This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4080716 Fuel-Water Separator is designed to enhance the operation of commercial trucks by ensuring the fuel delivered to the engine is free from water and contaminants. This part is integral to maintaining the efficiency and reliability of diesel engines, which are commonly used in heavy-duty applications 2.

Basic Concepts of Fuel-Water Separators

A fuel-water separator removes water and other impurities from diesel fuel before it reaches the engine. This is achieved through a filtration process where the fuel passes through materials that trap water and contaminants. The separated water typically collects at the bottom of the separator, where it can be drained away. This process is vital for diesel engines, as water in the fuel can lead to corrosion, reduced efficiency, and potential engine damage 1.

Purpose of the Cummins 4080716 Fuel-Water Separator

The Cummins 4080716 Fuel-Water Separator ensures that the fuel supplied to the engine is clean and dry. This contributes to maintaining engine performance and extending its operational life by preventing issues associated with water contamination in the fuel. By removing water and impurities, the separator helps in achieving more efficient combustion and reducing the wear on engine components 2.

Key Features

The Cummins 4080716 Fuel-Water Separator is characterized by its robust design and the use of high-quality materials. It incorporates advanced filtration technology to effectively separate water from fuel. The separator is also designed for ease of maintenance, with features that allow for straightforward draining of accumulated water and replacement of filter elements when necessary 2.

Benefits of Using a Fuel-Water Separator

Incorporating a fuel-water separator into a truck’s fuel system offers several advantages. It improves engine efficiency by ensuring cleaner fuel combustion. Additionally, it reduces maintenance costs by minimizing the risk of engine damage from water contamination. Enhanced fuel quality leads to better overall performance and reliability of the vehicle 1.

Installation and Integration

Proper installation of the Cummins 4080716 Fuel-Water Separator involves integrating it into the truck’s fuel system in a manner that ensures compatibility with existing components. It is important to follow manufacturer guidelines to ensure the separator is correctly positioned and connected, allowing for optimal performance and efficiency 2.

Maintenance and Service Intervals

Routine maintenance of the Cummins 4080716 Fuel-Water Separator is crucial for its optimal performance. Regular checks and replacements of filter elements are recommended, along with periodic draining of accumulated water. Adhering to service intervals helps in maintaining the separator’s effectiveness and prolonging its operational life 1.

Troubleshooting Common Issues

Common problems associated with fuel-water separators include reduced efficiency due to clogged filters or accumulation of water. Troubleshooting steps may involve checking the filter element for blockages, ensuring proper drainage of water, and verifying the separator’s integration within the fuel system. Recognizing signs of malfunction early and taking appropriate corrective actions can prevent more significant issues 1.

Compatibility with Cummins Engines

The 4080716 Fuel-Water Separator is specifically designed to fit seamlessly with several Cummins engine models. Here are some of the engines where this part is applicable:

-

6B5.9 Series: This part is compatible with the 6B5.9 engine series, ensuring that the fuel supplied to the engine is free from water and other impurities. The 6B5.9 engines are known for their robust performance and reliability, making them a popular choice in various industrial applications.

-

Other Cummins Engines: While the 4080716 is prominently used with the 6B5.9 series, it is also compatible with other Cummins engines that require a high-quality fuel-water separator. Cummins engines are renowned for their durability and efficiency, and the 4080716 part plays a crucial role in maintaining these standards by ensuring the fuel remains clean and free from contaminants 2.

Integration with Fuel System Components

-

Fuel Supply Line: The separator is typically installed in the fuel supply line, where it intercepts the fuel flow early in the system. As fuel passes through the separator, any water present is directed to a collection area, while clean fuel continues its journey.

-

Fuel Filter: Post-separation, the fuel moves towards the fuel filter. With water and contaminants already removed by the 4080716, the filter’s efficiency is enhanced, as it no longer has to deal with water-laden fuel. This results in prolonged filter life and more effective filtration of particulate matter.

-

Fuel Injection System: Clean, dry fuel is essential for the proper operation of fuel injectors. The 4080716 ensures that the fuel delivered is free from water, which can cause corrosion and damage to injectors over time. This leads to more precise fuel delivery and improved engine performance.

-

Combustion Process: The quality of fuel directly impacts the combustion process within the engine. By ensuring that water is not present in the fuel, the 4080716 helps maintain consistent combustion, which is vital for engine efficiency and power output.

-

Engine Longevity: Over time, the accumulation of water in the fuel system can lead to corrosion and other forms of degradation. The 4080716 plays a significant role in preventing such issues, thereby contributing to the overall longevity of the engine 2.

Conclusion

The Cummins 4080716 Fuel-Water Separator is a key component in maintaining the integrity of the fuel supply within engine systems. Its placement ahead of the fuel filter and its role in protecting downstream components underscore its importance in ensuring efficient and reliable engine operation.

SPECIFICATIONS

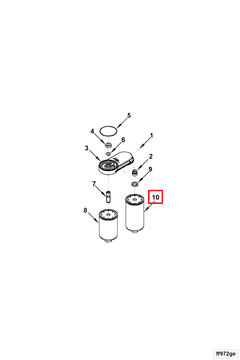

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.