4093928

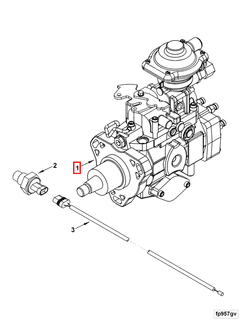

Fuel Injection Pump

Cummins®

DISCONTINUED

This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4093928 Fuel Injection Pump is a component designed for use in commercial trucks. It plays a role in the operation of these vehicles by ensuring that fuel is delivered to the engine at the correct timing and pressure. This part is integral to the efficient and reliable performance of diesel engines found in heavy-duty trucks.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that pressurizes fuel and delivers it to the engine’s combustion chambers. In diesel engines, this pump operates by creating high-pressure fuel that is injected into the cylinders at precise moments in the engine cycle. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and linkages to control fuel delivery, while electronic systems use sensors and computer controls to manage injection timing and quantity more precisely 1.

Purpose of the Cummins 4093928 Fuel Injection Pump

The Cummins 4093928 Fuel Injection Pump is responsible for delivering fuel to the engine at the exact moment and pressure required for optimal combustion. This precise delivery ensures that the engine operates efficiently, with minimal waste and maximum power output. The pump’s role is in maintaining the balance between fuel consumption and engine performance.

Key Features

The Cummins 4093928 Fuel Injection Pump is characterized by its robust design and the use of high-quality materials. It incorporates advanced technological features that enhance its performance and reliability. These features include precision-machined components, durable seals, and a design that minimizes internal leakage, ensuring consistent fuel delivery 2.

Benefits

The use of the Cummins 4093928 Fuel Injection Pump offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is used effectively during combustion. Additionally, it enhances engine performance by providing consistent and precise fuel delivery. The pump’s reliable operation is also a significant benefit, contributing to the overall durability and longevity of the engine 3.

Installation and Integration

Installing the Cummins 4093928 Fuel Injection Pump requires careful consideration of the truck’s specific engine configuration. It may necessitate modifications or adjustments to ensure proper fit and function. Following manufacturer guidelines during installation is important to maintain the pump’s performance and compatibility with the engine system.

Maintenance and Service

Regular maintenance of the Cummins 4093928 Fuel Injection Pump is vital to ensure its longevity and optimal performance. This includes periodic inspections, cleaning, and the replacement of worn components. Adhering to recommended service intervals and procedures helps prevent issues and maintains the pump’s efficiency.

Troubleshooting Common Issues

Common problems with the Cummins 4093928 Fuel Injection Pump may include leaks, irregular fuel delivery, and performance issues. These can often be traced back to worn seals, clogged filters, or electrical faults in the case of electronic systems. Addressing these issues promptly with the appropriate repairs or replacements can restore the pump’s function.

Performance Enhancements

To further improve the performance of the Cummins 4093928 Fuel Injection Pump, various upgrades or modifications can be considered. These may include tuning the injection timing or pressure, or installing higher-quality components. Such enhancements can lead to increased engine efficiency and power output.

Safety Considerations

When working with the Cummins 4093928 Fuel Injection Pump, it is important to observe safety practices. This includes proper handling of fuel, using appropriate personal protective equipment, and following maintenance procedures to avoid accidents or injuries.

Environmental Impact

The Cummins 4093928 Fuel Injection Pump plays a role in reducing the environmental impact of commercial trucks. By ensuring efficient fuel combustion, it helps minimize emissions and improve fuel efficiency, contributing to a lower carbon footprint for heavy-duty vehicles.

Cummins Company Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for its commitment to innovation and quality in fuel injection systems. With a rich history of developing reliable and efficient components, Cummins continues to be at the forefront of technological advancements in engine technology.

Role of Part 4093928 Fuel Injection Pump in Engine Systems

The part 4093928 Fuel Injection Pump is integral to the efficient operation of engine systems by precisely delivering fuel into the combustion chamber. This component works in conjunction with several other engine components to ensure optimal performance and fuel efficiency.

Interaction with the Common Rail System

In engines equipped with a common rail fuel system, the Fuel Injection Pump plays a significant role in maintaining high-pressure fuel delivery. It pressurizes fuel and stores it in the common rail, from where it is distributed to individual injectors. The pump ensures that fuel is delivered at the correct pressure and timing, which is essential for the injectors to atomize fuel properly during the combustion process.

Coordination with Fuel Injectors

The Fuel Injection Pump works hand-in-hand with fuel injectors. Once the pump pressurizes the fuel, injectors spray it into the combustion chamber in a finely atomized state. This precise delivery is vital for achieving the desired air-fuel mixture, which directly impacts engine performance, emissions, and fuel economy.

Integration with the Engine Control Unit (ECU)

The Fuel Injection Pump is often controlled by the Engine Control Unit (ECU). The ECU monitors various engine parameters such as load, speed, and temperature. Based on this data, it sends signals to the pump to adjust fuel delivery accordingly. This dynamic interaction ensures that the engine operates efficiently under varying conditions.

Relationship with the High-Pressure Fuel Pump (HPFP)

In some engine configurations, the Fuel Injection Pump may be part of a High-Pressure Fuel Pump (HPFP) system. The HPFP boosts the pressure of the fuel before it reaches the common rail. The Fuel Injection Pump ensures that this high-pressure fuel is delivered consistently, maintaining engine performance and reliability.

Synergy with the Turbocharger

In turbocharged engines, the Fuel Injection Pump must work in sync with the turbocharger. As the turbocharger increases air density in the combustion chamber, the pump must deliver a corresponding increase in fuel to maintain the correct air-fuel ratio. This balanced delivery is essential for maximizing power output and ensuring smooth engine operation.

Collaboration with the Exhaust Gas Recirculation (EGR) System

The Fuel Injection Pump also interacts with the Exhaust Gas Recirculation (EGR) system. When EGR is active, a portion of the exhaust gas is recirculated back into the intake tract to reduce nitrogen oxides (NOx) emissions. The pump must adjust fuel delivery to compensate for the change in the air-fuel mixture caused by the recirculated exhaust gases.

Impact on the Aftertreatment System

Finally, the Fuel Injection Pump influences the aftertreatment system, which includes components like the Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) system. Proper fuel delivery ensures that the engine runs cleanly, reducing the load on these aftertreatment components and prolonging their lifespan.

Conclusion

In summary, the Cummins 4093928 Fuel Injection Pump is a key component that interacts with various engine systems to ensure efficient and reliable operation. Its role in fuel delivery is fundamental to the performance, efficiency, and emissions control of modern engines.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.