose with these engines ensures that maintenance can be performed efficiently, with minimal downtime and reduced costs associated with sourcing specific parts.

Role of Part 4314255 Fuel Hose in Engine Systems

The part 4314255 Fuel Hose is an essential component in the fuel delivery system of various engine setups. It facilitates the transfer of fuel from the fuel tank to the engine’s fuel filter and subsequently to the fuel injectors or carburetor.

In systems equipped with a fuel filter, the hose connects the output side of the filter to the fuel rail or carburetor, ensuring a clean and uninterrupted fuel supply. This connection is vital for maintaining the efficiency and performance of the engine, as it prevents contaminants from entering the combustion chamber.

Additionally, the fuel hose plays a significant role in managing fuel pressure within the system. It is designed to withstand the pressures generated during fuel delivery, ensuring that the fuel reaches the engine components at the correct pressure for optimal combustion.

The integration of the fuel hose with the fuel filter also enhances the overall reliability of the fuel system. By providing a secure and leak-free connection, it minimizes the risk of fuel leaks, which can be hazardous and lead to inefficient engine operation.

Conclusion

In summary, the part 4314255 Fuel Hose is a key element in ensuring the smooth and efficient operation of the fuel delivery system, working in conjunction with the fuel filter to deliver clean, pressurized fuel to the engine.

-

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ -

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.